Beverage bottle filling plant with a beverage bottle labeling machine, and a cutting arrangement for a beverage bottle labeling machine

a beverage bottle and labeling machine technology, applied in the direction of liquid handling, packaging goods, transportation and packaging, etc., can solve the problems of increasing wear or deterioration of the blade elements, time-consuming, and difficult adjustment of the cutting gap, so as to achieve precise or substantially precise alignment, different hardnesses and/or wear resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

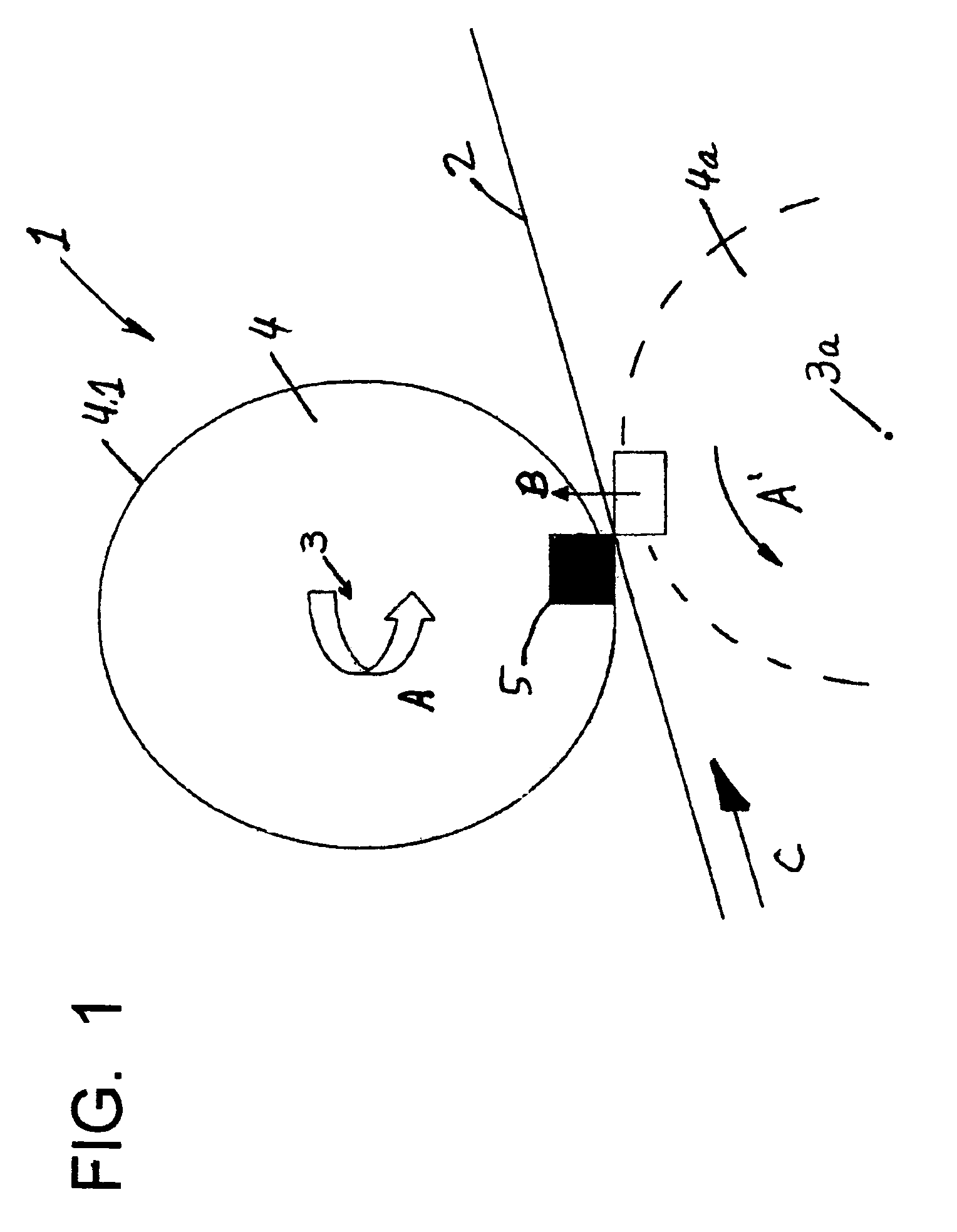

[0026]The reference 1 in FIG. 1 is given to a cutting device for cutting a strip-shaped or web-shaped flat material 2, for example a label material with a maximum thickness of 4 / 100 of a millimeter (0.25 mm) or less, i.e. for the separating of individual labels from the material 2.

