Oxyfuel Boiler and Control Method for Oxyfuel Boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

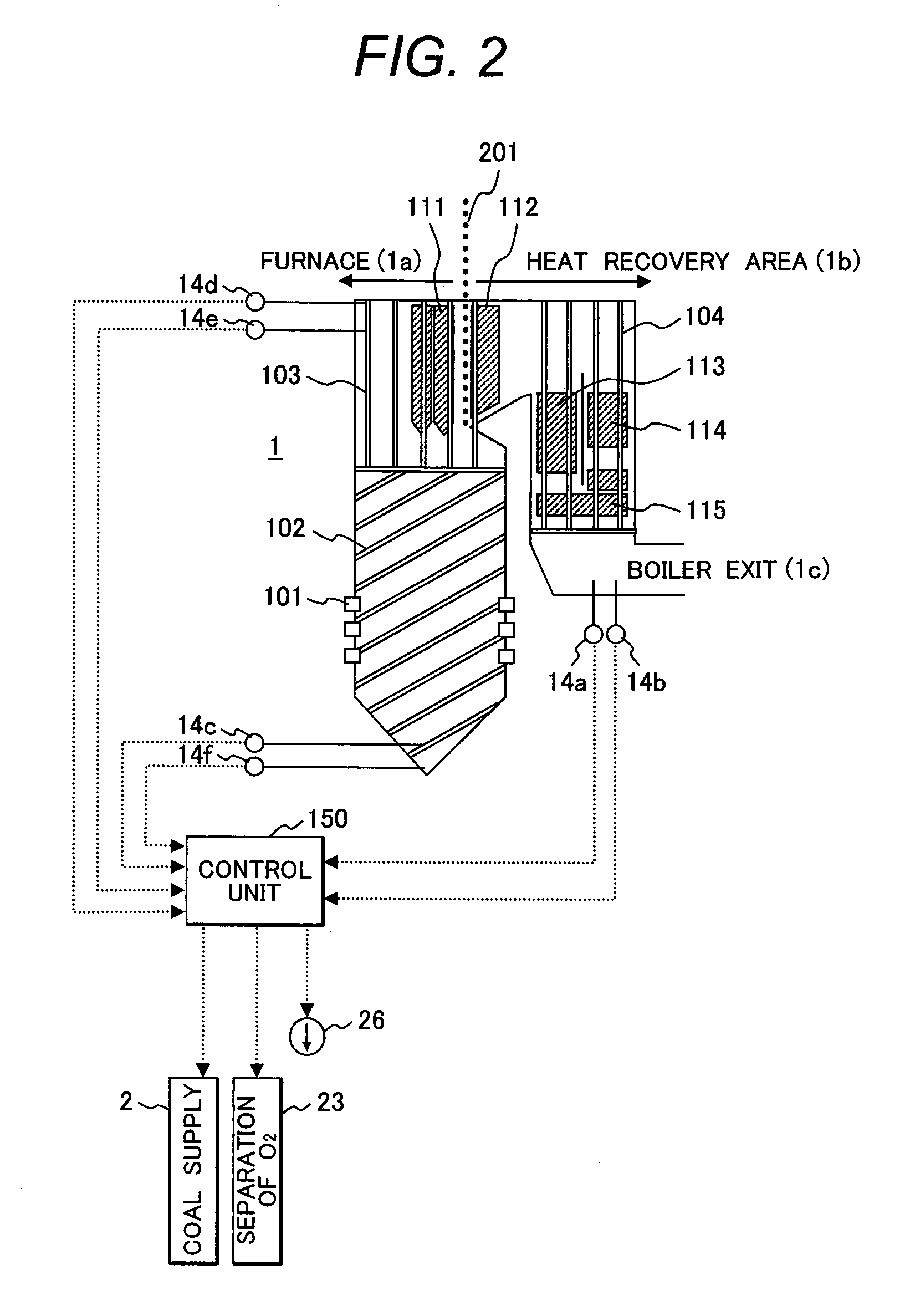

[0039]The oxyfuel boiler that is a first embodiment of the present invention and the control method for the oxyfuel boiler will be explained below by referring to FIGS. 1 to 5.

