Spooling arrangement for continuous composite sucker rod

a composite sucker rod and spooling technology, which is applied in the direction of web handling, drilling pipes, transportation and packaging, etc., can solve the problems of limiting the length of the rod that can be stored on the reel, presenting a time-consuming and labor-intensive process, and about 300 feet of rod length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

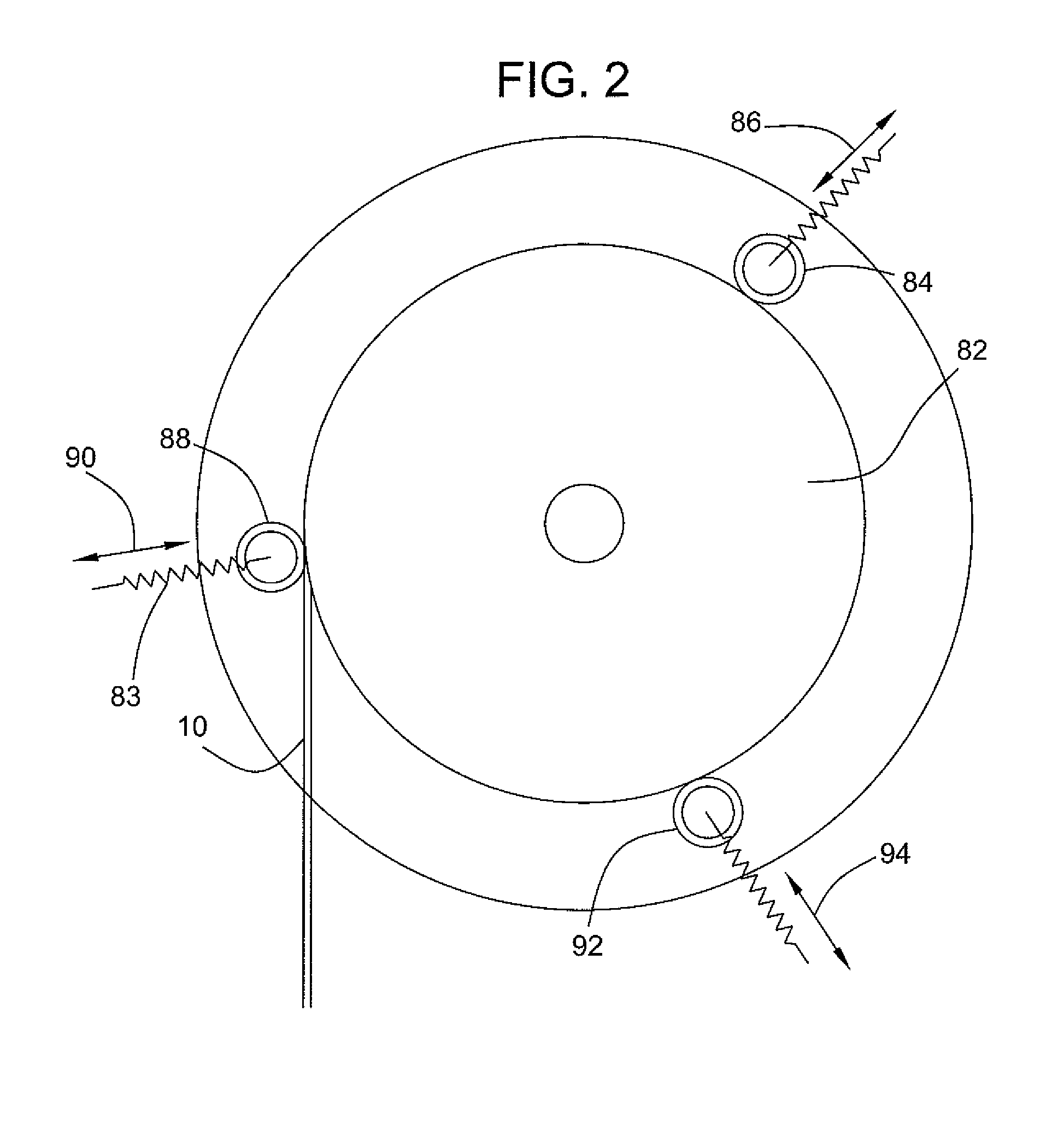

[0019]A continuous fiberglass rod 10 for use in a wellbore 30 is shown in FIG. 1. As used herein, “continuous” fiberglass rod means fiberglass rods that are continuous, i.e. either without interconnections or with very few interconnections, from near the surface to near the bottom of the well 30. The continuous fiberglass rod 10 connects between a pump jack 12 and a down-hole pump 36. In the illustrated embodiment, a coupling 28 is shown connected along the length of the rod 10.

[0020]Continuous composite fiberglass rod 10 may be reciprocated utilizing the pump jack 12. A typical pump jack may comprise a head 20, a beam 16, and a counterweight 18 pivotally mounted to support a frame 14. A pump jack motor 21 may be utilized to pivotally move a beam 16, and a connector 22 may be utilized to connect the head 20 to a fiberglass polished rod 24. The polished rod 24 can extend through a seal 26, which may comprise a pack-off or other sealing mechanism. The connector 28 may be utilized to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com