Tilt-Wall Panel

a technology of tilting wall and sidewall, which is applied in the direction of girders, building repairs, walls, etc., can solve the problems of difficult to punch out l-shaped tabs from the sidewall, high cost of insulation, and insufficient engagement of surrounding concrete, etc., to achieve easy and less expensive construction, improve insulation, and lighten weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

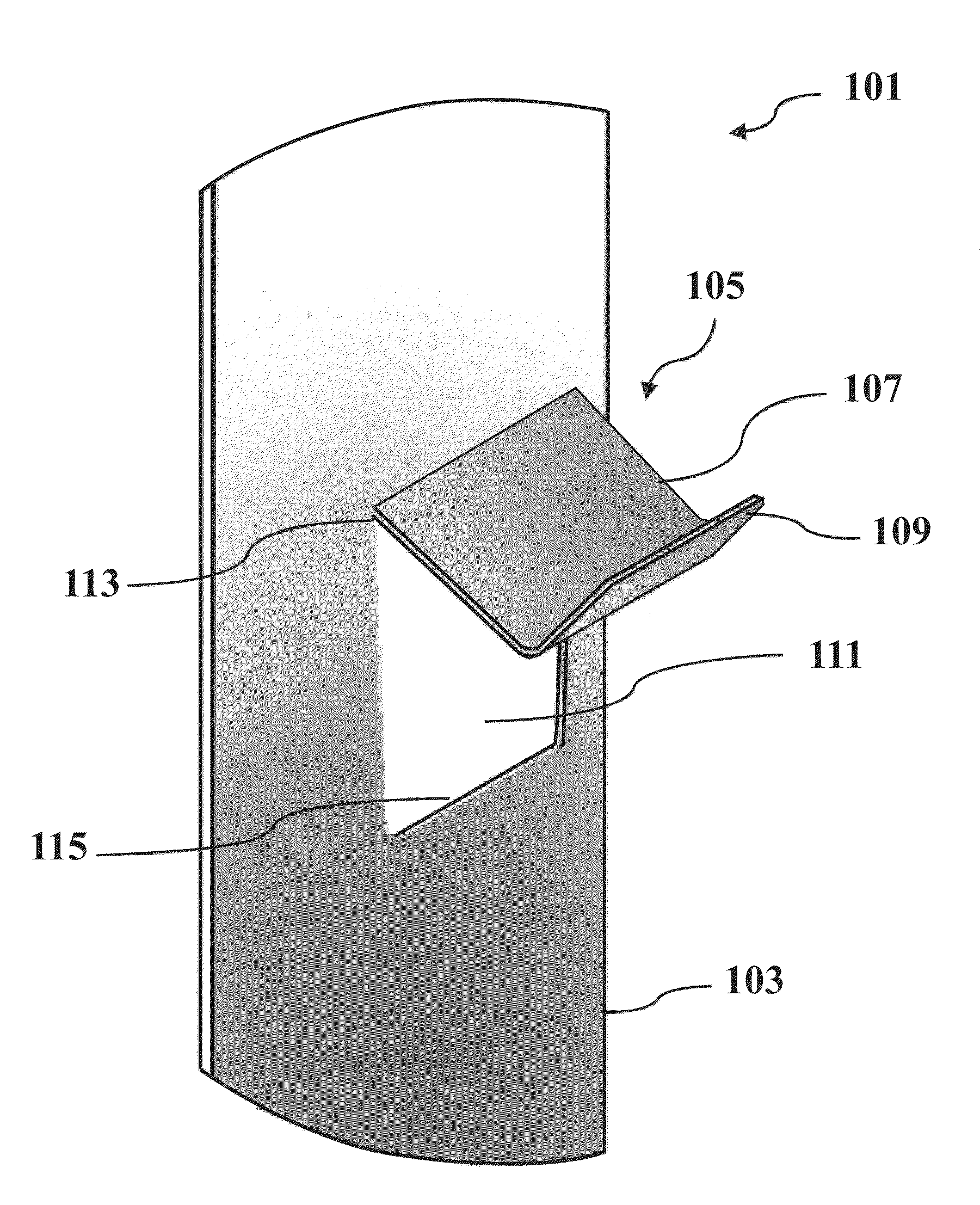

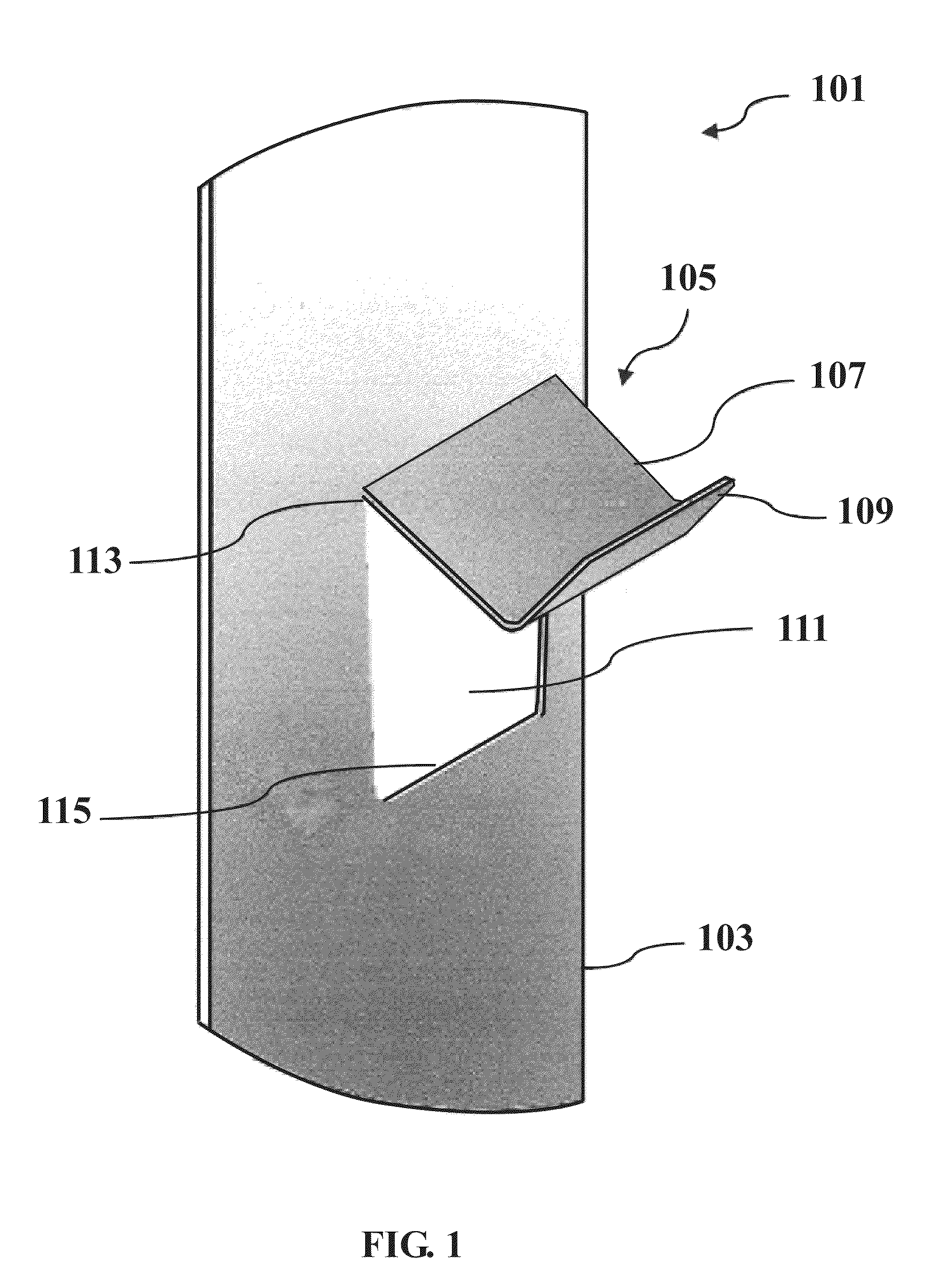

