Titanium treatment to minimize fretting

a titanium alloy and titanium treatment technology, applied in the direction of solid-state diffusion coating, waterborne vessels, machines/engines, etc., can solve the problems of increased fretting fatigue, increased fretting wear, and increased fretting wear, so as to reduce the susceptibility of the surface to fretting, reduce the cost of equipment, and reduce the effect of service cost and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

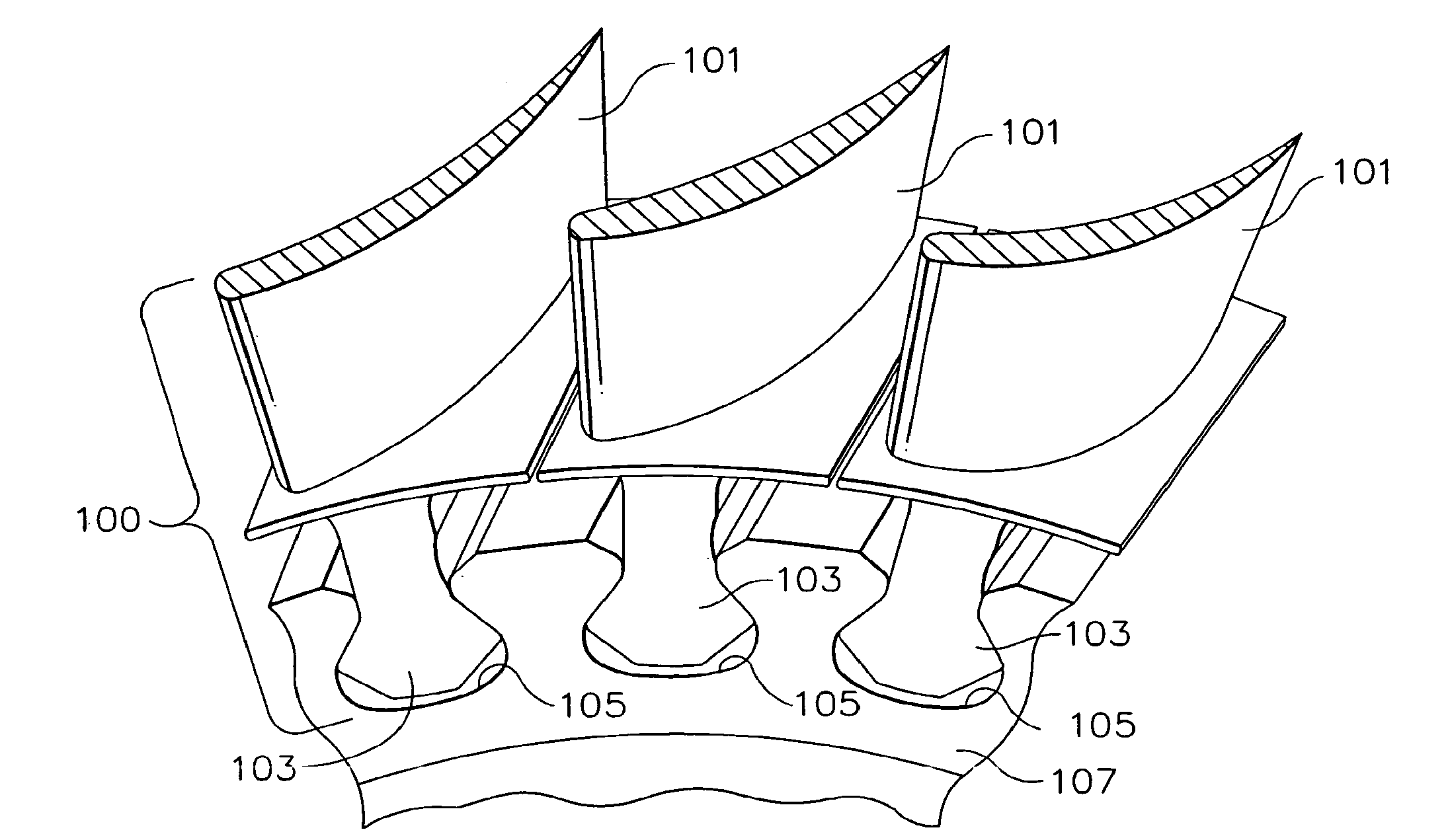

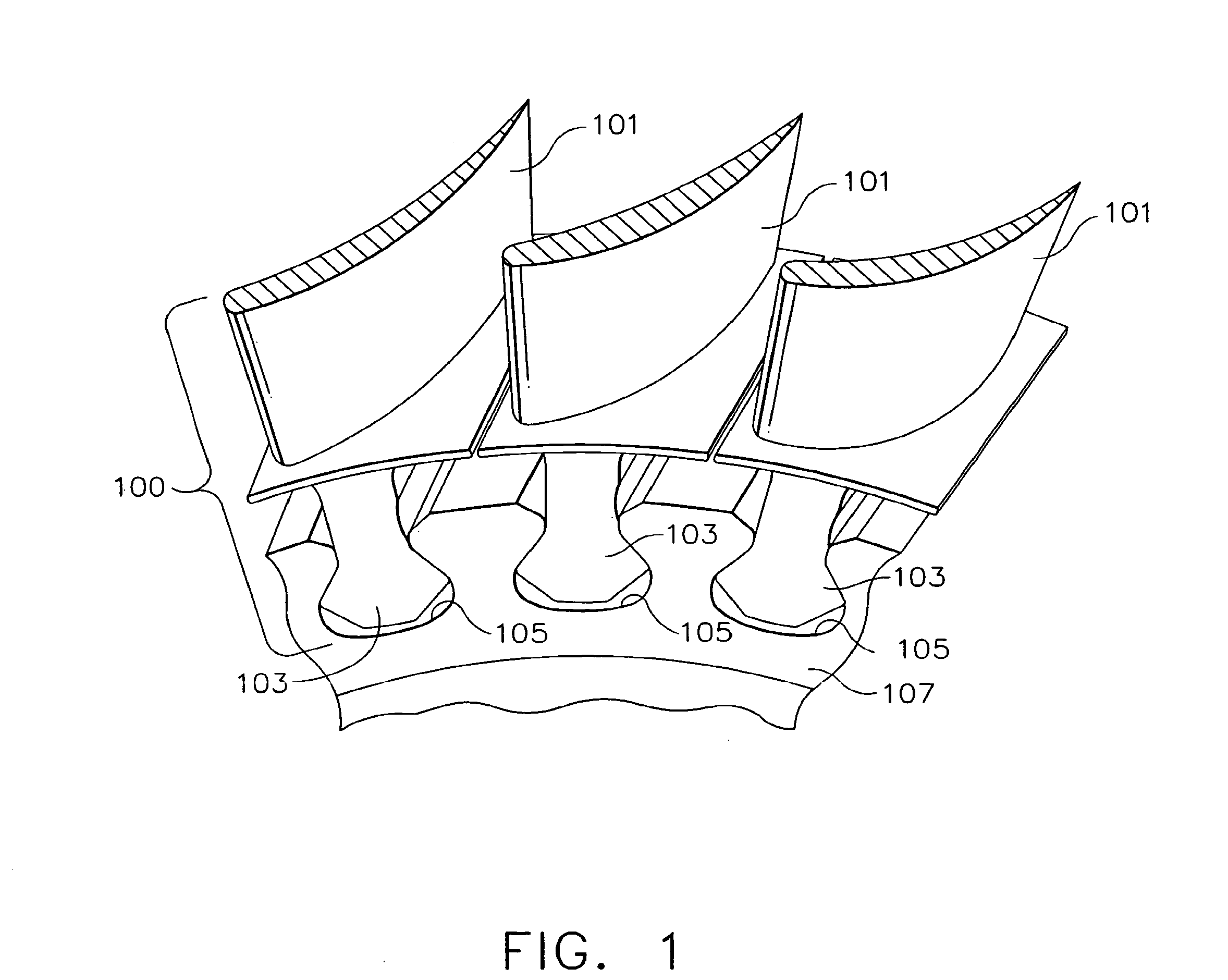

[0029]FIG. 1 is a cutaway view of a section of a high-pressure compressor for a turbine engine according to the present invention. The compressor includes a plurality of blades 100. The blades 100 include an airfoil 101 and a dovetail 103, which is positioned within dovetail slots 105 in a compressor disk 107. The dovetail 103 of the blade 100 retains the blade 100 during operation of the gas turbine engine. The blade 100 and the compressor disk 107 according to the invention include titanium and have one or more surfaces that are in frictional contact that are carburized to produce a surface having a carburized zone 401 (see FIGS. 4-9). In addition, one or more of the surfaces of the dovetail 103 and dovetails slots 105 of the compressor disk 107 are coated with a lubricant coating 601 (see FIGS. 6-9).

