Hydraulic Control Arrangement for the Screed of a Road Finisher

a control arrangement and hydraulic technology, applied in the direction of fluid couplings, roads, roads, etc., can solve the problems of affecting the uniform laying of road tops, and achieve the effect of improving laying quality and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

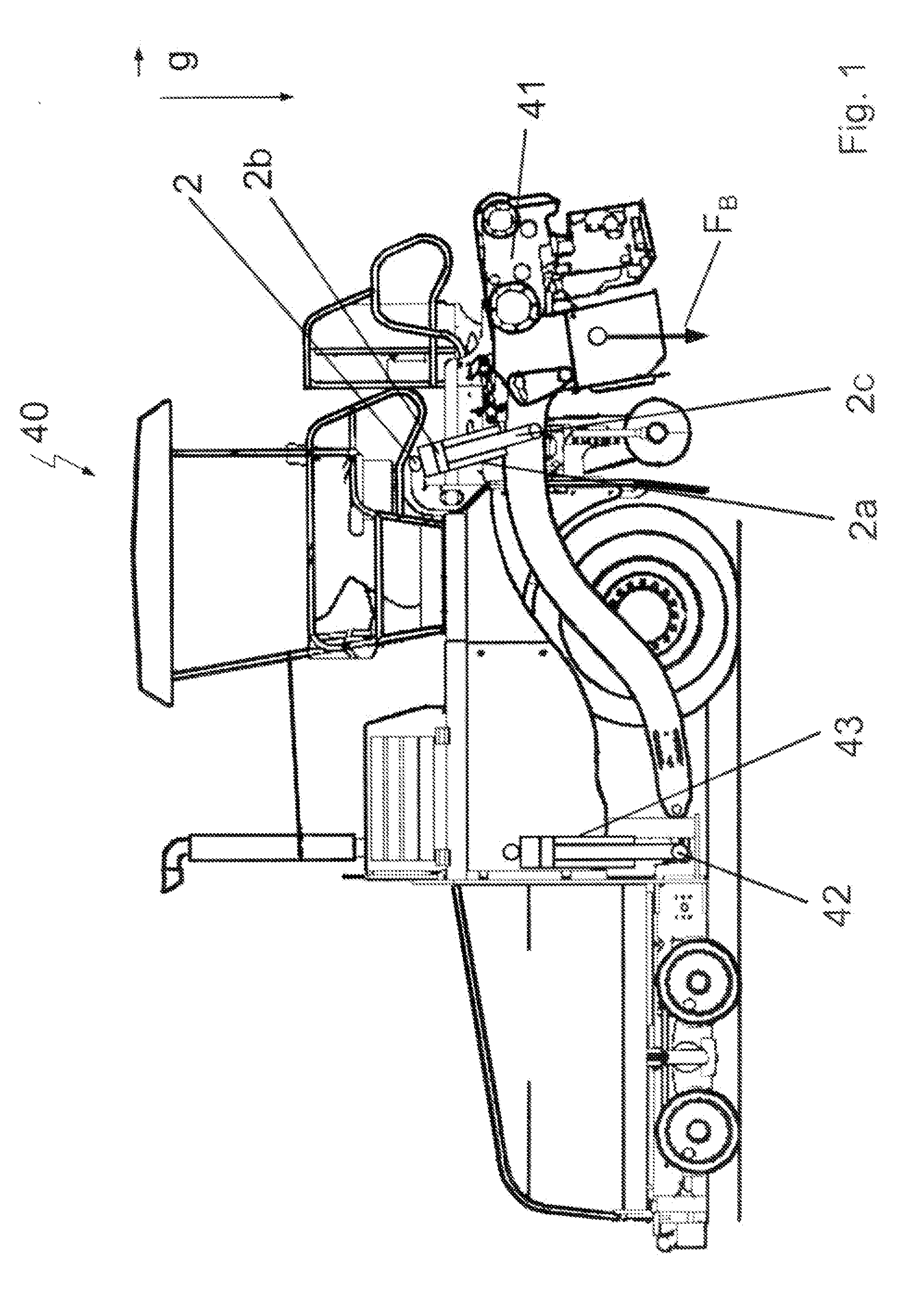

[0031]FIG. 1 is a side view of a road finisher 40 according to the invention. A screed 41 is articulated to the road finisher 40 at the point 42 and can be raised, lowered and held in any desired position with the aid of a double-acting actuating cylinder 2. The articulation point 42 itself is vertically adjustable via a leveling cylinder 43 in order to define the setting angle of the screed 41. This setting angle determines in combination with the speed of travel primarily the laying thickness. The actuating cylinder 2 is articulated on the piston side, i.e. with the cylinder housing 2a, to the chassis of the road finisher 40. On the piston-rod side, the actuating cylinder 2 is articulated to the screed 41. The screed 41 generates, on account of its dead weight, the weight force FB which is directed perpendicularly downward. In the position shown, the road finisher 40 is en route to the site of use, so that no force is directly exerted by the screed 41 onto the substrate.

