Electroluminescent device

a technology of electroluminescent devices and electrodes, applied in the direction of discharge tubes/lamp details, discharge tubes luminescnet screens, electric discharge lamps, etc., can solve the problems of inability to extract outside the device, and the method has not taken into account the reflection of light at the boundary surface between the transparent electrode layer and the low-refractive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

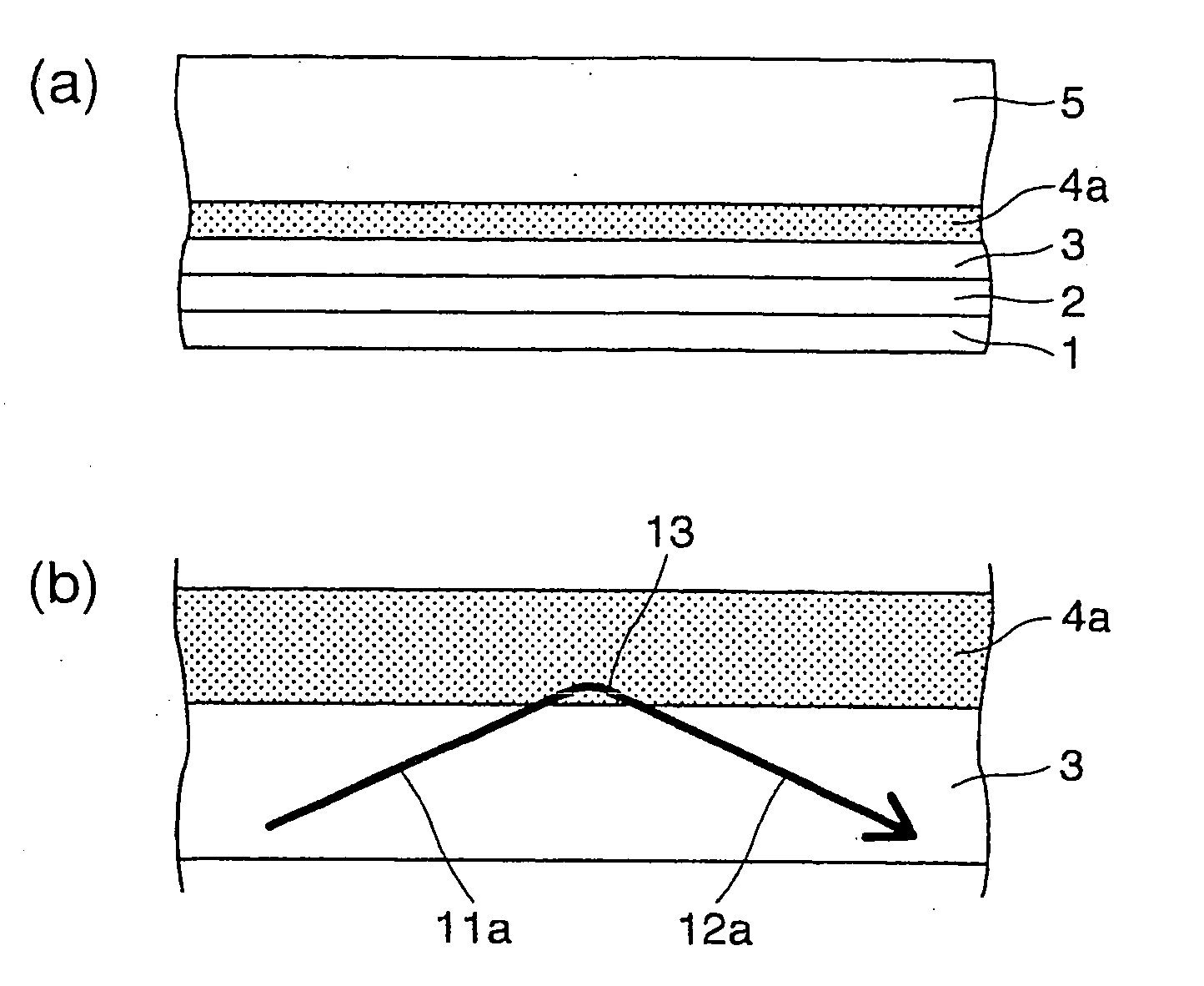

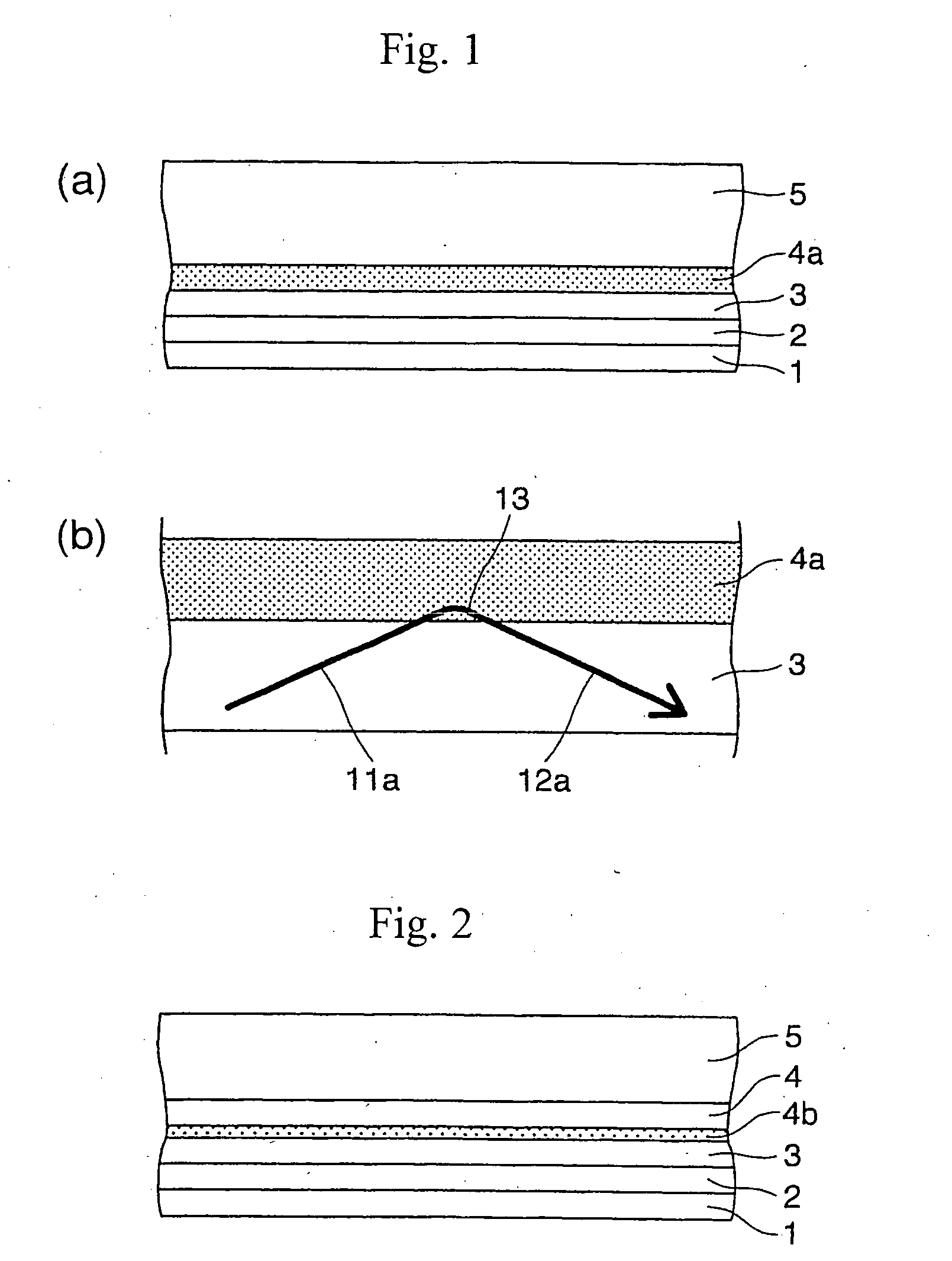

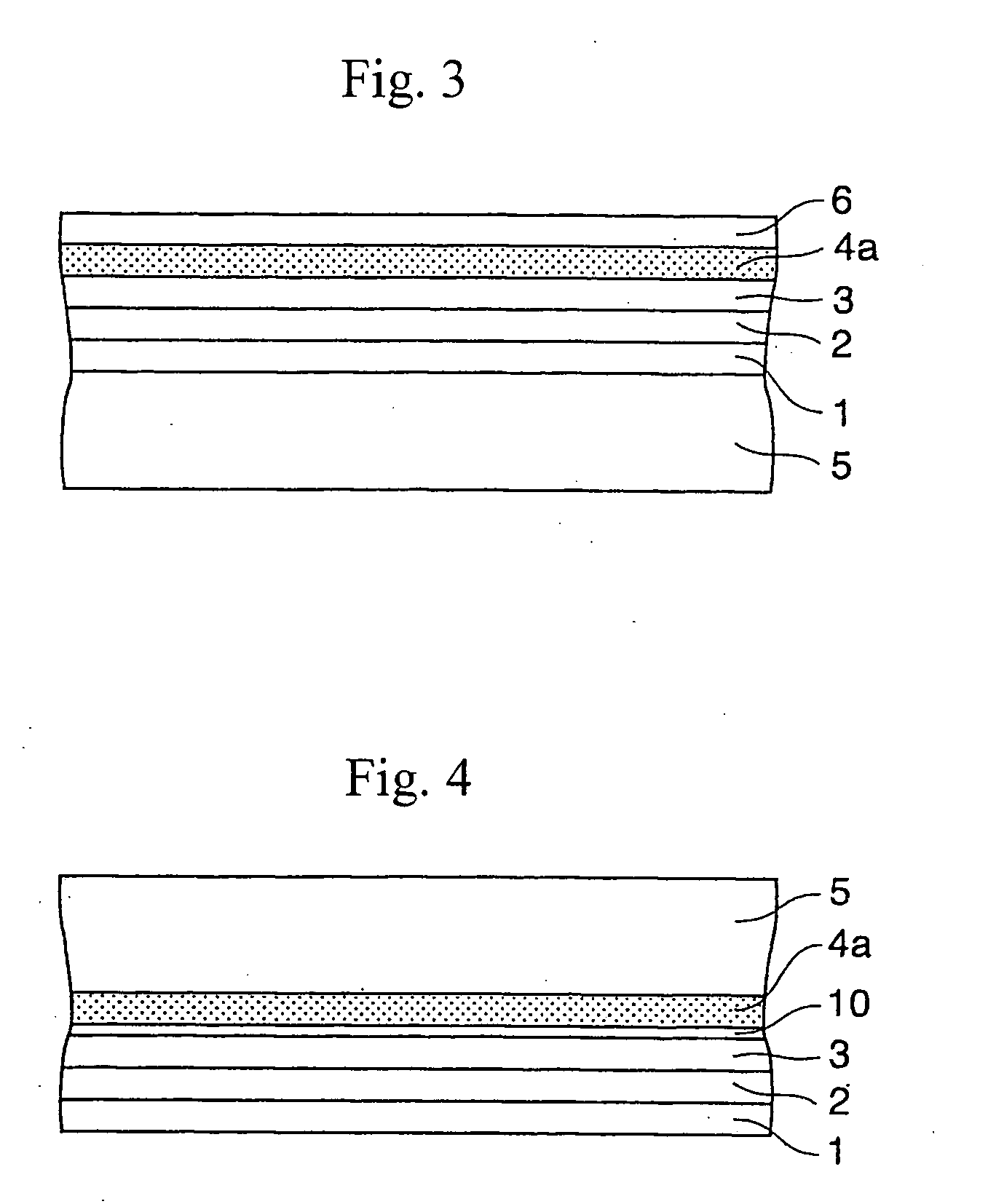

Image

Examples

examples

[0288]The present invention is described in more detail by Reference Examples corresponding to Examples, but the Reference Examples are only illustrative and not intended to limit the scope of the present invention. Meanwhile, in the following Reference Examples and Comparative Examples, neither cathode