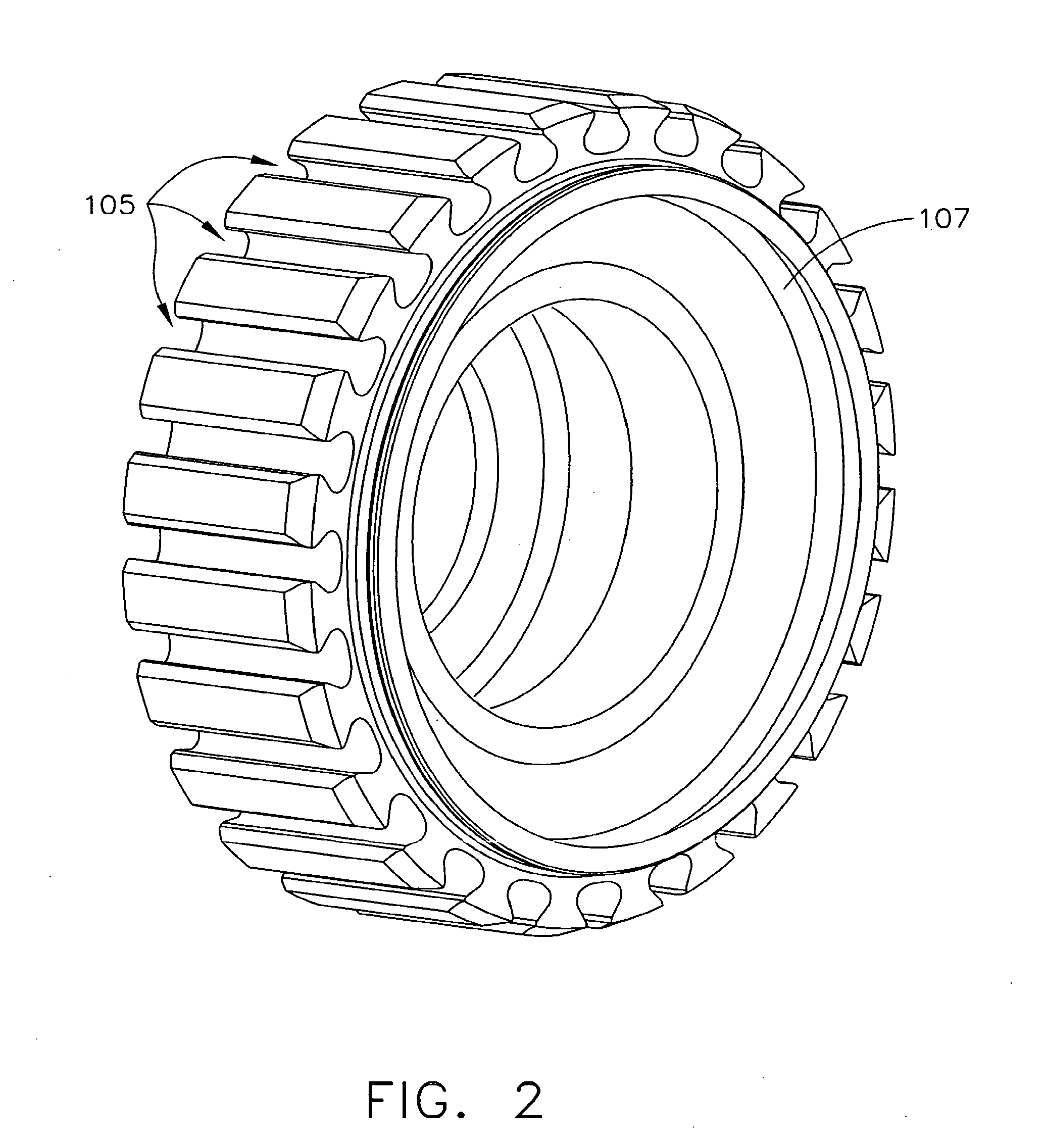

[0030]FIG. 2 shows a perspective view of a compressor disk 107 according to an embodiment of the present invention, wherein FIG. 2 shows dovetail slots 105 into which the dovetail 103...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com