Group iii nitride semiconductor device and light-emitting device using the same

a technology of nitride and semiconductors, applied in the direction of semiconductor devices, basic electric elements, electrical appliances, etc., can solve the problems of large amount of crystal defects, high dissociation pressure, and failure to retain single crystals, etc., to achieve high reverse withstand voltage and improve crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

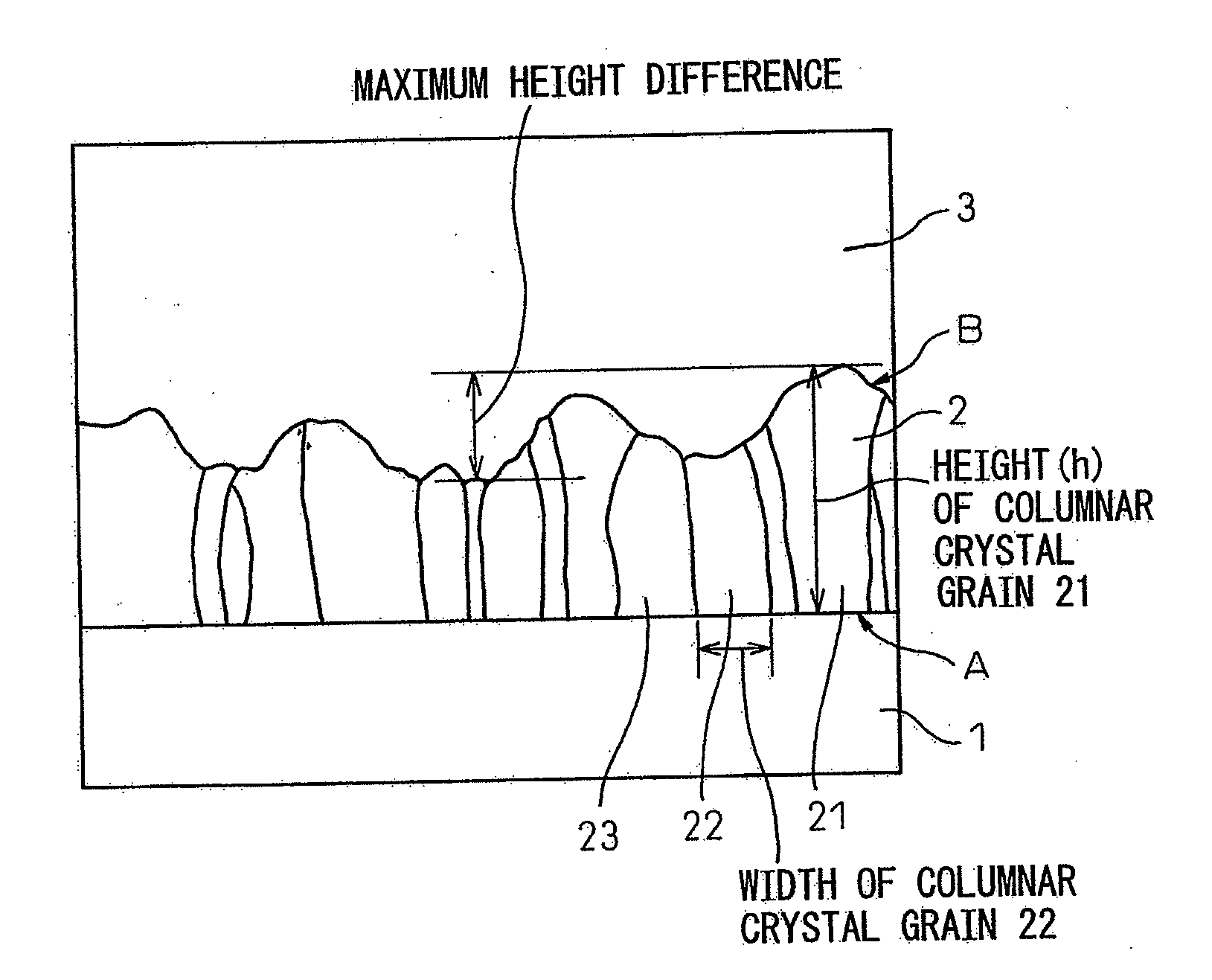

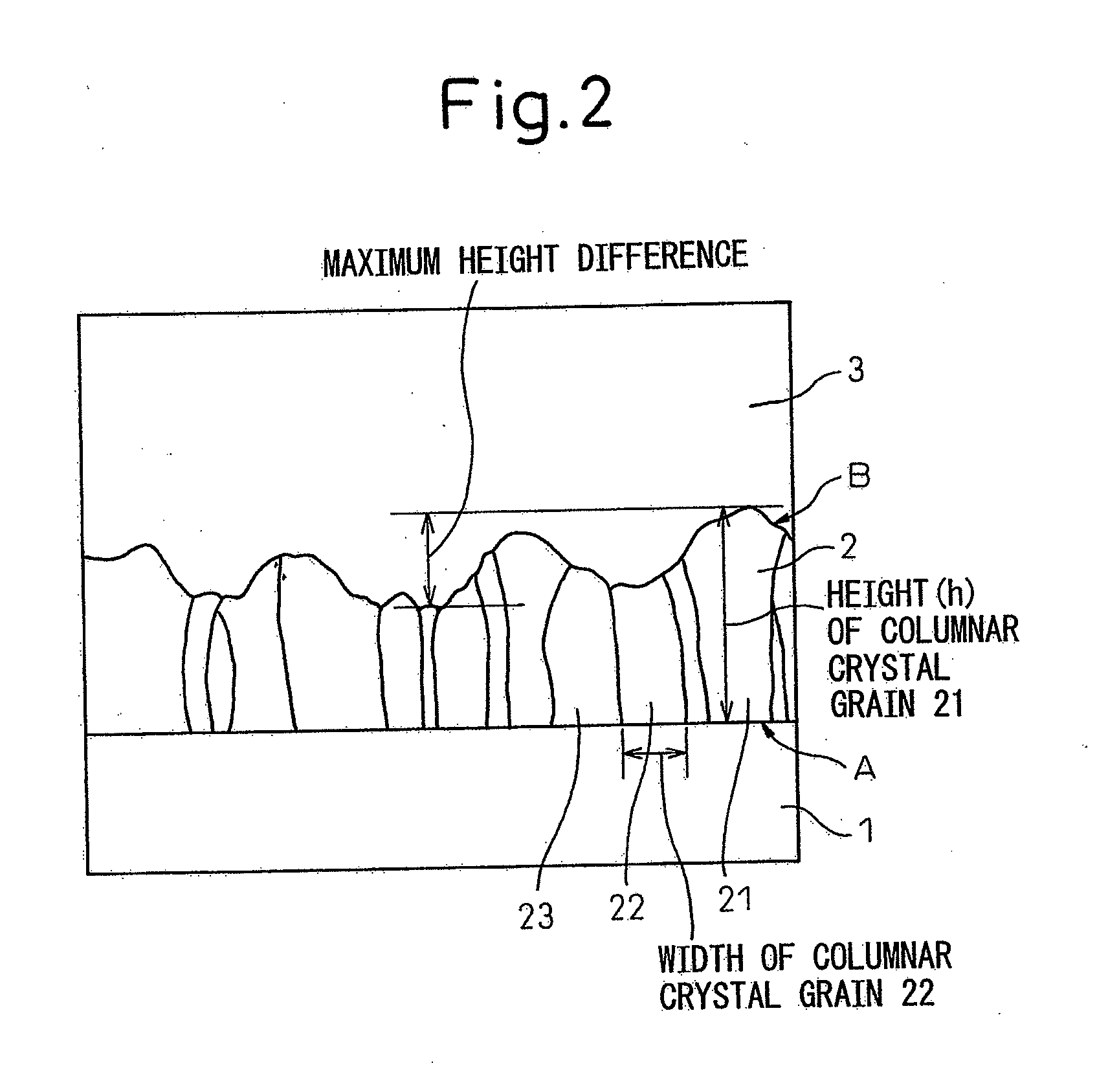

Method used

