Steel plate for linepipe having ultra-high strength and excellent low temperature toughness and manufacturing method of the same

a technology of steel plate and linepipe, which is applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of excessive reheating temperature, excessive cooling finish temperature, and high cooling rate, and achieve excellent low temperature toughness and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Exemplary embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

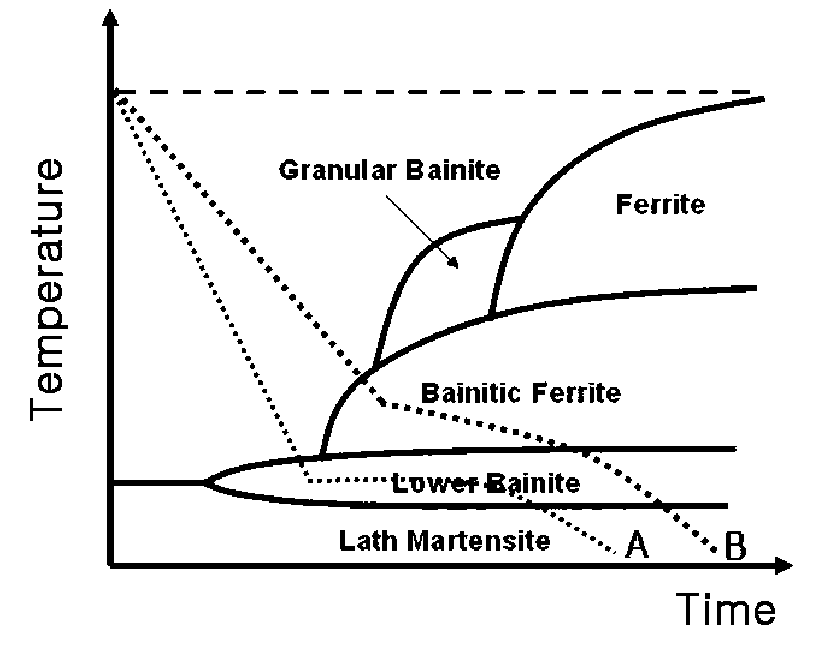

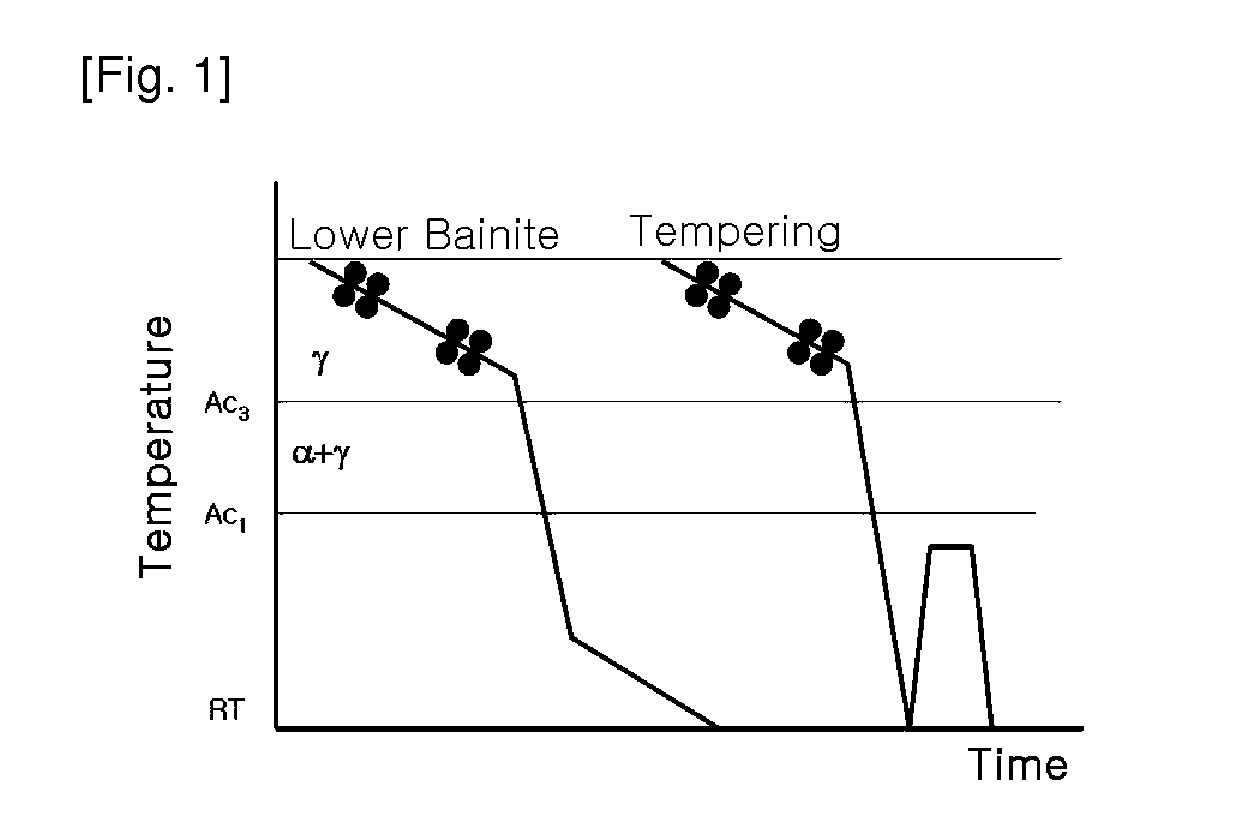

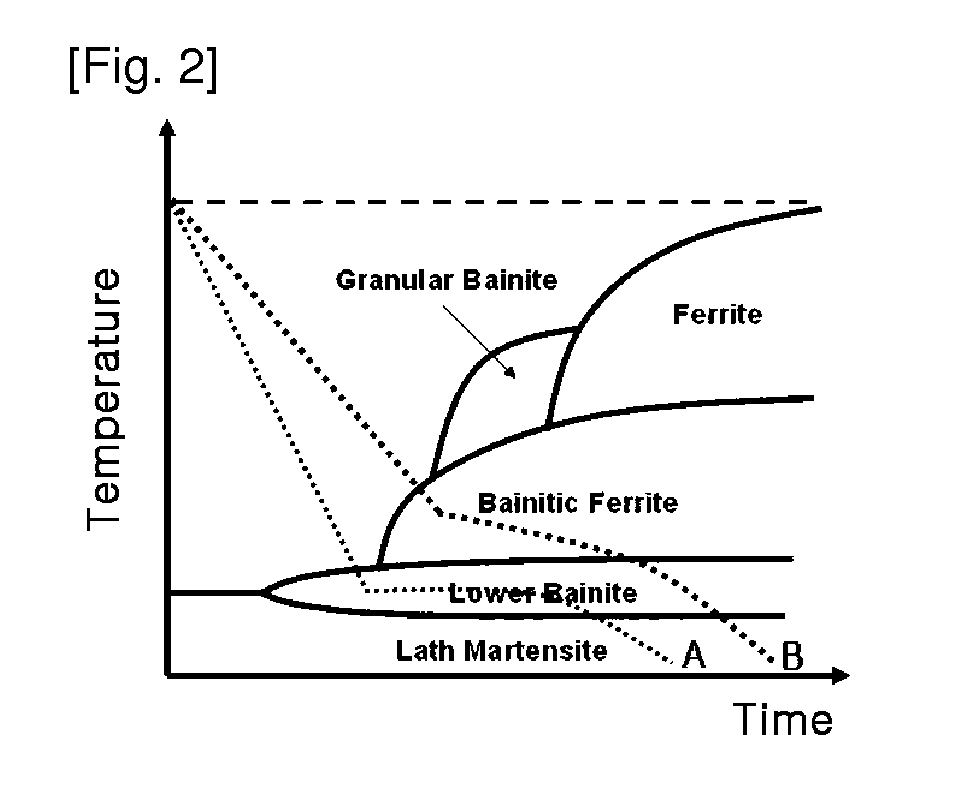

[0035]Through the extensive and intensive investigation for the problems of the conventional techniques, inventors of the present invention have found the following facts: with adding smaller Mo than existing invent, which has been added to steel for increasing the strength of a steel plate, the steel plate can exhibit sufficient strength even without forming lower bainite or lath martensite as is formed in the existing invent for ultra-high strength steel, and at the same time, the steel plate can also have good toughness by making the fine austenite grain size with controlling the rolling condition and with other kinds of microstructure instead of very hard microstructure, such as lower bainite or lath martensite. The present invention is made based on these findings.

[0036]Specifically, in a steel plate according to the invention, the content of Mo is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com