Solar Heat Powered System comprising at least one solar collector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

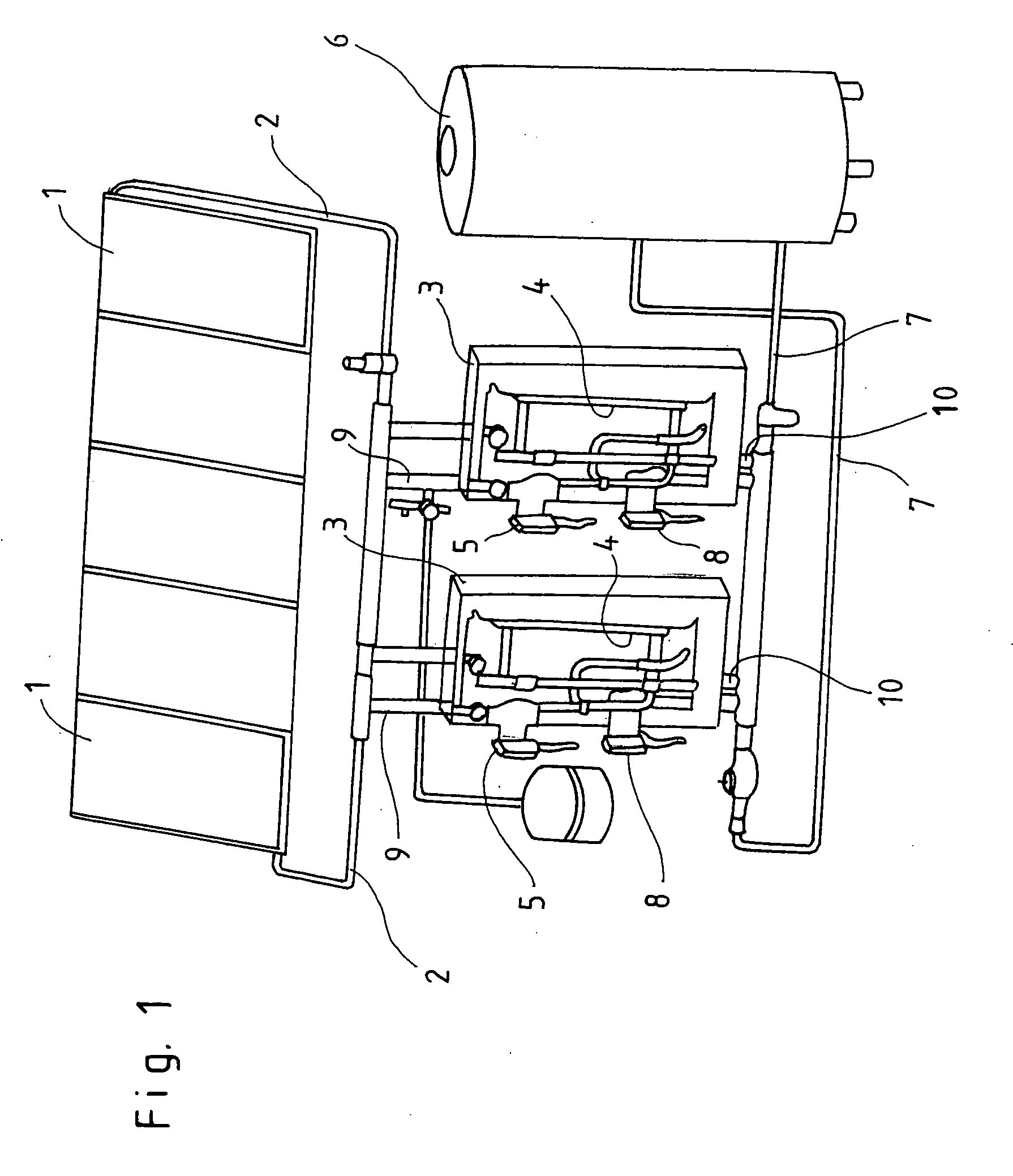

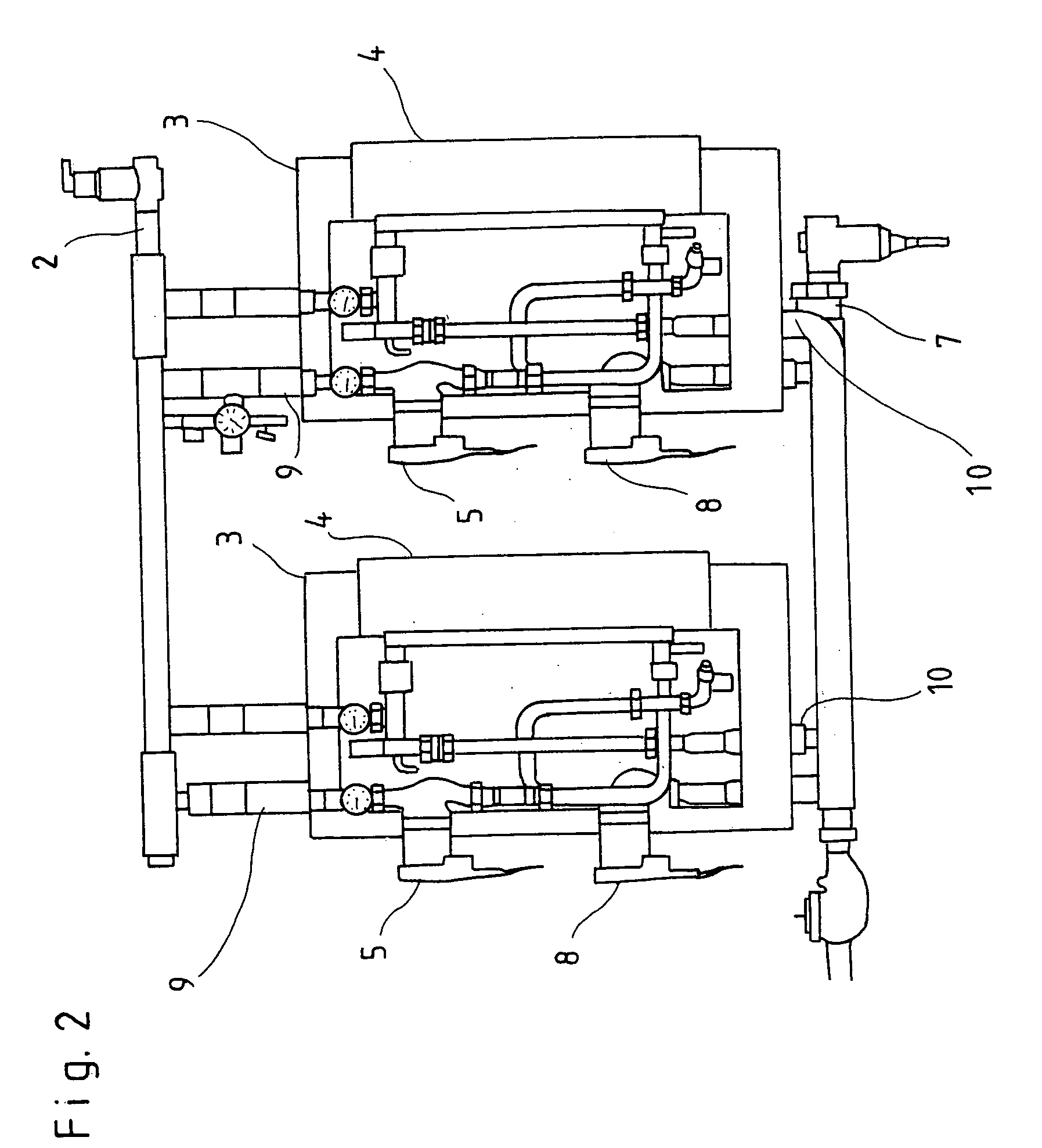

[0016]The solar heat powered system in FIG. 1 encompasses solar collectors 1, which are arranged on a roof, for example. A solar fluid is guided to heat transfer stations 3 via lines 2. A heat exchanger 4 is arranged in each heat transfer station 3. The solar fluid is conveyed by a pump 5; it flows through the heat exchanger 4 and back again to the solar collector 1 via the line 2.

[0017]The solar heat powered system furthermore encompasses an accumulator 6. A secondary heat carrier is guided out of this accumulator 6 to the heat transfer stations 3 via lines 7 and is likewise guided through the heat exchanger 4 by means of pumps 8.

[0018]Provision is made according to the invention for the line 2 from the solar collectors 1 to the heat exchangers 4 to be divided into two partial lines 9. Both heat exchangers 4 are arranged parallel to one another; standardized heat transfer stations 3 can be used thereby. The line 7 for the industrial water is necessarily also divided into partial li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com