nor electroluminescent layer were formed, and a fluorescent pigment layer was formed on a transparent electrode layer. The fluorescent pigment layer was irradiated with excitation light to extract a fluorescence from the side of a substrate and measure an amount of light extracted using a fluorescence spectrometer / luminance meter manufactured by Hitachi Ltd., in the following procedure. That is, excitation light having a wavelength of not more than 400 nm was irradiated on a rear surface (the side on which fluorescent pigment was vapor-deposited) of the obtained laminate, from the side of the fluorescent pigment layer, and an intensity of the extracted light having a wavelength of 42...

reference examples 1 to 5

[0291]These Reference Examples were conducted for explaining the first invention.

reference example 1

Corresponding to Embodiment (1)

[0292]A glass plate having a thickness of 0.7 mm and a size of 75 mm square which was composed of a non-alkali glass “AN100” produced by Asahi Glass Co., Ltd., was immersed in 0.1N nitric acid for about one hour to subject the surface thereof to degreasing treatment, washed with pure water and then dried in an oven at 60° C., thereby obtaining a glass substrate 1.

[0293]Separately, a small amount of an acid catalyst (aluminum acetylacetonate) was added to a mixed solution containing 30% by weight of an oligomer of tetramethoxysilane (“MS51” produced by Mitsubishi Chemical Corporation), 50% by weight of BtOH, 8% by weight of desalted water and 12% by weight of MeOH, and then silica fine particles having an average particle size of 120 nm and containing particles having a particle size of from 70 to 150 nm in an amount of not less than 60% by weight, were added to the resultant solution such that the weight ratio of the silica fine particles to MS51 was 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com