Three piece welded plastic pallet

a three-piece, plastic pallet technology, applied in the field of pallets, can solve the problems of insufficient strength of plastic pallets with a lower package height, heavy weight of pallets, and large amount of plastic materials, and achieve the effects of convenient cleaning, convenient connection, and sufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

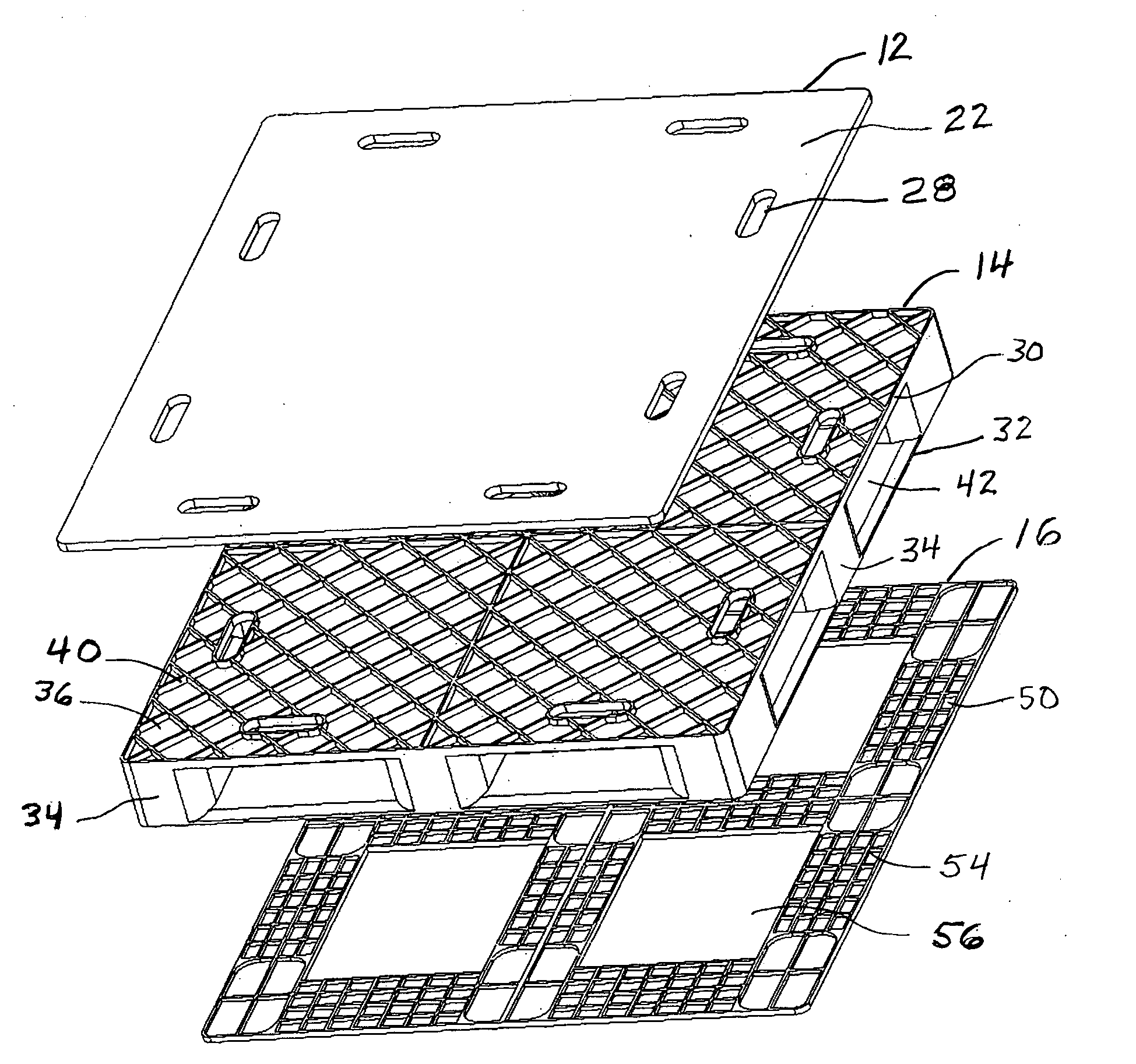

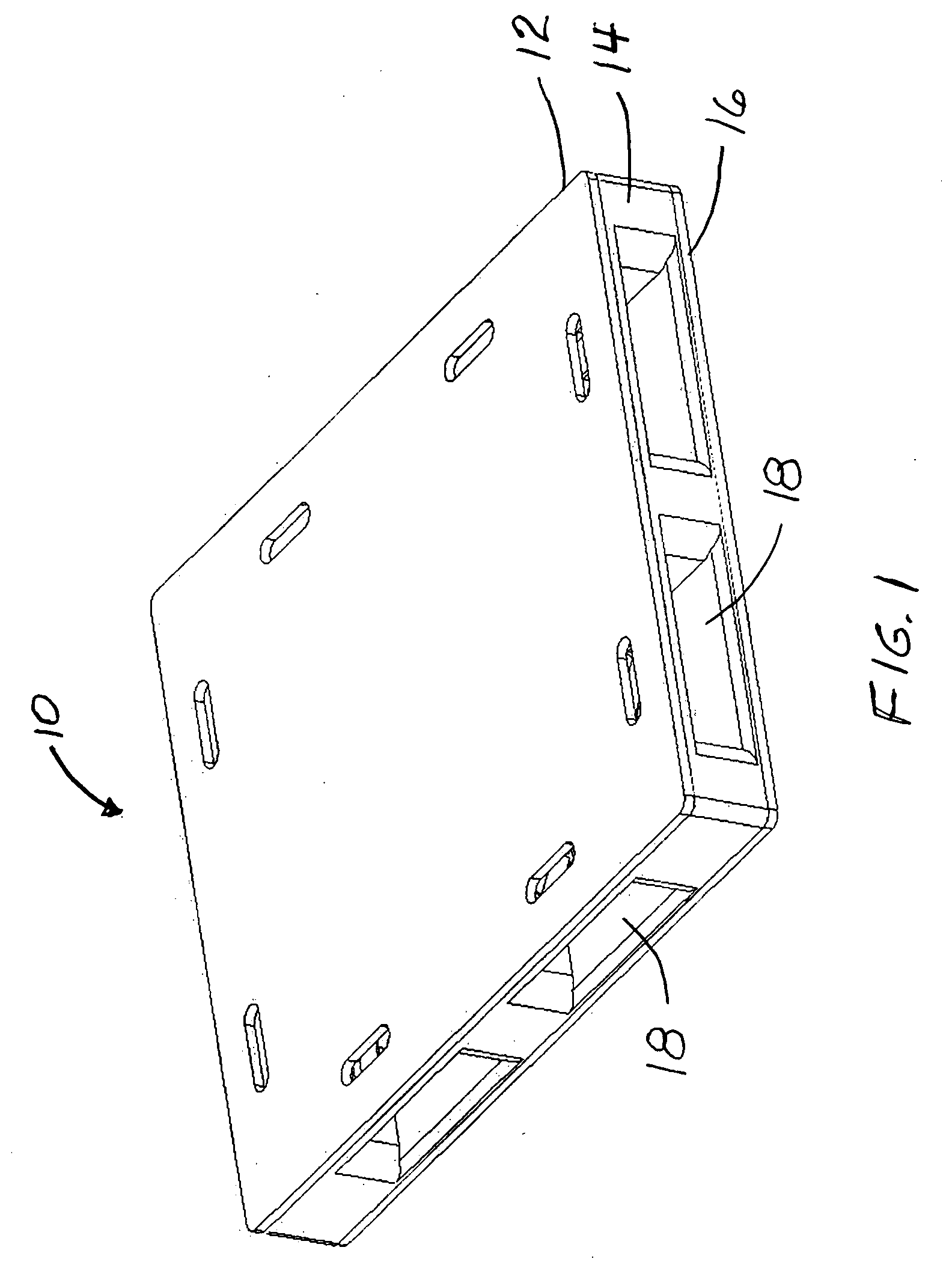

[0019]Illustrated in FIGS. 1-4 of the drawings is a pallet 10 according to the present invention which includes a top deck 12, a middle deck 14 and a bottom deck 16. A plurality of entryways 18 are provided on the sides of the pallet with each side being constructed with two entryways to receive the prongs of a lifting device such as a forklift. The top, middle and bottom decks are all made of a synthetic resin or plastic material such as polypropylene or polyethylene. The three decks preferably are molded using an injection molding process.

[0020]The top deck 12 has a smooth upper surface 22 as shown in FIGS. 1-3 and a lower surface 24 having a plurality of ribs 26 which cross each other to form a plurality of diamond shaped boxes as shown in FIG. 4. The top deck also is provided with a plurality of holes constituting hand holds 28 adjacent the sides thereof.

[0021]As shown in FIGS. 2, 3 and 4, middle deck 14 is constructed having an upper plate portion 30 and a lower plate portion 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com