Magnetic refrigerating device and magnetic refrigerating method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Hereinafter, the present invention will be described in detail with reference to the drawings.

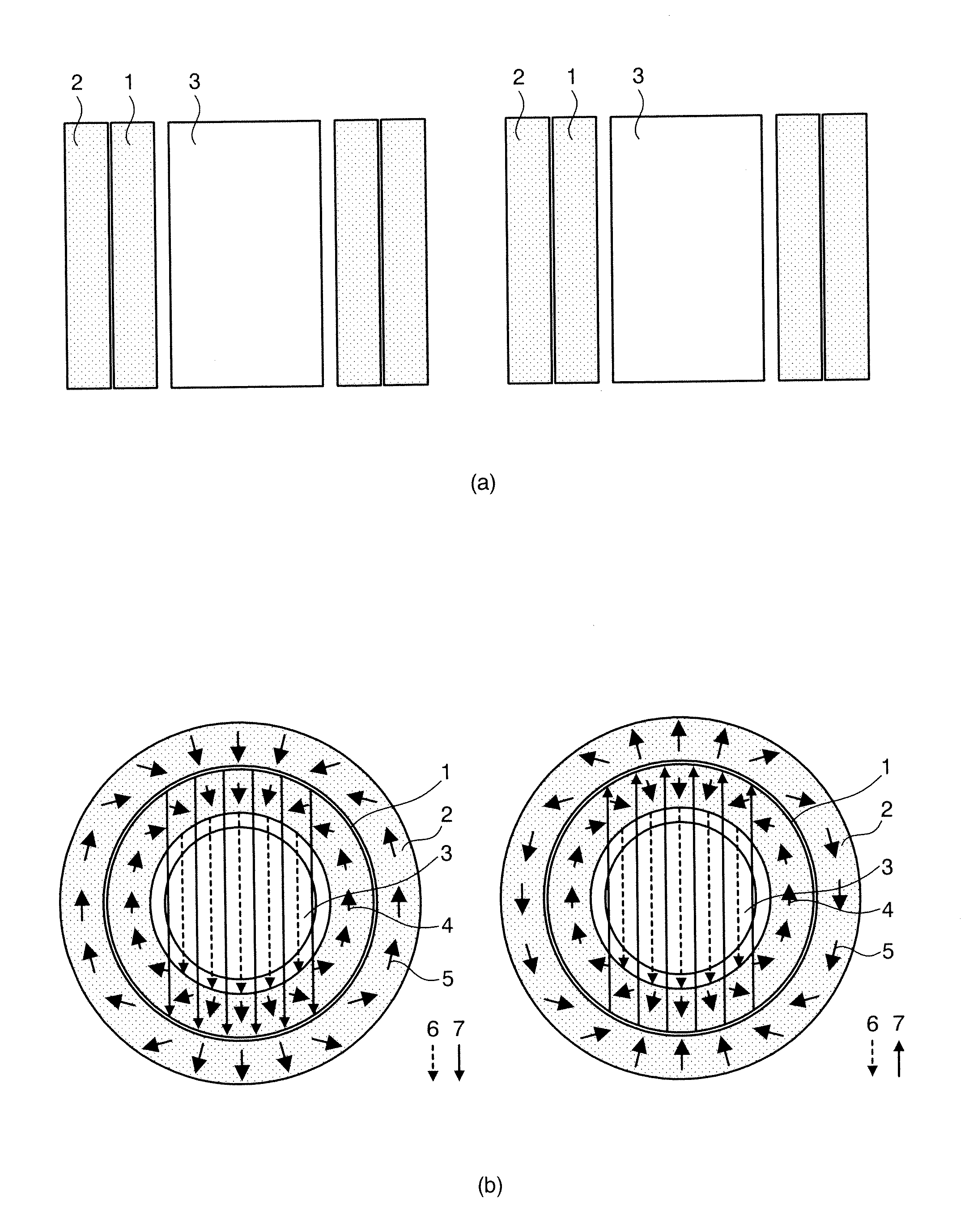

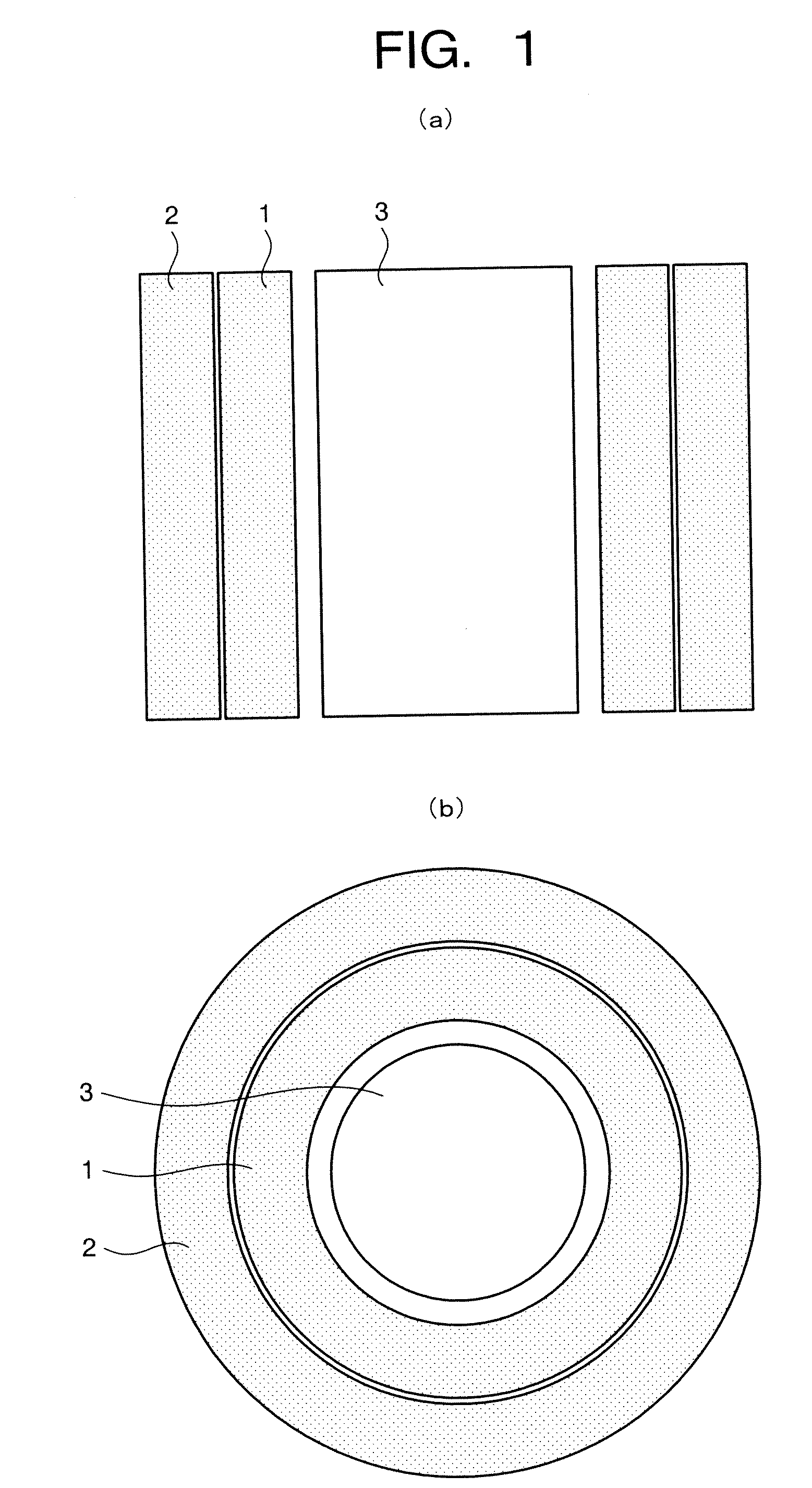

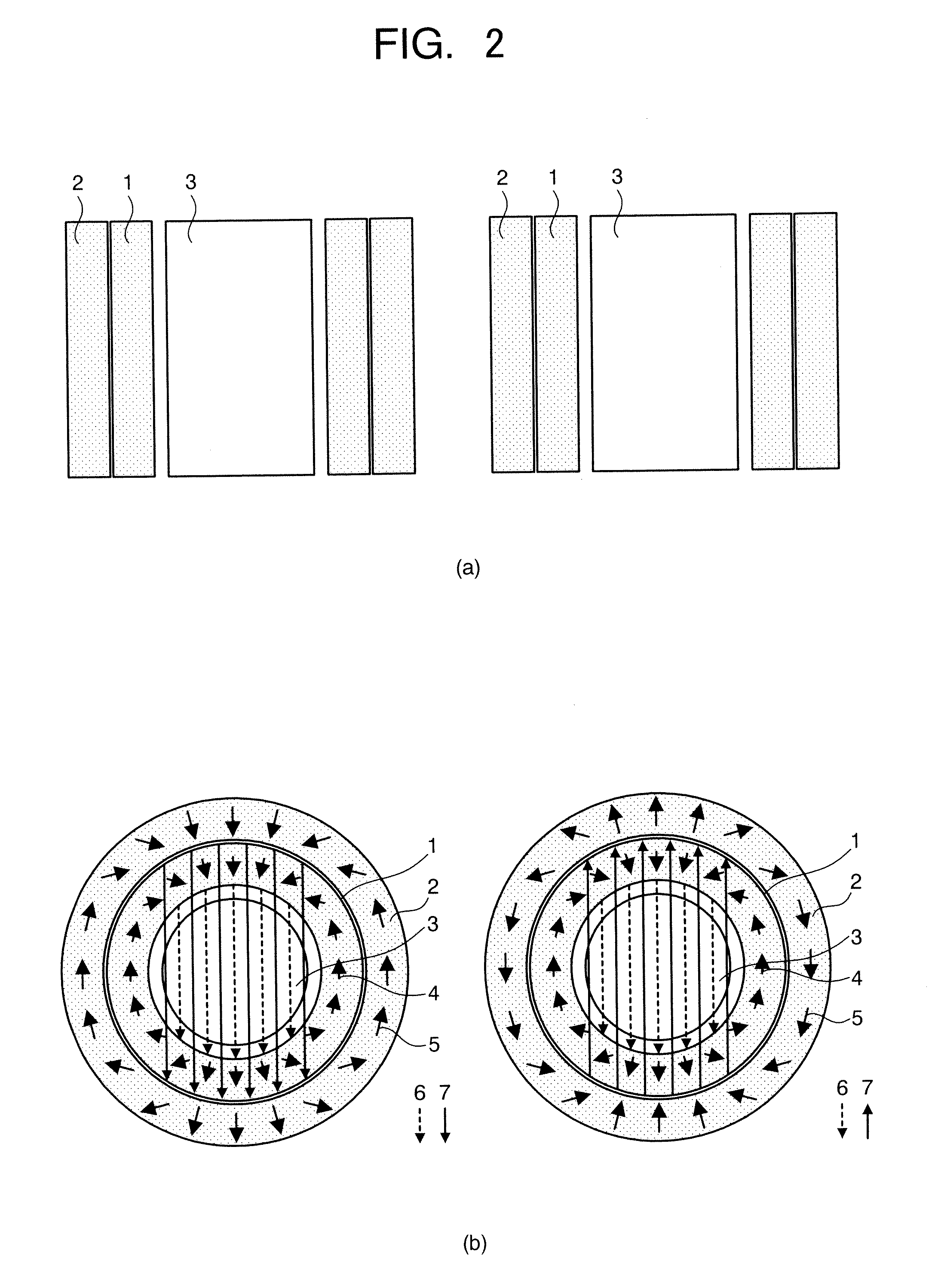

[0044]FIG. 1 is a schematic view illustrating a portion of the magnetic refrigerating device according to an embodiment of the present invention. FIG. 1(a) is directed at the cross section of the magnetic refrigerating device, and FIG. 1(b) is directed at the top plan view of the magnetic refrigerating device. In the present specification, like or corresponding components are designated by the same reference numerals.

[0045]In FIG. 1, the reference numeral “1” designates an inner Halbach type magnet and the reference numeral “2” designates an outer Halbach type magnet. The inner Halbach type magnet is coaxially disposed in the outer Halbach type magnet so as to form the double-structured Halbach type magnet. The reference numeral “3” designates a magnetic refrigerant which may be accommodated into a container (not shown).

[0046]In this embodiment, since the intended heat transfer is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com