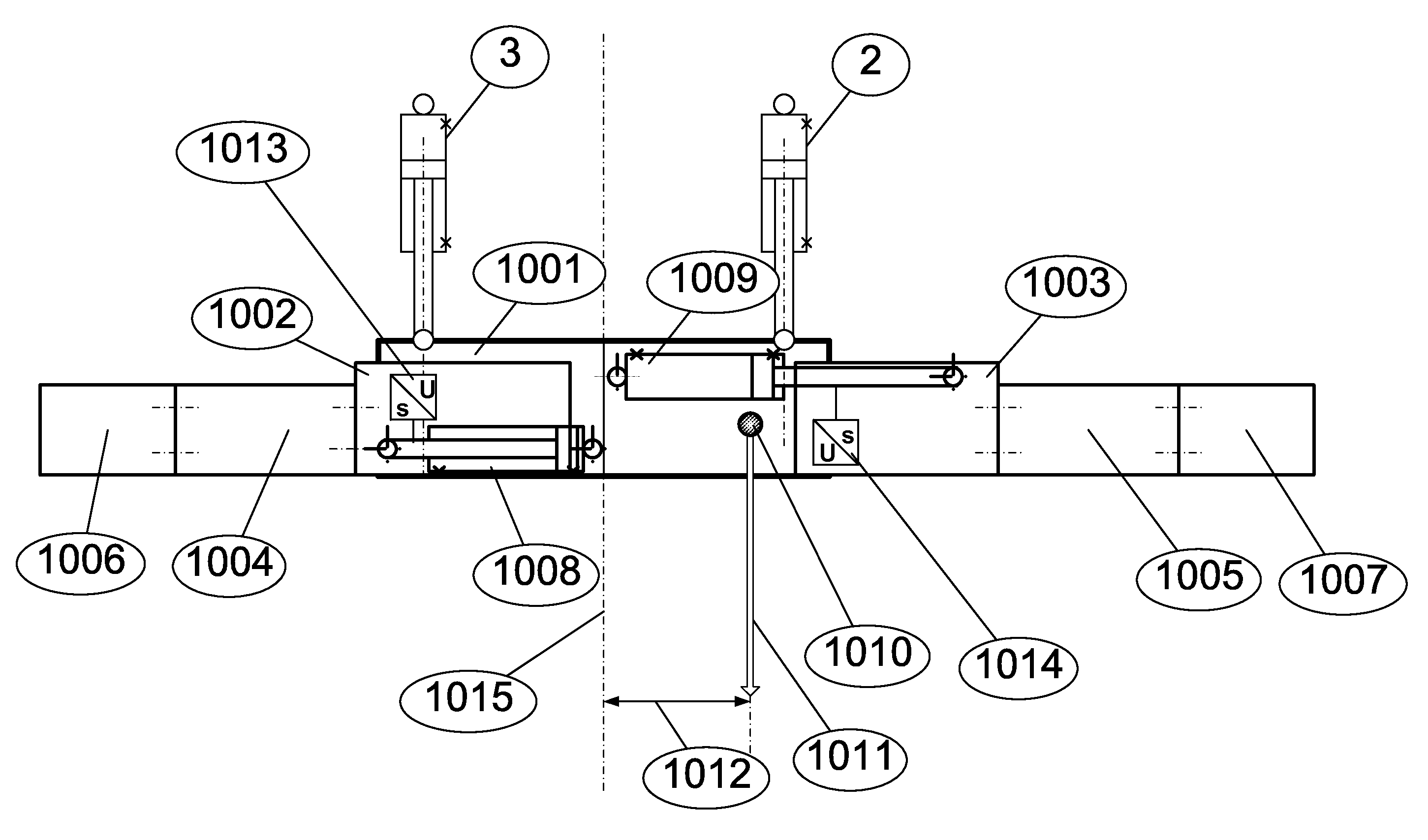

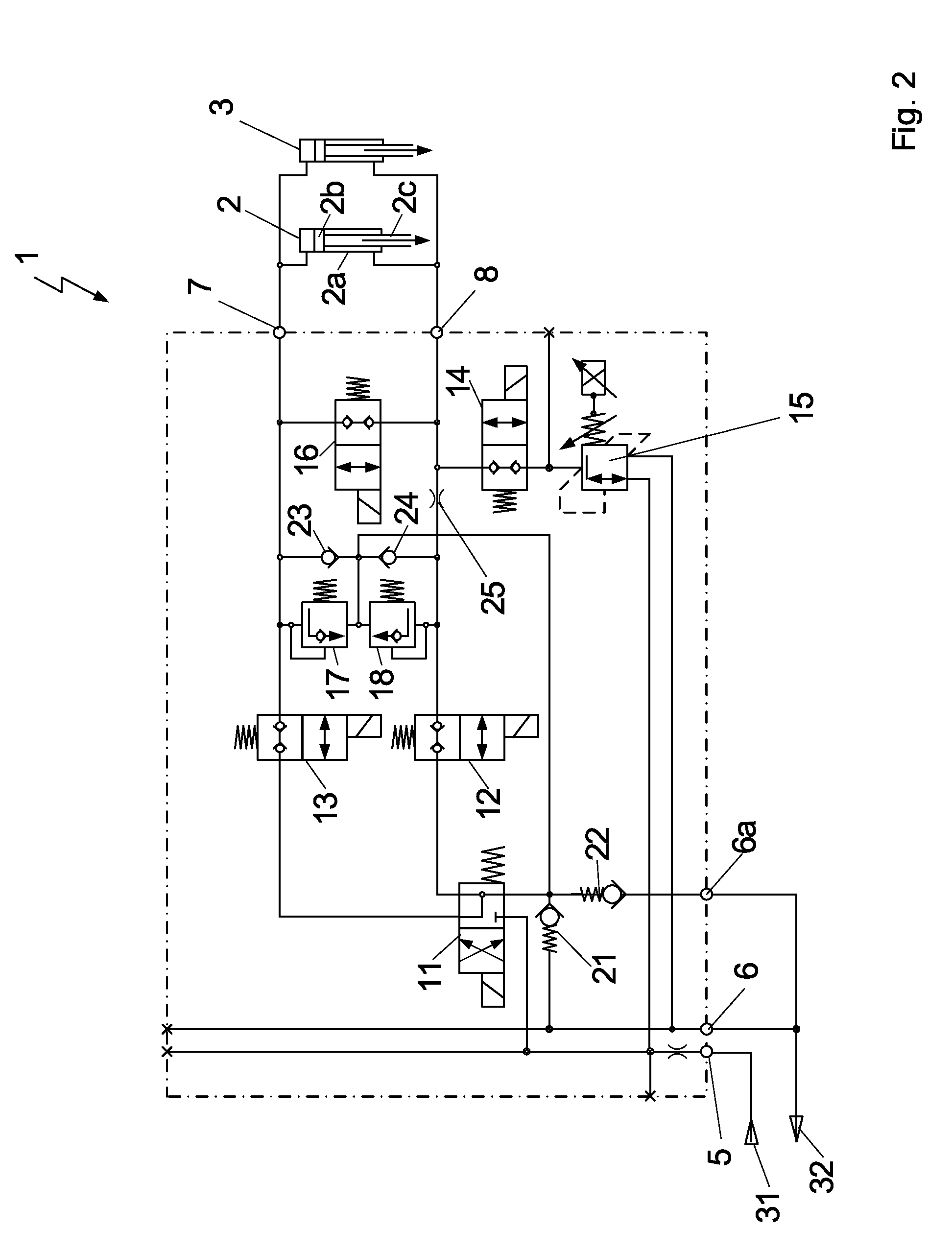

[0032]FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com