Cooling system for carpet/wood ash

a cooling system and carpet technology, applied in the field of energy production, can solve the problems of difficult to dispose of waste products, ash may smolder and/or ignite, and the ash is a bit combustible, so as to reduce the size of any ash chuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

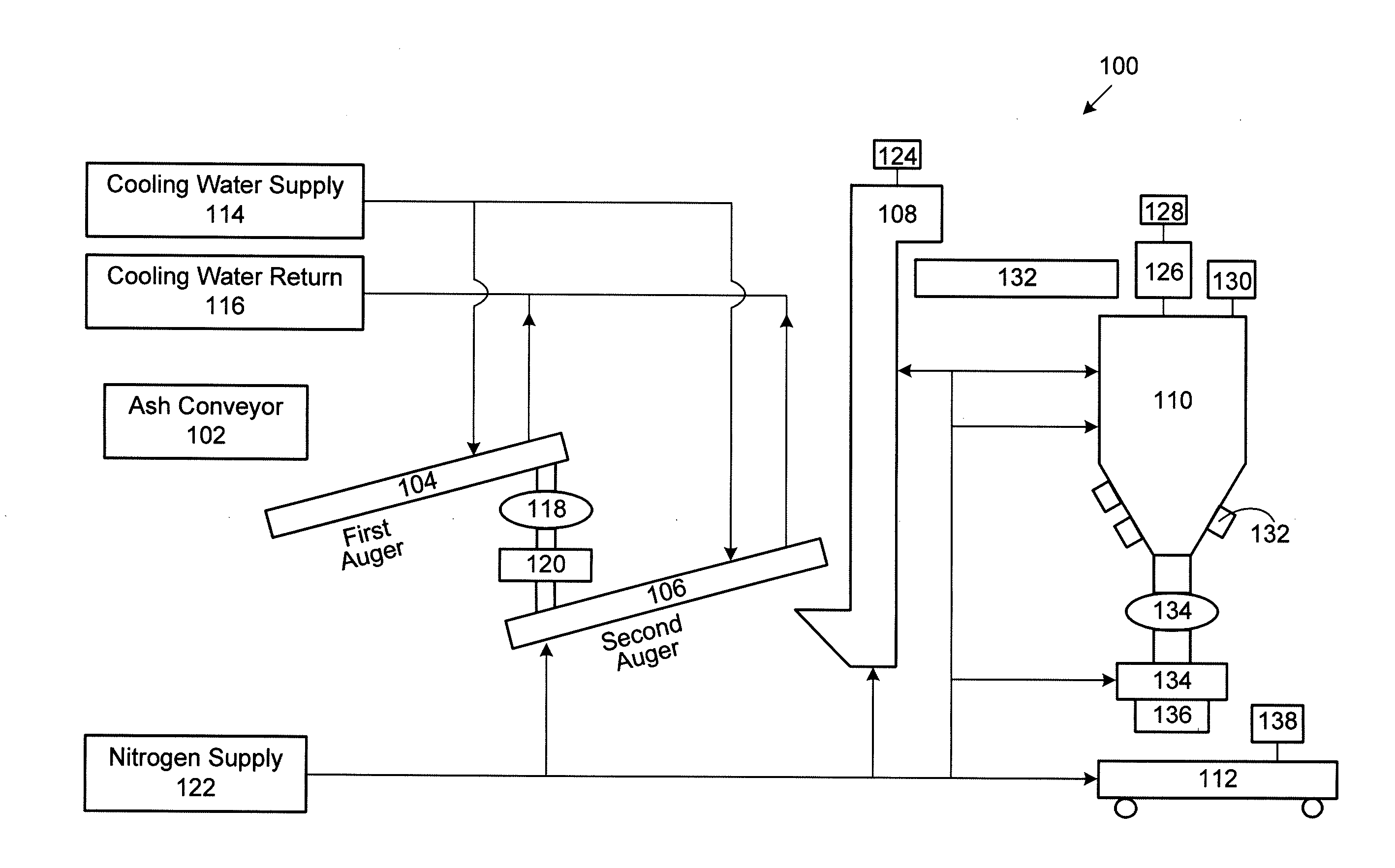

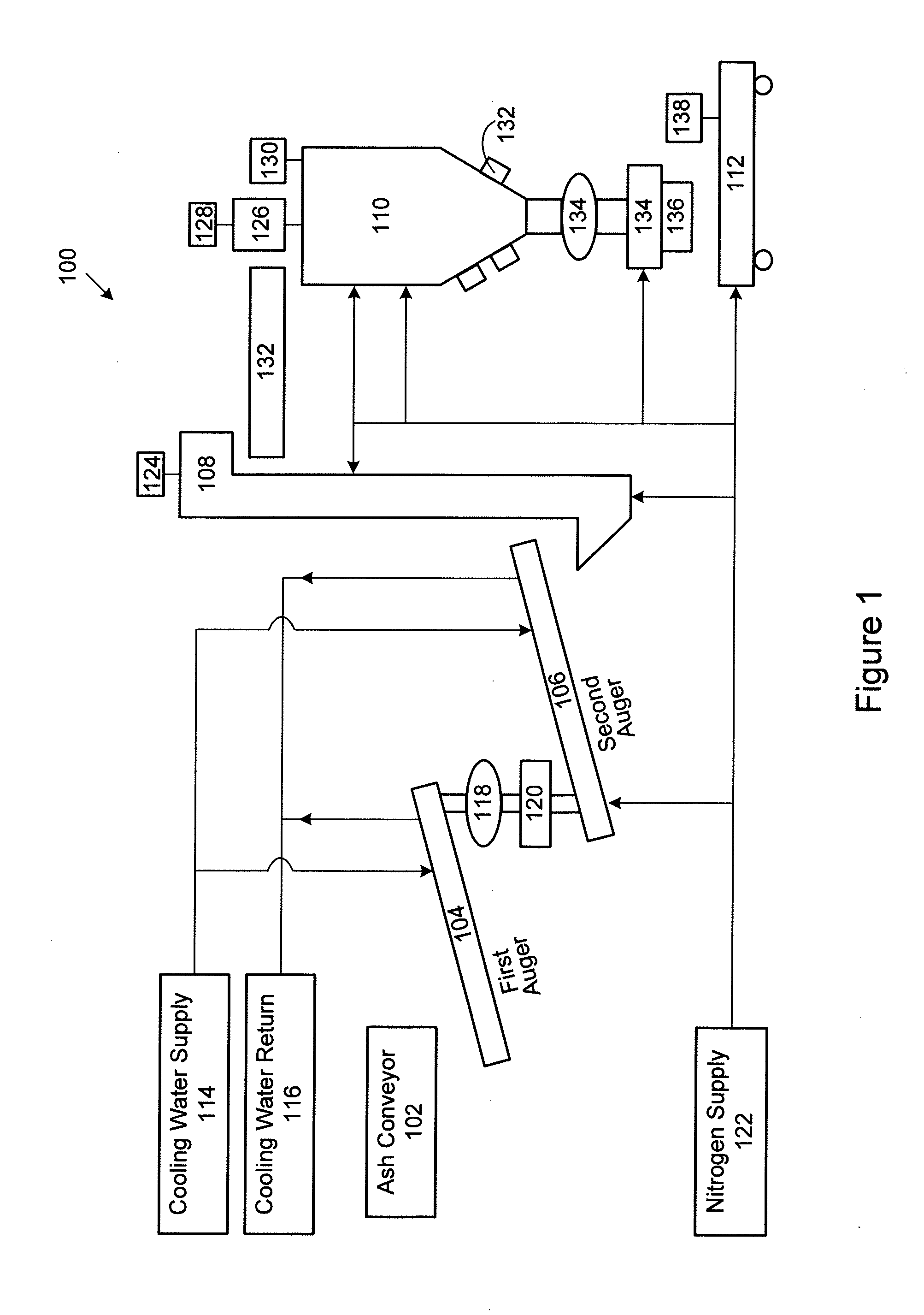

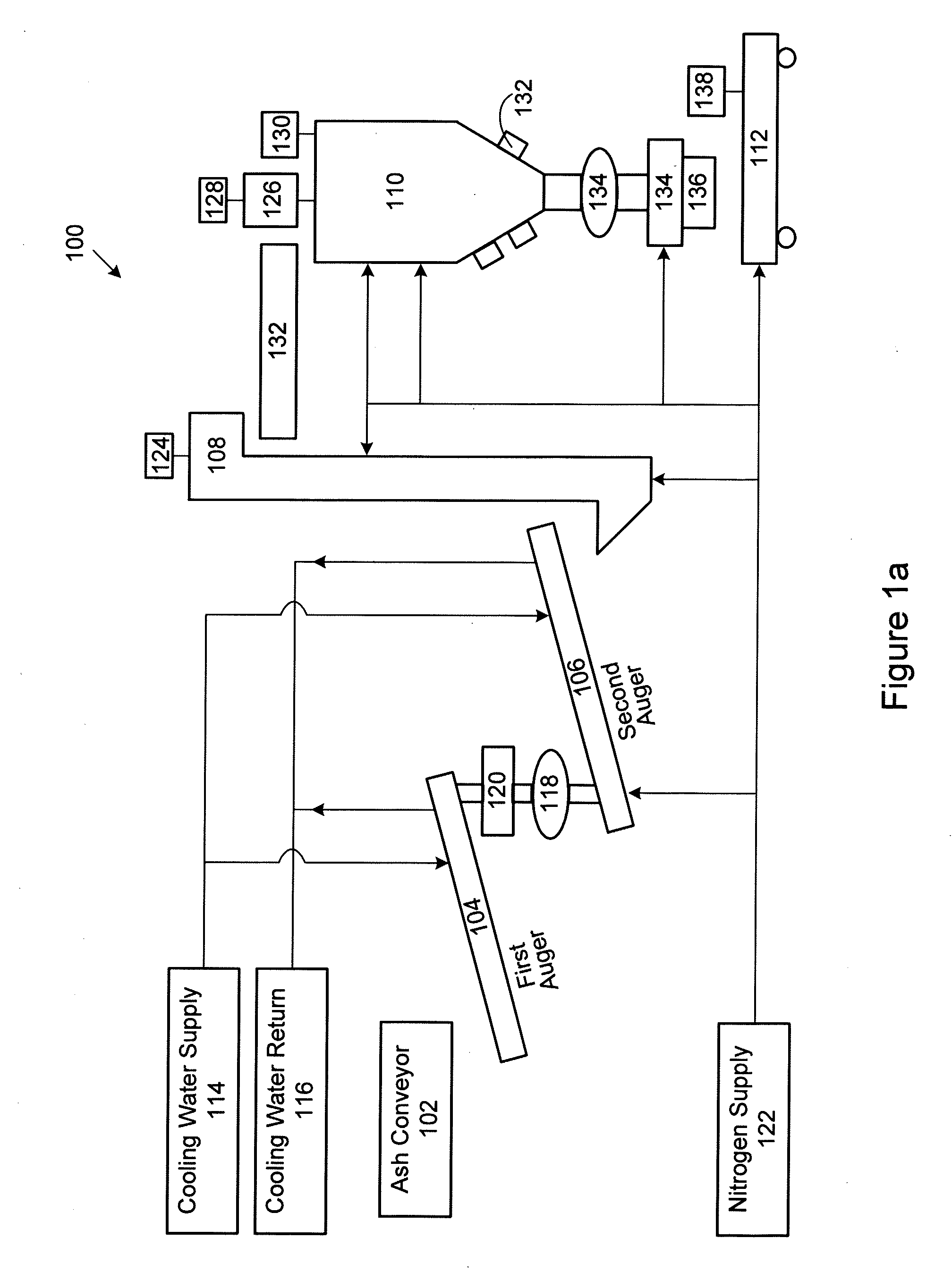

[0020]The present embodiments provide a method and system for transferring, cooling, storing, and unloading a waste product of a thermal conversion process. In one embodiment, the thermal conversion process is a gasification process and the waste product is ash generated from gasification. In another embodiment, the biomass fuel used during the gasification process is a mixture of carpet waste and wood flour, such as described by U.S. application Ser. No. 11 / 052,634.

I. Exemplary Thermal Conversion Process and Biomass Fuels

[0021]The process of gasification may be used to generate steam, such as application steam for use by turbines. Gasification is the thermal conversion of a solid biomass fuel into a hot (over 1,000° F.) synthesis gas that contains combustible gases, such as methane, hydrogen, carbon monoxide, and / or other gases. In the process of gasification, or the conversion of a solid biomass fuel into a gas, there may be an insufficient amount of oxygen to completely burn the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com