Caliper mounting arrangement

a mounting arrangement and caliper technology, applied in the direction of axially engaging brakes, brake types, braking elements, etc., can solve the problems of rotor cracking, bolts to bend, thermal distortion of rotors, etc., and achieve the effect of convenient access and maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

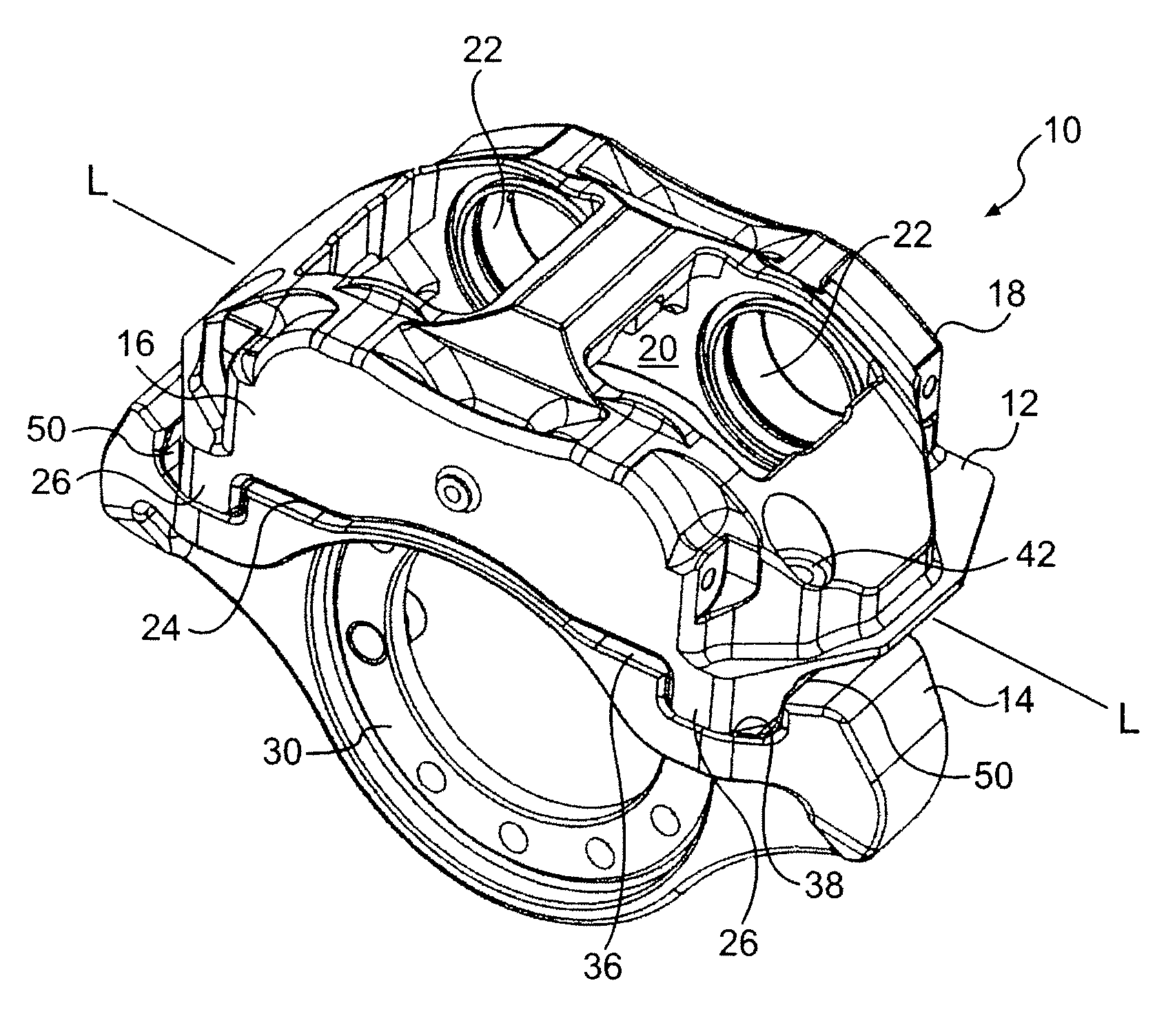

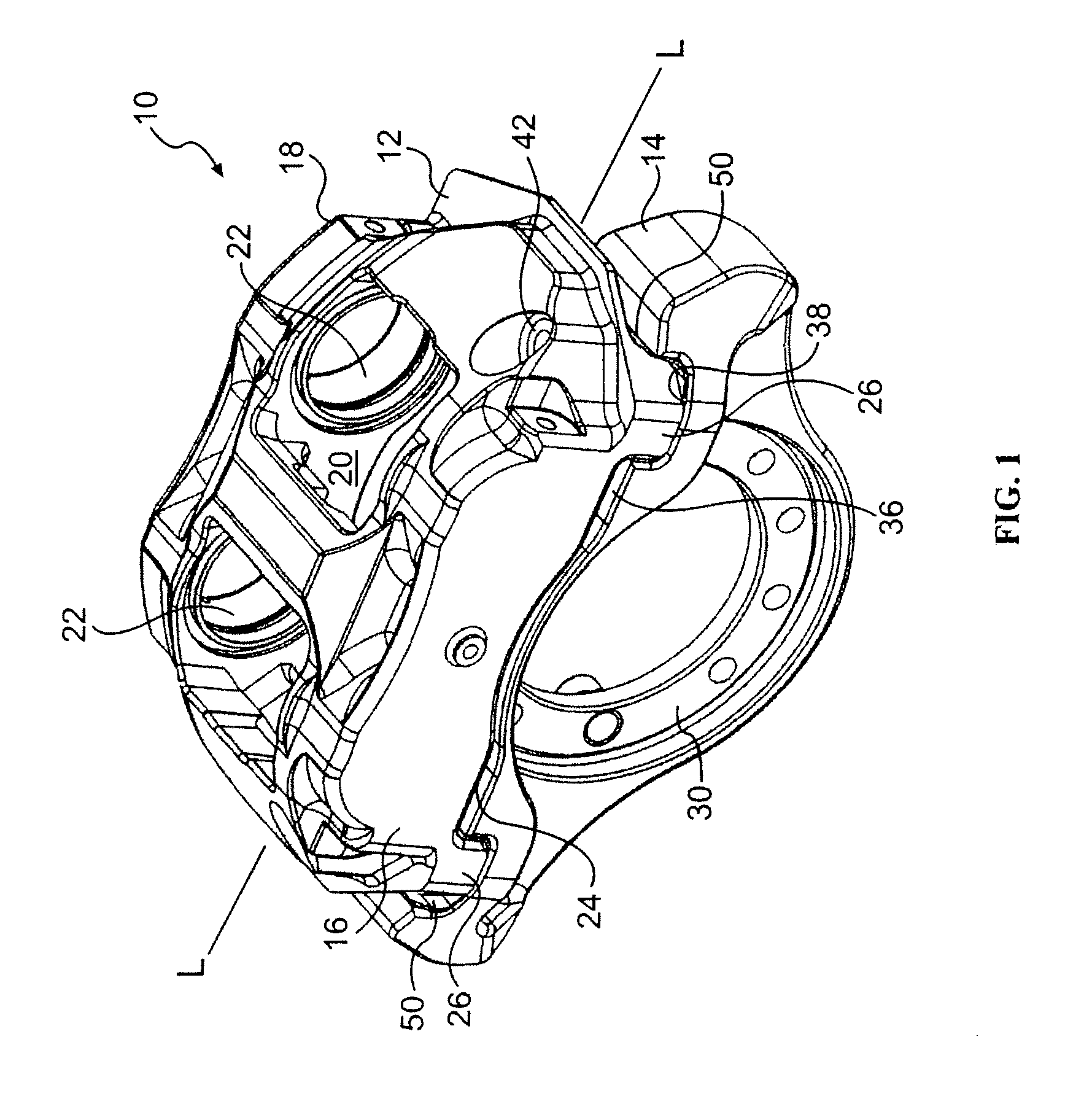

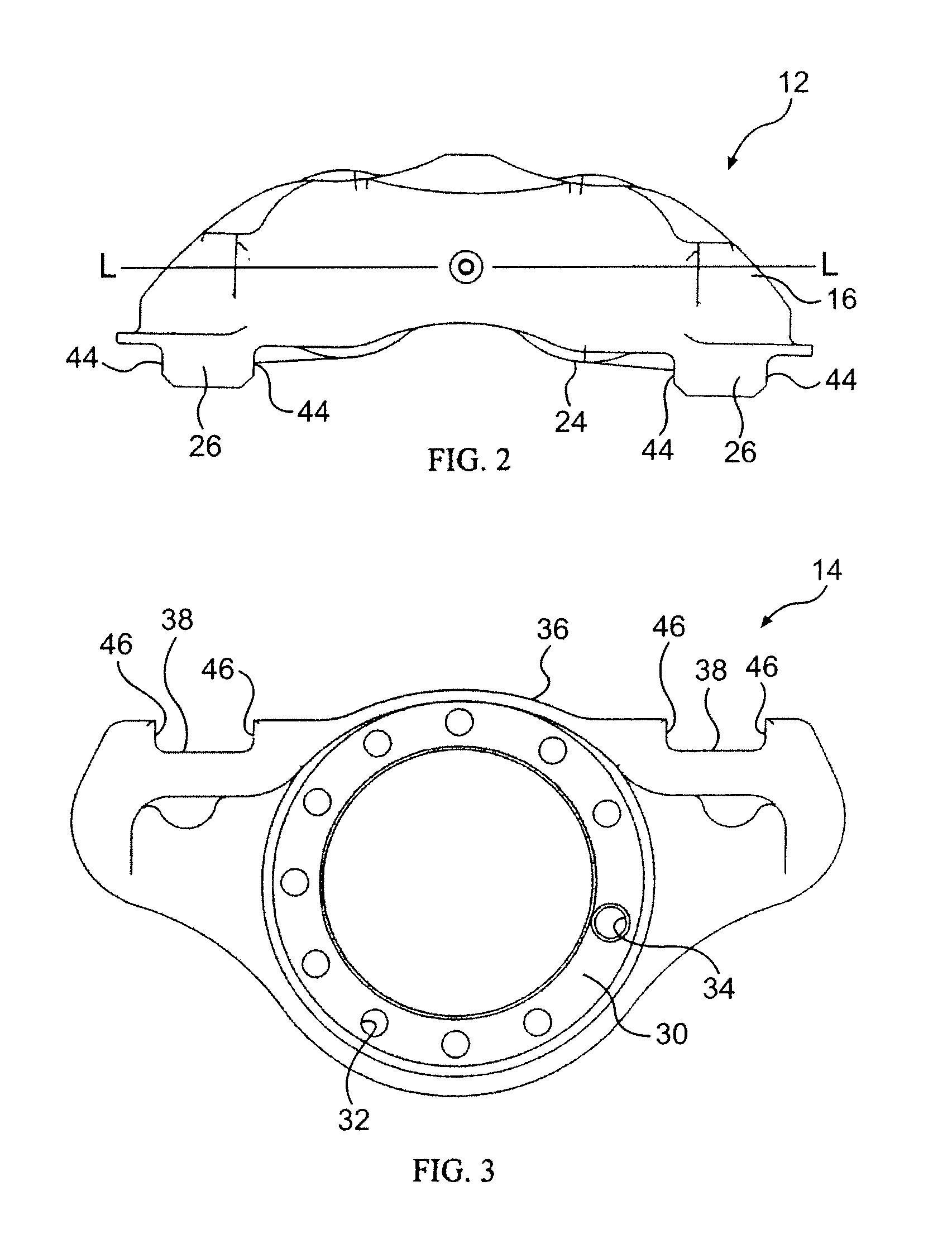

[0034]This invention is described for use in a vehicular disc brake system. The caliper assembly described below is used for illustrative purposes only and it will be understood that this invention may be used in various types of braking systems and with any rotor. The invention can be used in conventional automobiles, racing vehicles, motorcycles, medium duty vehicles, and heavy duty trucks. As the invention provides an increased ability to withstand high torque applications, it is well suited for vehicles having a gross vehicle weight (GVW) of 11,000 pounds or more, such as in trucks, ambulances, and buses. In the description below, the brake pads, rotor, and fixed mounting member are not shown as they are conventionally known.

[0035]Referring to FIGS. 15-17, conventional caliper assemblies use a bolted connection between the caliper body 100 and the torque plate. The caliper body 100 includes two opposed side portions 102 and 104 that extend on either side of a longitudinal axis L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com