Thin multi-chip flex module

a multi-chip, flexible technology, applied in the direction of printed circuit manufacturing, printed circuit components, stacked and attached pcbs, etc., can solve the problems of premature failure, ineffective circulation of air as cooling fluid, and considerable heat generation during operation, so as to achieve cost saving, cost saving, and efficient thermal communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

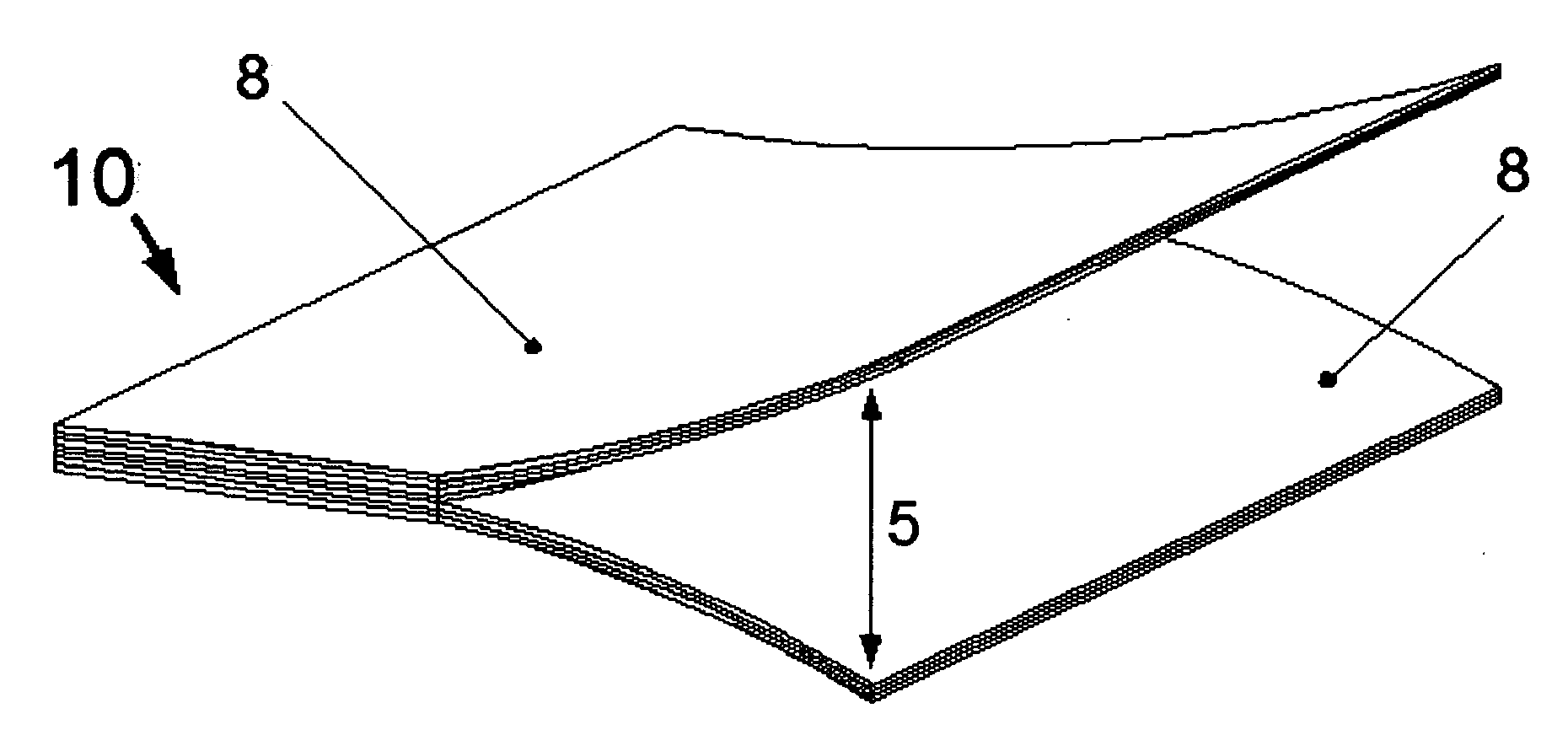

[0053]The present invention addresses the designs of effective solutions to optimize the offering and differentiation for thickness reduction, module densities and relative cost effectiveness. These parameters are balanced per density requirement. For instance, a design that can meet and optimize the attributes of a memory module at the low densities (2 GB and 4 GB) can use a central flexible circuit that places the chips in a mirror image configuration and that offers the benefit of using a lesser amount of flexible circuit and hence enables lower cost. Chips in a mirror image around a flex enable simpler electrical design. Furthermore, the centrally-located flex reduces thickness and when coupled with other features in the current invention (including those features dealing with signal length symmetry, grounding strategies, and the connection interface), would produce an extremely thin and relatively cost effective solution at the low densities.

[0054]Skilled artisans will apprecia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com