Staged Actuation Shear Sub for Use Downhole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

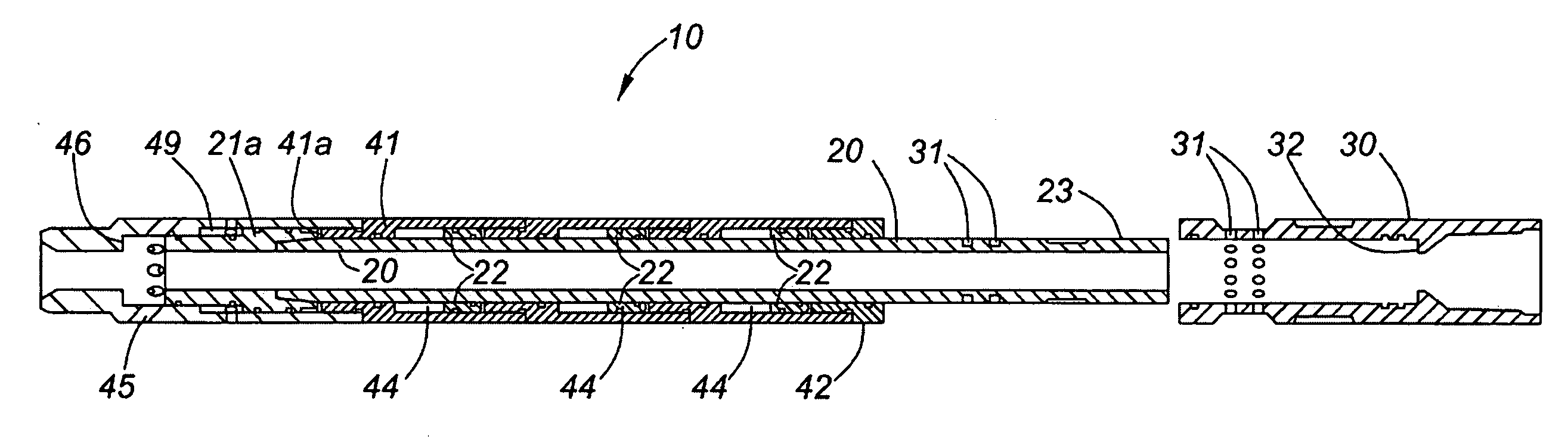

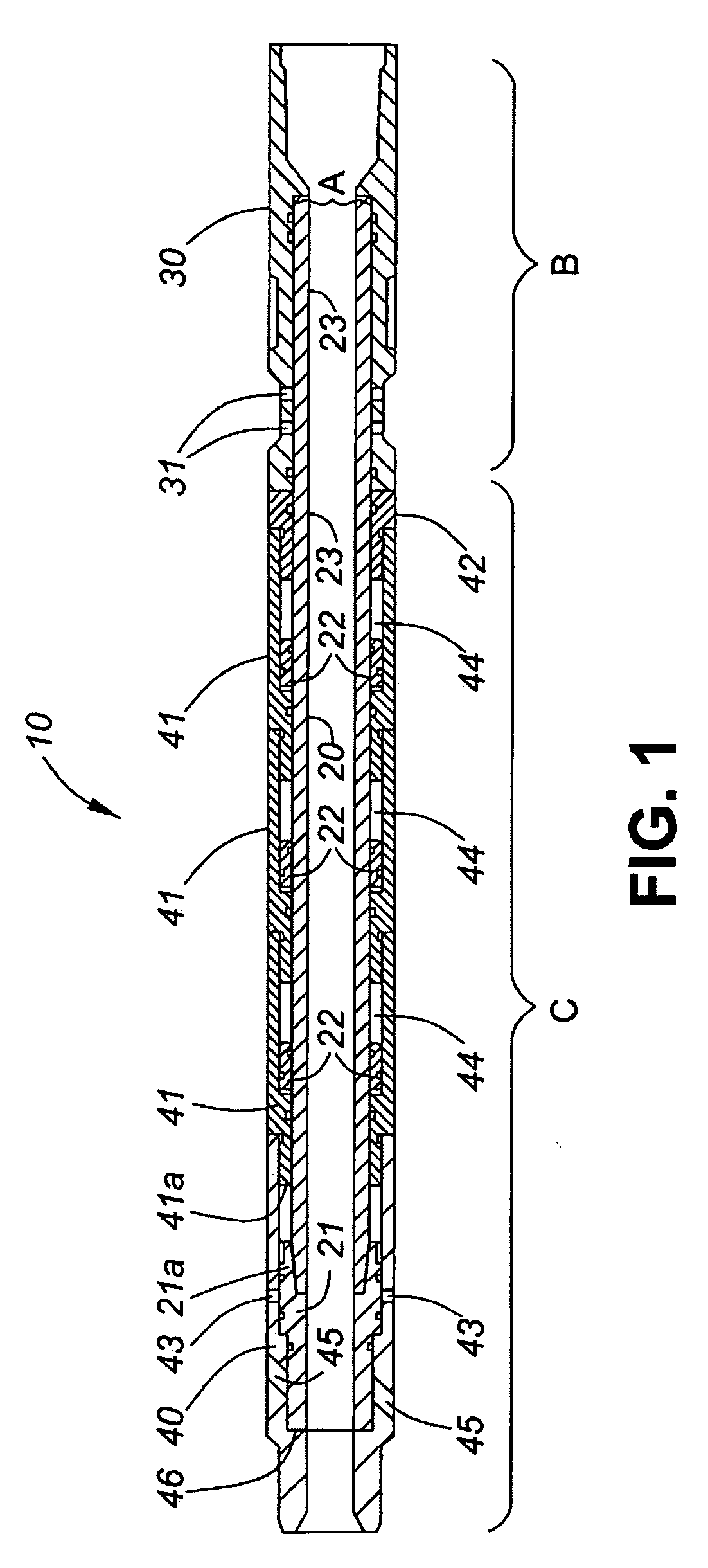

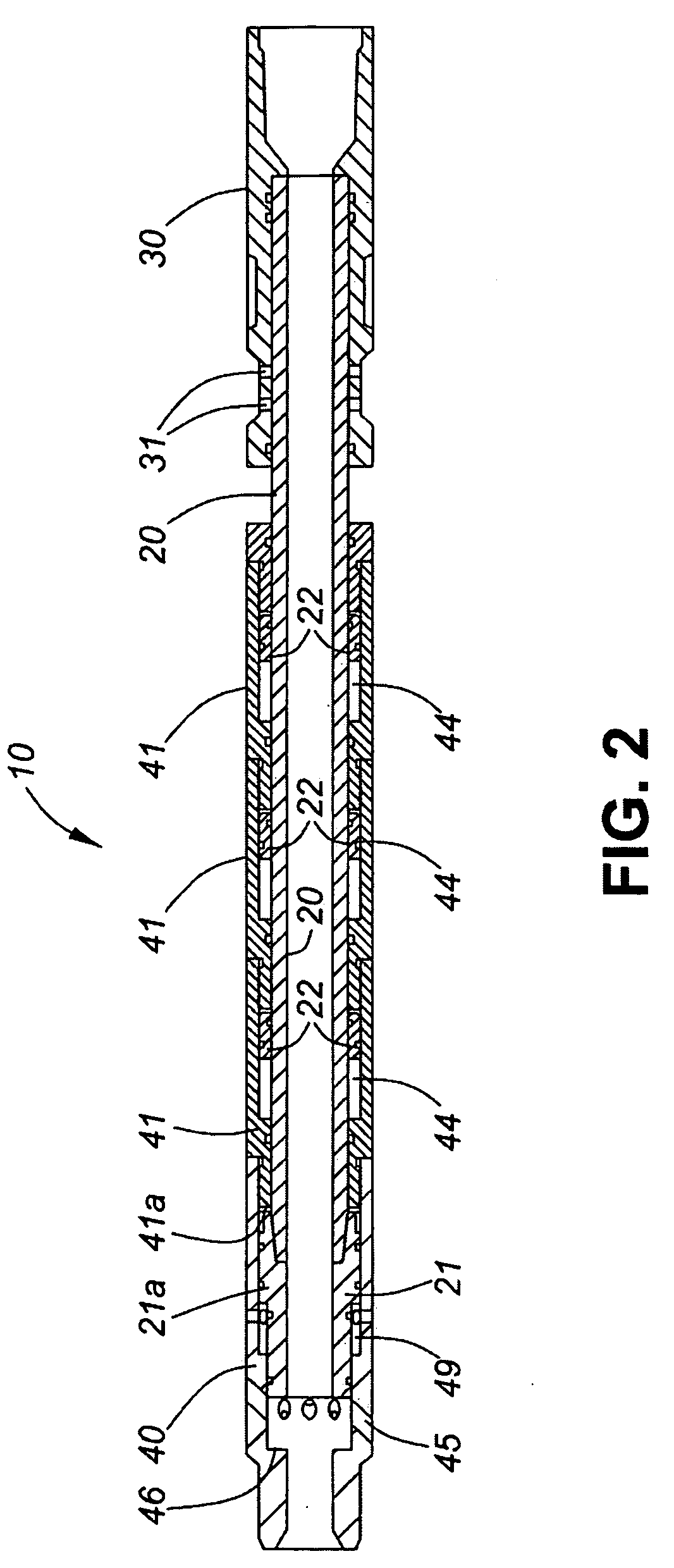

[0028]Generally, the present invention provides a downhole shear assembly for actuating a work string tool or process. Specifically, the device incorporates dampening means for minimizing post-shear inertial force within the work string and related equipment. Minimizing the post-shear inertial force prevents damage or premature actuation of sensitive components within the work string, and permits more precise control of forces applied to work string tubing and equipment. This additional degree of precision in force application permits an additional shear point to be incorporated within the assembly for actuation of a second process or function, the second shear mechanism having a higher actuation force threshold. In such dual shear devices, a first shear sleeve may be designated for initiation of a downhole process or to actuate a downhole tool, while the second shear sleeve (set to a higher force threshold) may be assigned to initiate a second possibly independent, process. For exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com