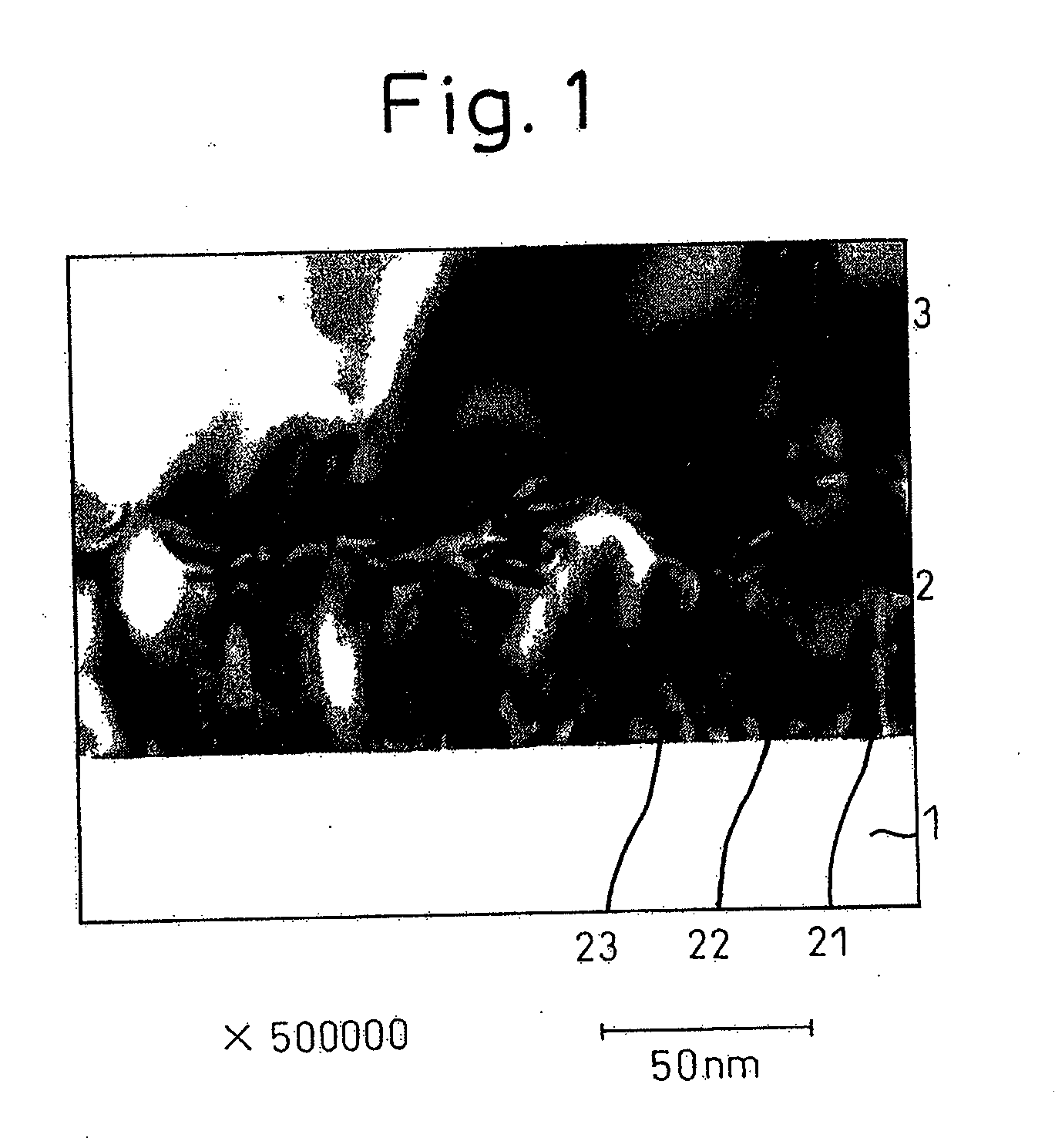

Image

Examples

example

[0045]FIG. 5 is a schematic representation showing the Group III nitride semiconductor light-emitting device of the present invention produced in the present Example. Reference numeral 1 denotes a substrate composed of sapphire. Semiconductor layers were grown along the crystal plane orientation of the substrate. A first layer 2 composed of Al0.08Ga0.92N doped with Si (5×1018 atoms / cm3) was formed on the substrate. A second layer 3 composed of an undoped GaN single crystal layer, and an n-type GaN single crystal layer 4 doped with Si (1×1018 atoms / cm3) were successively formed on the first layer 2. A light-emitting layer 6 was formed, via a Ga0.98In0.02N layer 5, on the Si-doped GaN single crystal layer 4. The Ga0.98In0.02N layer 5 is provided between the Si-doped GaN layer 4 and the light-emitting layer 6 for preventing propagation of crystal defects from the Si-doped GaN layer 4.

[0046]The light-emitting layer 6 has a structure including a plurality of stacked layer units, each inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com