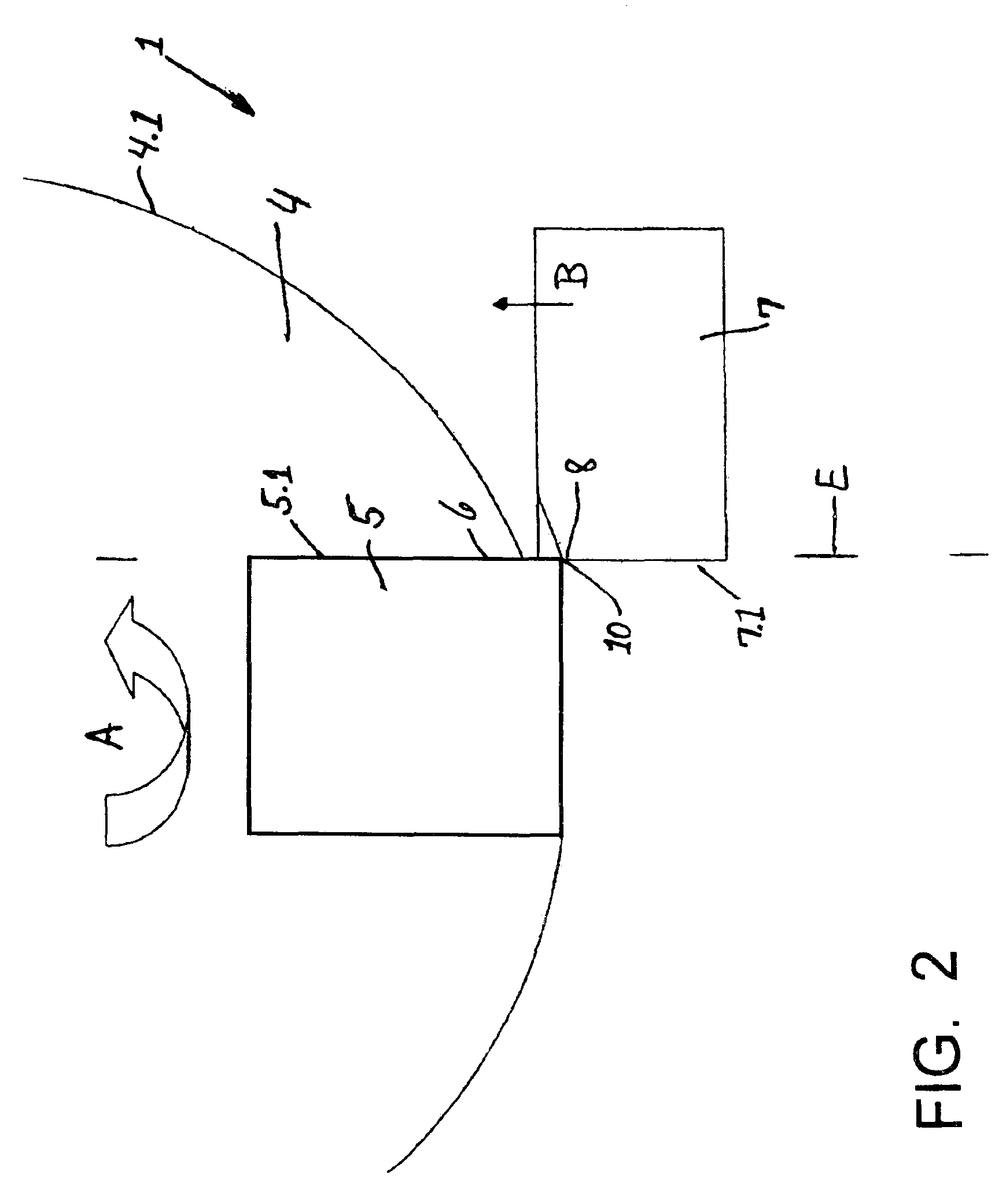

[0027]The cutting device 1 essentially comprises a machine element 4 that is driven in a rotating manner about a vertical or substantially vertical machine axis 3 in the direction of the arrow A, said machine element having, for example, a peripheral surface or outer surface 4.1 that surrounds the vertical or substantially vertical machine axis 3 in a circular cylindrical manner and being provided, for example, so as to be exchangeable and adjustable on the peripheral surface or outer surface 4.1 with at least one blade element 5, in such a manner that the blade element 5 forms a cutting edge 6 on a region protruding beyond the outer surface 4. In the case of the specific embodiment represented, the cuttin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com