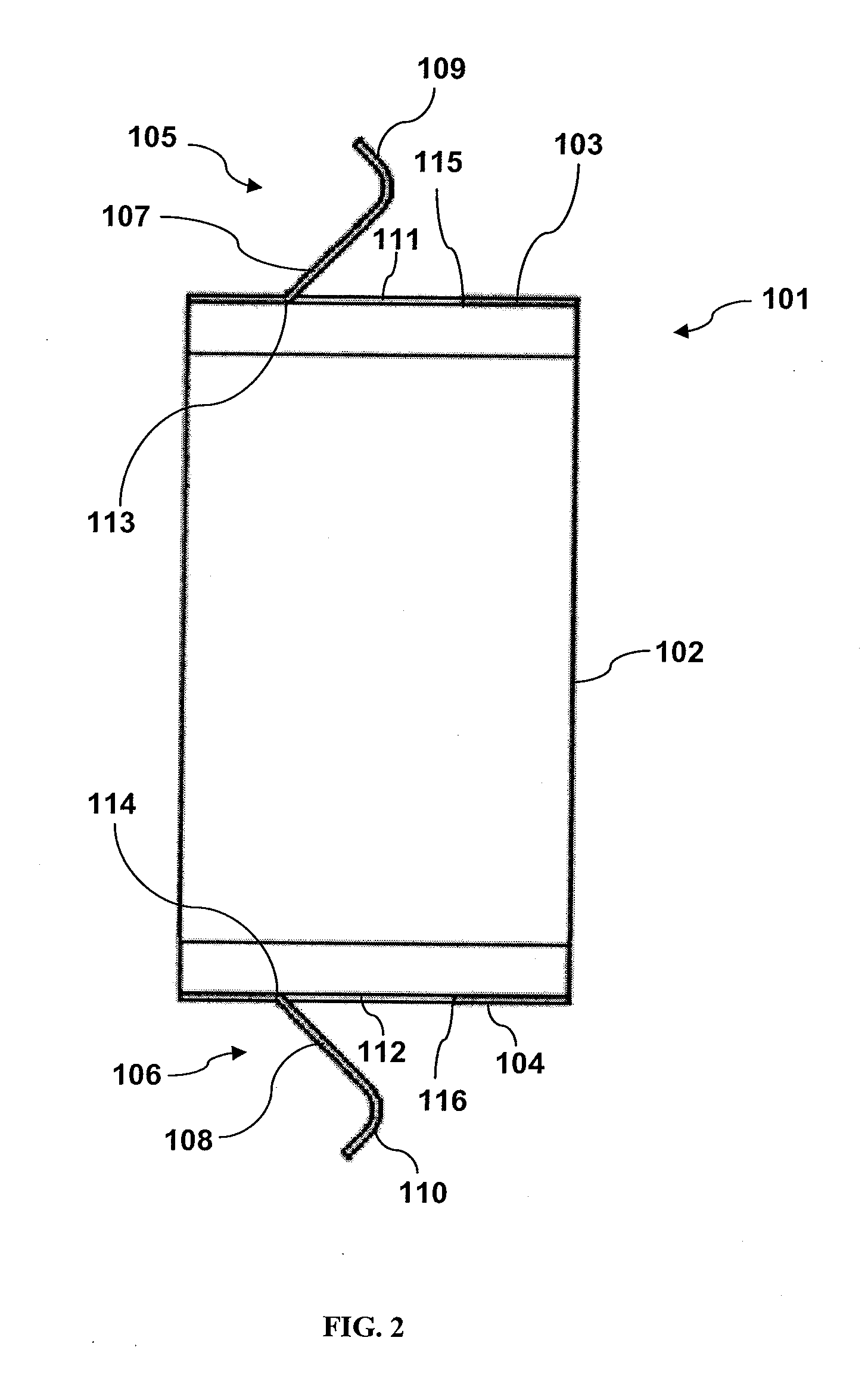

[0038]One embodiment of the structural studs used in the present tilt-wall panels is partially shown in FIGS. 1-4. The structural stud comprises a stud 101 having a baseplate 102, sidewalls 103 and 104 connected to the baseplate 102, and tabs 105 and 106 punched out of the sidewalls. The tabs 105 and 106 comprise tab legs 107 and 108 that are substantially planar and are connected to the sidewalls 103 and 104 at one end of tab legs 107 and 108. The tab legs 107 and 108 project outwardly from the sidewalls 103 and 104 at an angle of less than ninety degrees to the sidewalls 103 and 104. Having the tab legs 107 and 108 project outwardly at an angle of less than ninety degrees results in improved adhesion between the structural stud and the surrounding concrete. The tabs 105 and 106 also comprise tab feet 109 and 110 extending from the tab legs 107 and 108 and curving away from holes 111 and 112 in the sidewalls 103 and 104 created by the tabs 105 and 106 punched out of the sidewalls 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com