Addressable matrices/cluster blanks for dental cad/cam systems and optimization thereof

a technology of cluster blanks and matrixes, applied in dental surgery, dental crowns, medical science, etc., can solve the problems of reducing the efficiency of the facility operating a cad/cam system, forming blanks b>100/b>, and lacking material selection to be competitive in a supersaturated and fast environment, so as to maximize the impact of cluster blanks on system efficiency, minimize waste and material removal, maximum interchangeability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

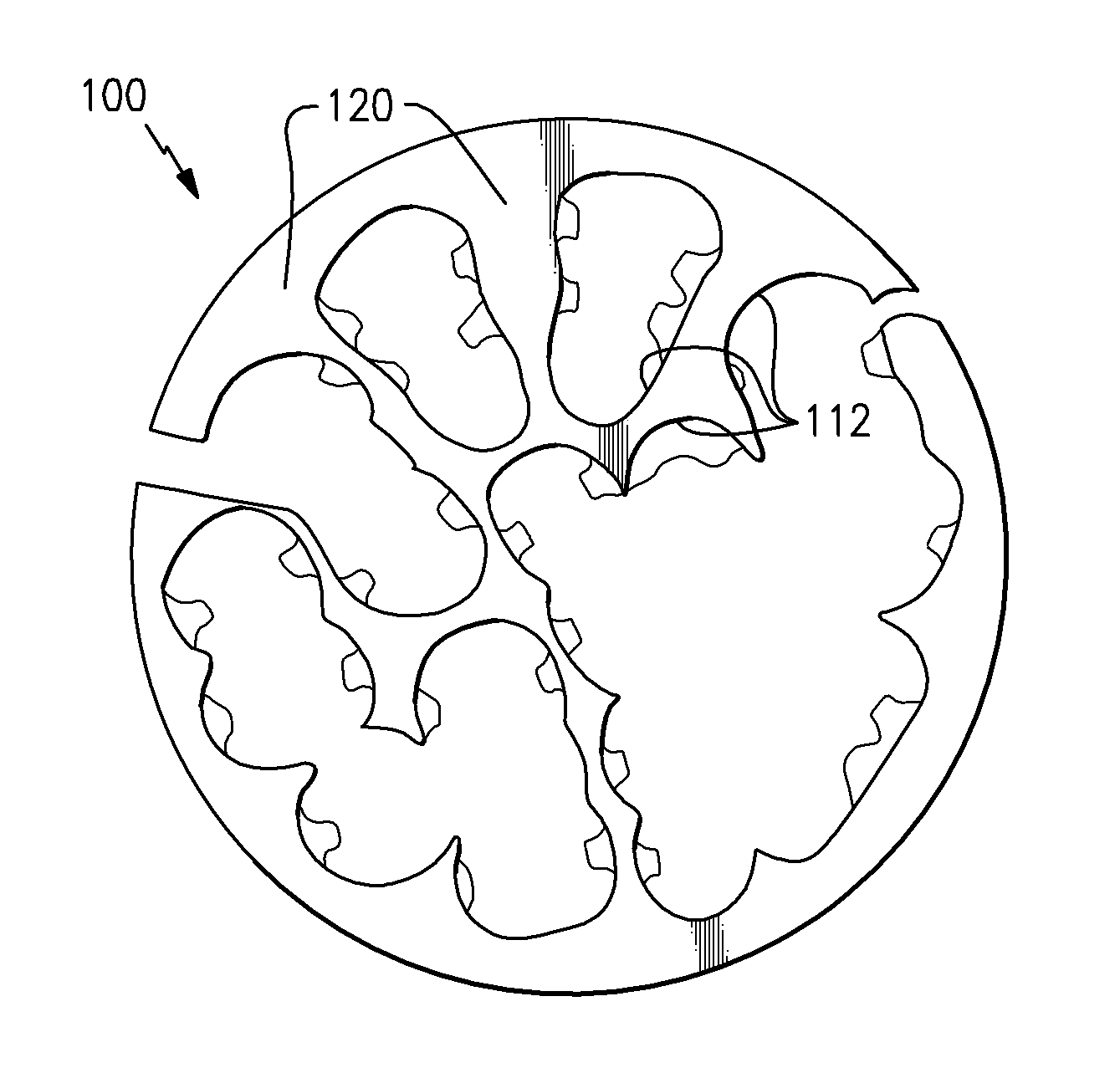

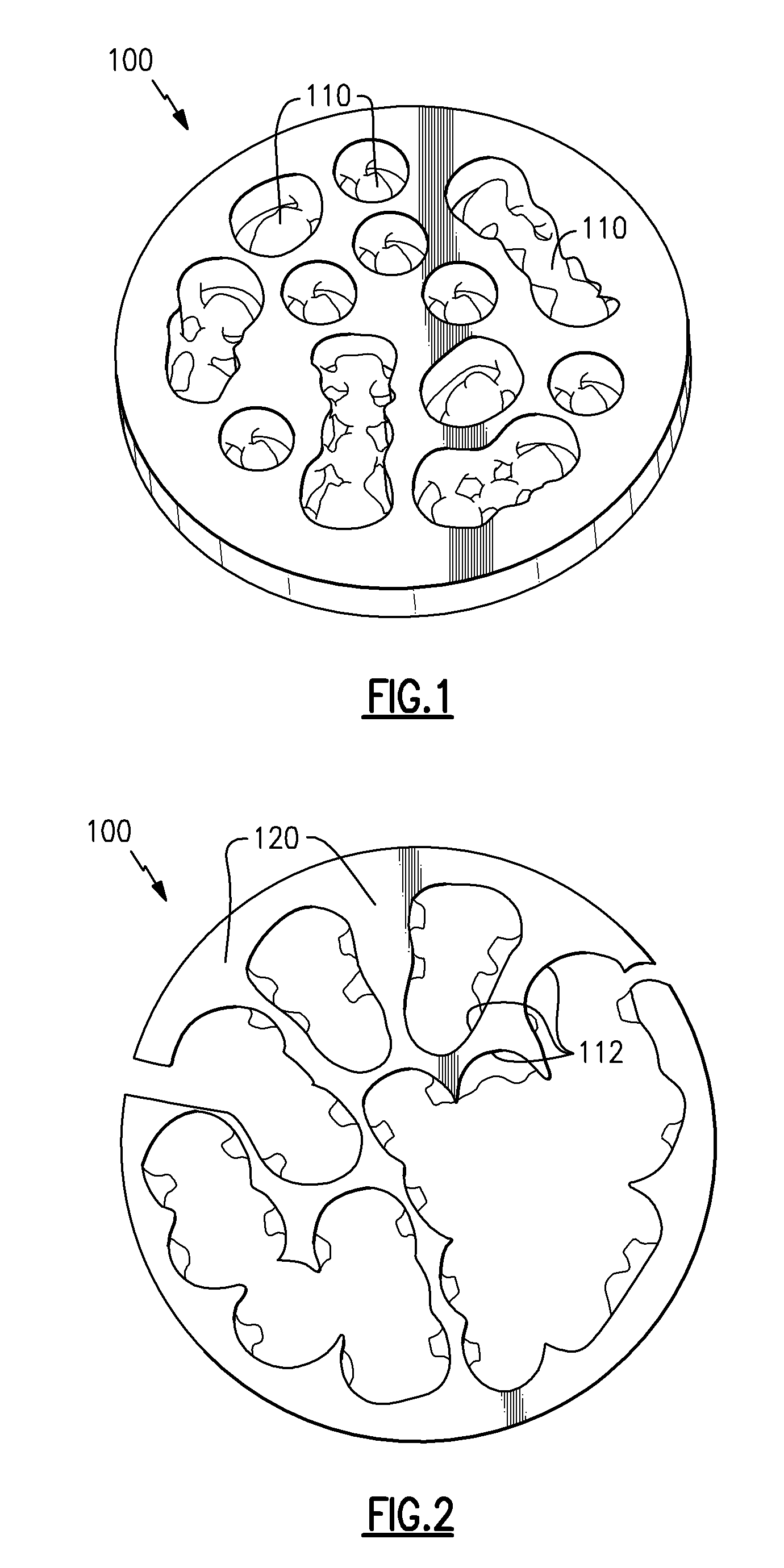

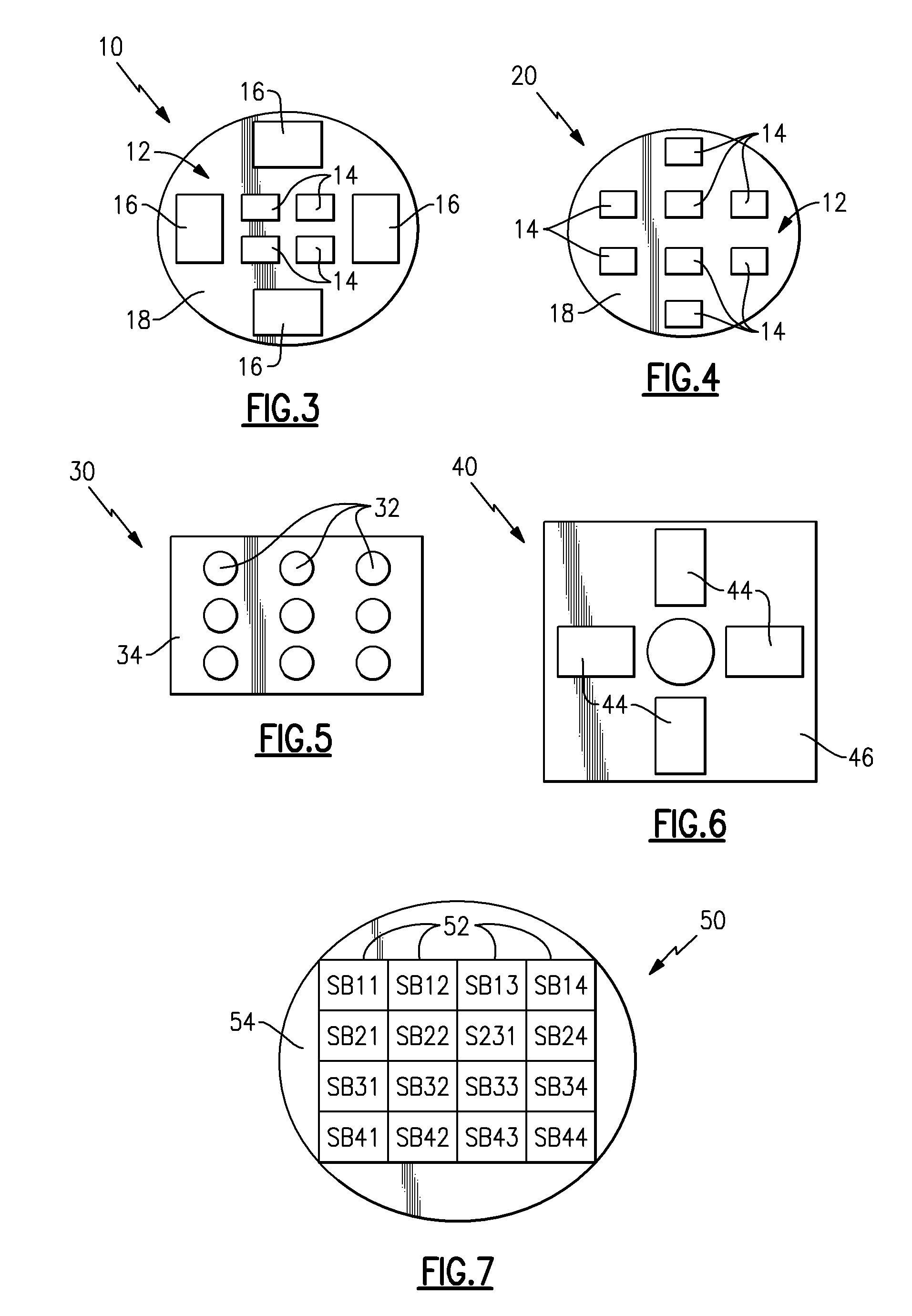

[0065]According to one optional aspect of the present invention, various cluster blanks are formed from individual blanks using prefabricated or custom-made frameworks to enable the use of individual blanks in the maximum possible number of systems. Hereafter individual blanks being assembled into a cluster blank will be termed sub-blanks. A cluster blank can comprise sub-blanks of identical size and shade, or different shades, sizes and / or types of sub-blanks. For example, a cluster blank can comprise various sizes and shades of the same sub-blank type and also a variety of different types of sub-blanks from one or different manufacturers can be assembled on the same framework to make a “hybrid” cluster blank. For example, e.max CAD MO and / or LT blanks (Ivoclar) also known as “blue blocks” can potentially be processed by any robust CAD / CAM system utilizing wet-milling process and having software capable of designing full-contour restorations. An example of such a system capable of,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| structures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com