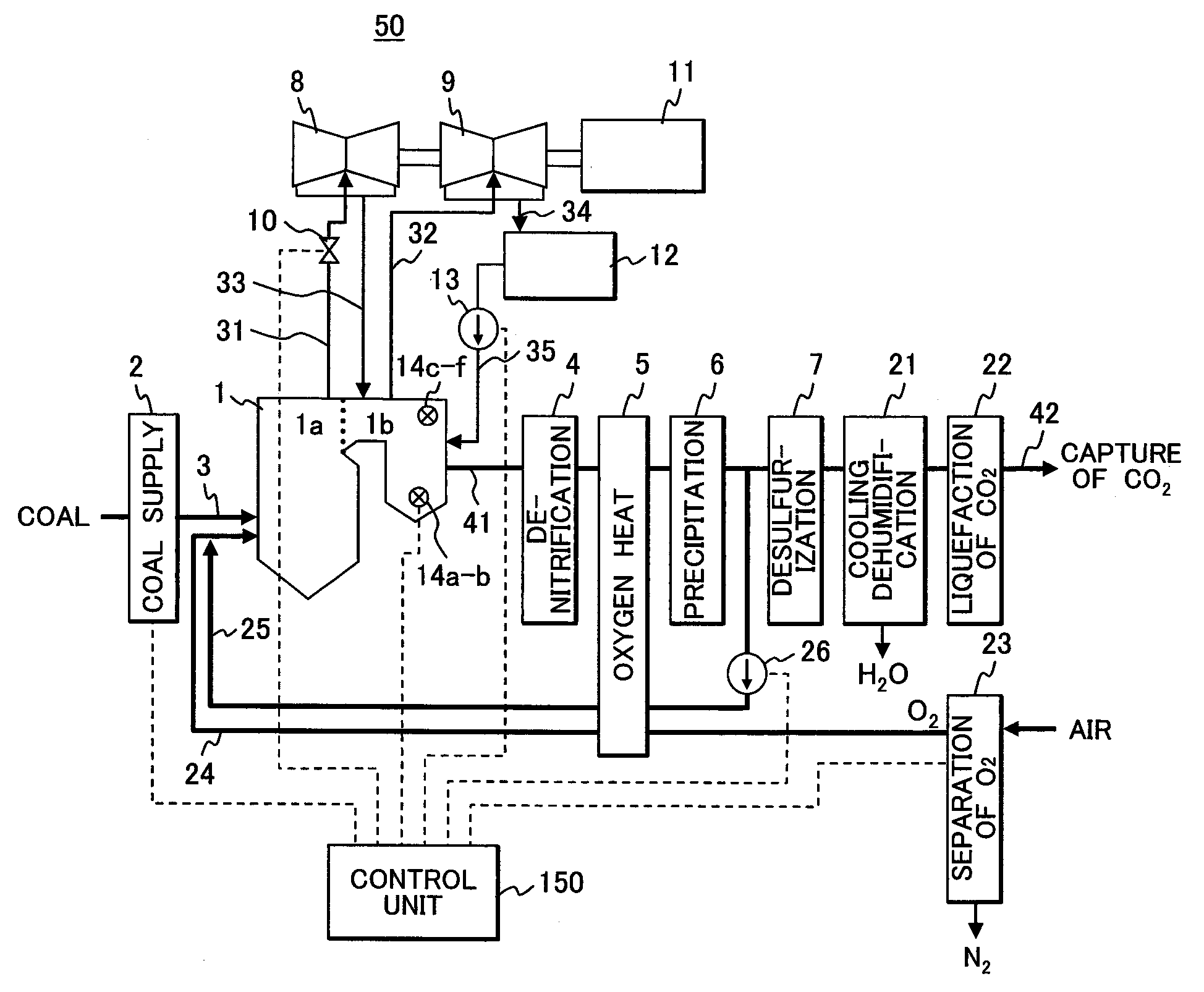

[0040]FIG. 1 is a schematic constitution showing the constitution of the coal thermal power plant suitable for CO2 capture having the oxyfuel boiler that is a first embodiment of the present invention.

[0041]The coal thermal power plant having the oxyfuel boiler which is a first embodiment of the present invention includes an oxyfuel boiler 1 for burning pulverized coal as fuel by oxygen separately supplied by the coal boiler. The oxyfuel boiler 1 has the same structure as that of an ordinary air-fuel boiler for burning pulverized coal as fuel by supplying air.

[0042]In the oxyfuel boiler 1, coal as fuel is pulverized to pulverized coal by a coal supply unit 2 and the pulverized coal is supplied to the oxyfuel boiler 1 via a coal supply system 3 from the coal supply unit 2 and is burnt together with oxygen separ...

embodiment 2

[0136]Next, the oxyfuel boiler which is a second embodiment of the present invention and the control method for the oxyfuel boiler will be explained below by referring to FIGS. 6 and 7.

[0137]FIG. 6 is a schematic cross sectional view showing the constitution of the coal thermal power plant suitable for CO2 capture having the oxyfuel boiler that is a second embodiment of the present invention.

[0138]The oxyfuel boiler 1 of the second embodiment of the present invention has a basic constitution substantially similar to that of the oxyfuel boiler 1 of the first embodiment of the present invention shown in FIGS. 1 to 5, so that the explanation of the portions of the constitution common to both will be omitted and only the different portions of the constitution will be explained below.

[0139]In the oxyfuel boiler 1 of the second embodiment of the present invention shown in FIGS. 6 and 7, compared with the oxyfuel boiler of the first embodiment shown in FIGS. 1 to 5, the constitution using ...

embodiment 3

[0154]Next, the oxyfuel boiler which is a third embodiment of the present invention and the control method for the oxyfuel boiler will be explained below by referring to FIGS. 8 and 9.

[0155]FIG. 8 is a schematic cross sectional view showing the constitution of the coal thermal power plant suitable for CO2 capture having the oxyfuel boiler which is a third embodiment of the present invention.

[0156]The oxyfuel boiler 1 of the third embodiment of the present invention has a basic constitution substantially similar to that of the oxyfuel boiler 1 of the second embodiment of the present invention shown in FIGS. 6 and 7, so that the explanation of the portions of the constitution common to both will be omitted and only the different portions of the constitution will be explained below.

[0157]In the oxyfuel boiler 1 of the third embodiment of the present invention shown in FIGS. 8 and 9, compared with the oxyfuel boiler of the second embodiment shown in FIGS. 6 and 7, with respect that in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com