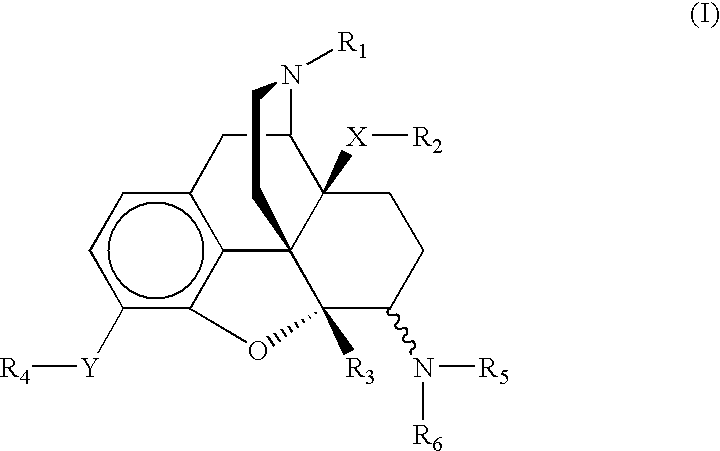

6-Aminomorphinane Derivatives, Method for the Production and Use Thereof

a technology of aminomorphinane and derivatives, applied in the field of6aminomorphinane derivatives, can solve the problems of significant disadvantages of treatment, risks such as bleeding, infections or cartilage damage, and injections into affected tissue or joints, and achieves the effects of reducing side effects and toxicity, reducing the risk of bleeding, and prolonging the analgesic effect period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of (4,5α-epoxy-3-hydroxy-14β-methoxy-17-methylmorphinan-6α-ylamino)-acetic acid-tert.-butylester (Compound 1) and (4,5α-epoxy-3-hydroxy-14β-methoxy-17-methylmorphinan-6β-ylamino)-acetic acid-tert.-butylester (Compound 2).

[0090]

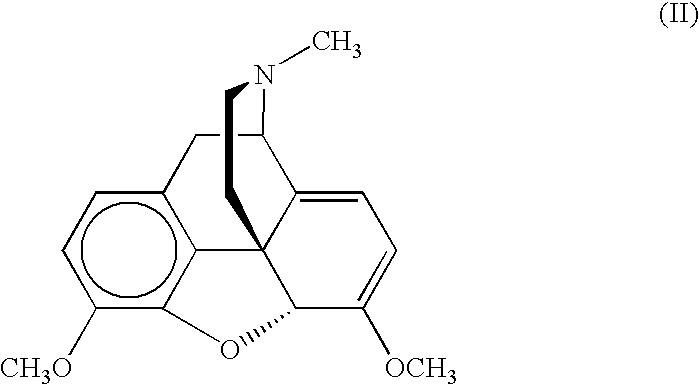

[0091]A solution of 14-O-methyloxymorphone hydrobromide (H. Schmidhammer et al., Helv. Chim. Acta 1990, Vol. 71, pp. 1179-1783) (2.36 g, 5.96 mmol) and glycine-tert.-butylester hydrochloride (1.11 g, 6.62 mmol) in absolute MeOH (100 ml) was stirred for 1 hour under N2 at room temperature. Then a solution of NaCNBH3 (0.55 g, 8.75 mmol) in MeOH (50 ml) was added in drops over 20 min. and the solution stirred further under N2 at room temperature. After 19 h H2O (20 ml) was added and the mixture evaporated. The residue was mixed with H2O (400 ml), alkalized with concentrated ammonia, saturated with NaCl and extracted with Et2O (1×100 ml, 3×50 ml). The combined organic phases were washed with H2O (1×200 ml) and saturated NaCl solution (1×200 ml), dried (N...

example 2

Synthesis of (4,5α-epoxy-3-hydroxy-14β-methoxy-17-methylmorphinan-6α-ylamino)-acetic acid sesqui(trifluoroacetate) (Compound 3•1,5 TFA)

[0094]

[0095]A mixture of Compound 1 (0.18 g, 0.42 mmol) and 30% trifluoroacetic acid (TFA) in CH2Cl2 (7 ml) was stirred at room temperature for 9 h and then evaporated. The residue (0.26 g of orange foam resin) was crystallised out of i-PrOH / Et2O / MeOH. The expected bis(trifluoroacetate) is not obtained, but instead the sesqui(trifluoroacetate), which has been proven by several elementary analyses. Yield 0.13 g (57%) of beige 3•1,5 TFA: Fp >190° C. (Brkd.); IR (KBr): 3428 (OH), 1677 (C═O) cm−1; 1H-NMR (D2O): δ 6.90 (d, J=8.4, 1 arom. H); 6.81 (d, J=8.4, 1 arom. H); 4.47 (dd, 3J=3.0, 4J=1.0, H—C(5)); 3.87 (d, J=1.4, C(6)-NH—CH2) 3.35 (s, CH3O—C(14)); 2.94 (s, CH3N); ESI-MS: m / z 375 (M++1).

example 3

Synthesis of (4,5α-epoxy-3-hydroxy-14β-methoxy-17-methylmorphinan-6β-ylamino)-acetic acid sesqui(trifluoroacetate) (Compound 41, 5 TFA)

[0096]

[0097]A mixture of Compound 2 (0.30 g, 0.70 mmol) and 30% trifluoroacetic acid (TFA) in CH2Cl2 (11 ml) was stirred at room temperature for 5 h and then evaporated. The residue (0.43 g of yellow foam resin) was crystallised out of i-PrOH / Et2O / MeOH. The expected bis(trifluoroacetate) is not obtained, but instead the sesqui(trifluoroacetate), which has been proven by several elementary analyses. Yield 0.21 g (55%) of beige 4•1,5 TFA: Fp >210° C. (Brkd.); IR (KBr): 3419 (OH), 1677 (C═O) cm−1; 1H-NMR (D2O): δ 6.89 (d, J=8.6, 1 arom. H); 6.83 (d, J=8.6, 1 arom. H); 4.90 (d, J=7.8, H—C(5)); 4.04 (s, C(6)-NH—CH2—); 3.32 (s, CH3O—C(14)); 2.91 (s, CH3N); ESI-MS: m / z 375 (M++1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com