Sink With Storage Rack Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

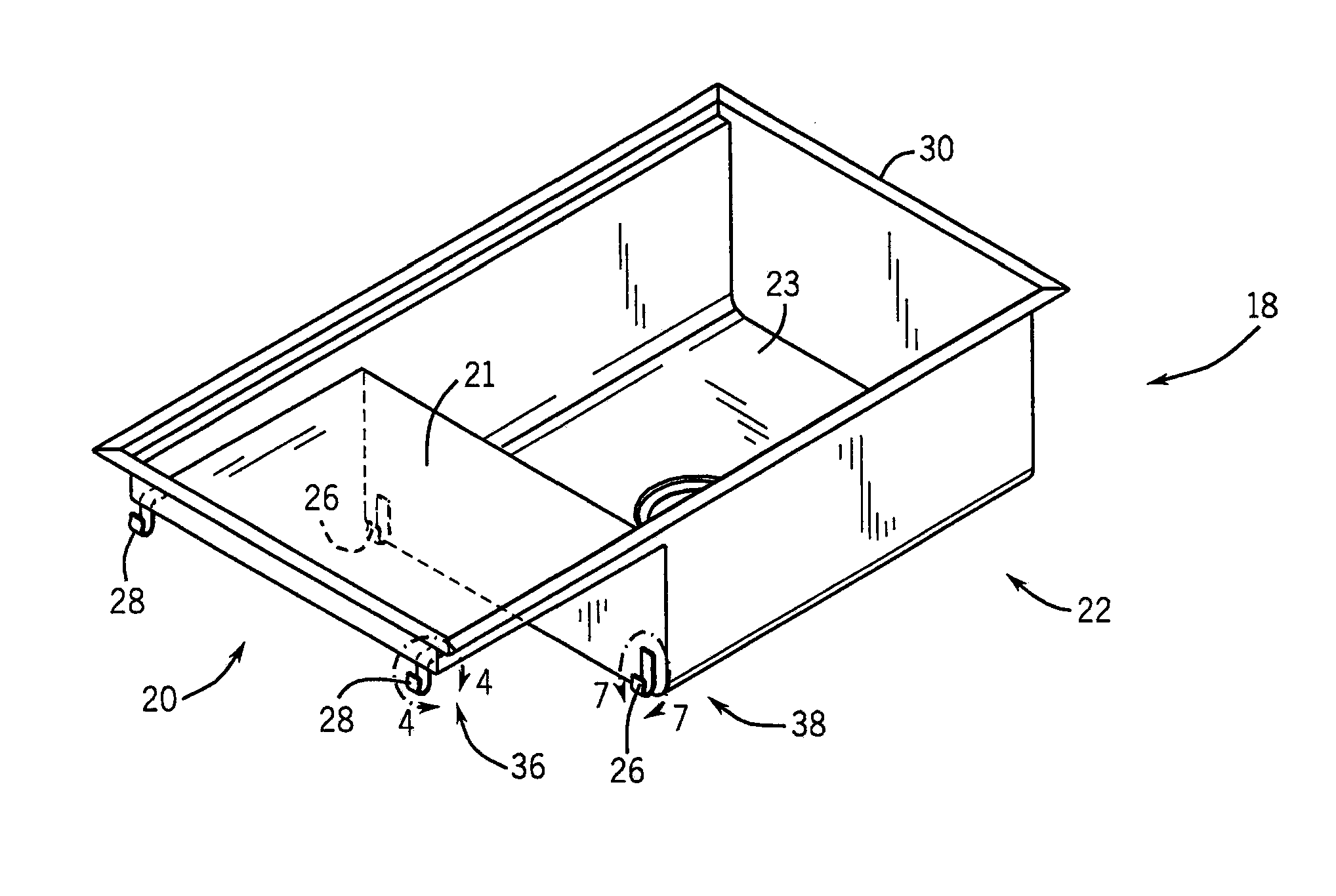

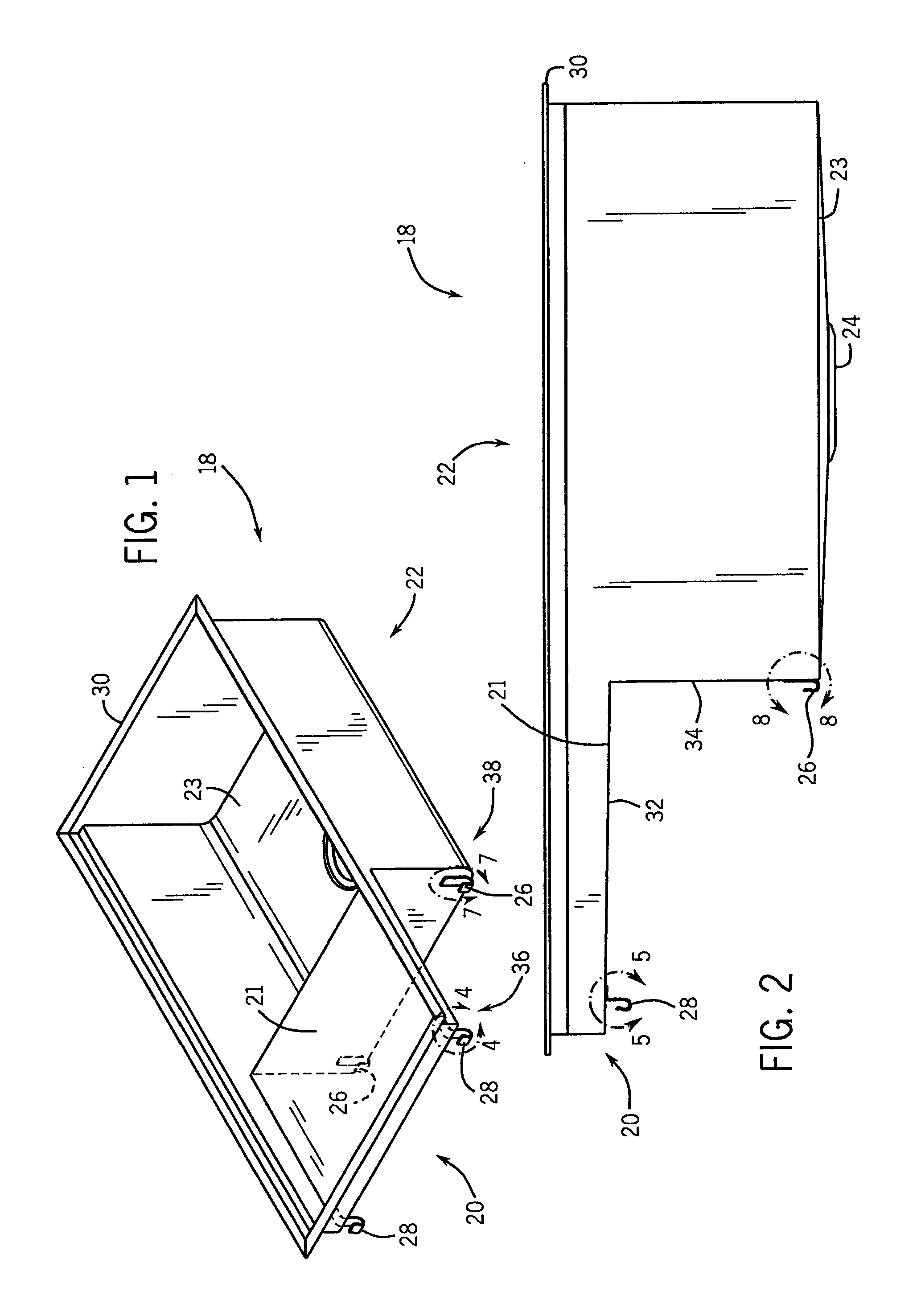

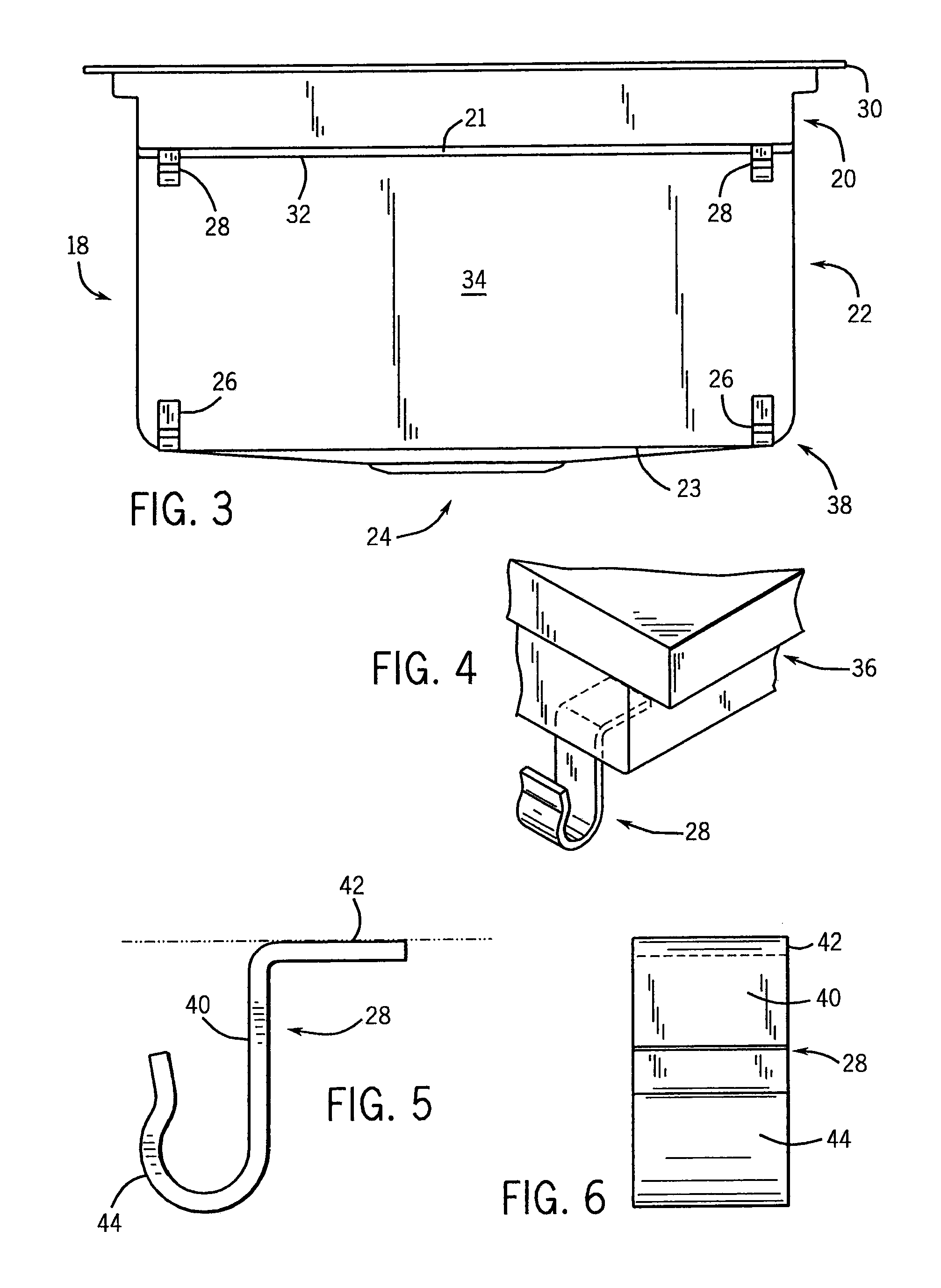

[0036]Referring first to FIGS. 1-3, there is shown a sink 18 of the present invention which contains a sink basin 22 that is substantially rectangular in shape. The sink basin has a bottom surface 23 containing the usual drainage hole 24 for draining liquids and other materials held in the sink basin 23. A garbage disposal (not shown) may be installed underneath the drainage hole 24 to grind up any waste materials held in the sink basin 22.

[0037]A work / drain area 20 is integral to the sink basin 22 and extends (in this embodiment) to the left of the sink basin 22. The surface of the work area 21 is substantially flat and is substantially higher than the bottom surface of the sink basin 23, facilitating the easy transfer of liquids and waste materials from the work area 20 to the sink basin 22.

[0038]The sink 18 further has four spring clips 26, 28 mounted on the assembly 18. Two of the spring clips are side mounted spring clips 26, which are mounted to the left side exterior surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com