Image sensor, single-plate color image sensor, and electronic device

a color image sensor and image sensor technology, applied in the field of image sensors, can solve the problems of affecting the spectral sensitivity the use of the avalanche multiplication layer is not necessarily suitable for miniaturization of the pixel, and the inability to avoid the tendency of decreasing the sensitivity of the image sensor, etc., to achieve the effect of suppressing the decrease of sensitivity and the change of spectral sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

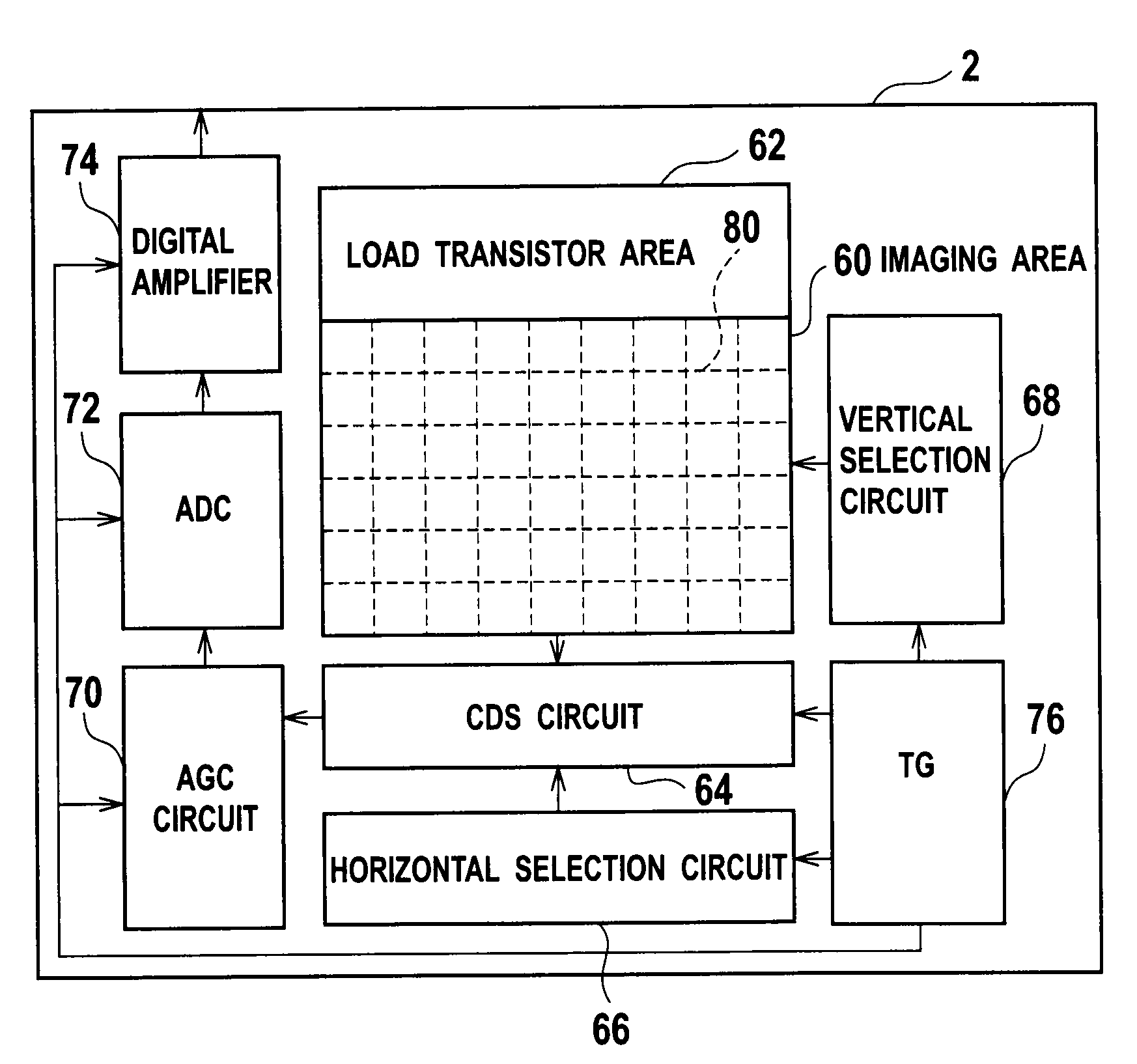

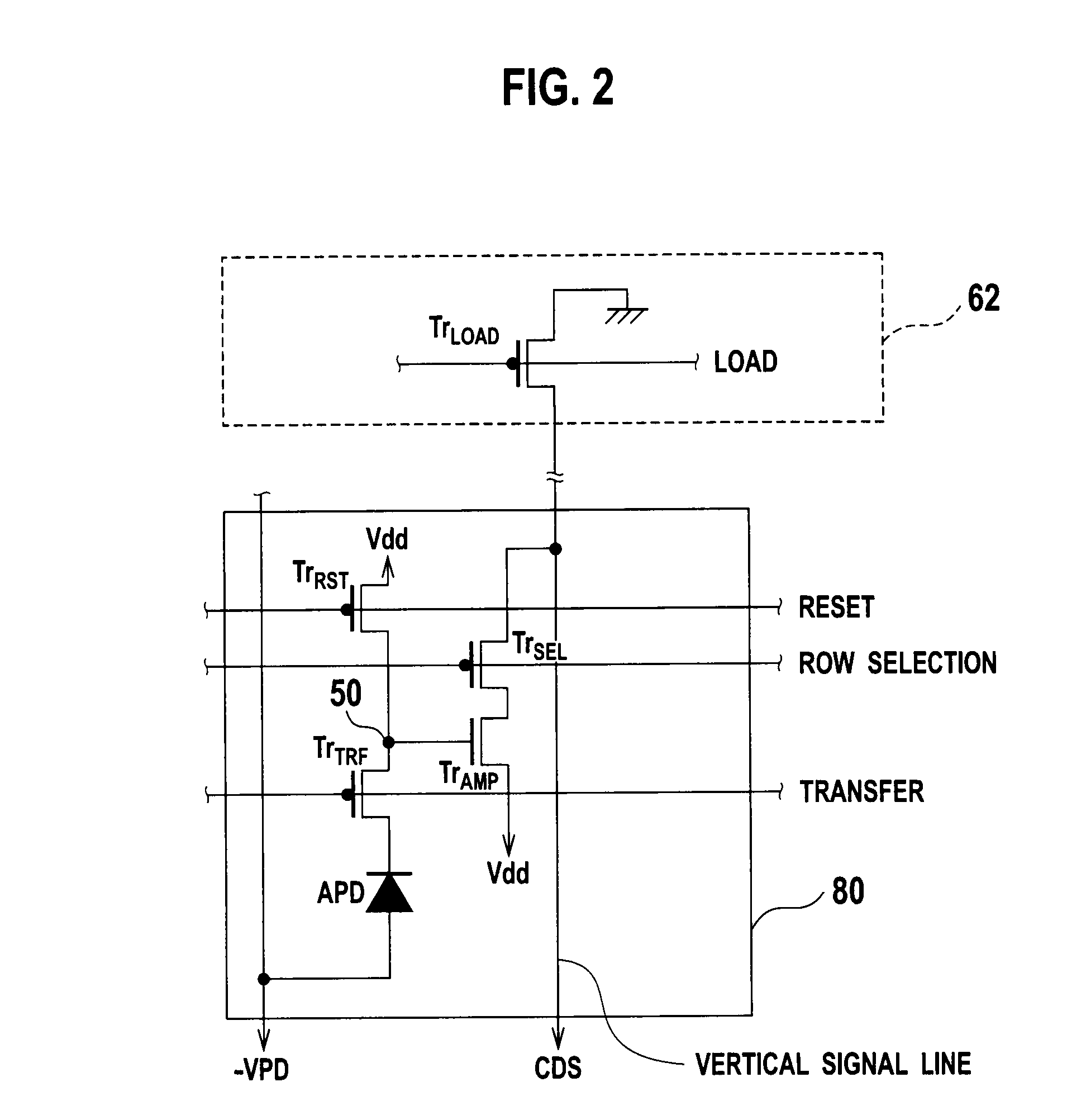

[0036]An image sensor 2 according to a first embodiment of the present invention includes an imaging area 60, a load transistor area 62, a correlated double sampling (CDS) circuit 64, a horizontal selection circuit 66, a vertical selection circuit 68, an automatic gain control (AGC) circuit 70, an analog-digital converter (ADC) 72, a digital amplifier 74 and a timing generator (TG) 76. The imaging area 60 includes a plurality of cells 80, arrayed in a matrix. Each of the plurality of cells 80 functions as a pixel and converts a signal charge, generated from an incident light signal by photoelectric conversion, to a voltage so as to generate an analog signal. The load transistor area 62 is arranged in contact with the imaging area 60. The load transistor area 62 includes a source follower circuit provided in combination with an amplifying transistor of a pixel selected by the vertical selection circuit 68, so as to transmit the analog signal voltage, which is generated by each pixel,...

second embodiment

[0073]A single-plate color image sensor according to a second embodiment of the present invention includes a cell 80 in which four pixels 4a, 4b and 4c are arranged as a Bayer array, as shown in FIG. 11. The pixel 4a is used for blue color (B). Two pixels 4b are used for blue and green colors (B+G). The pixel 4c is used for blue, green and red color (B+G+R).

[0074]The pixel 4a includes a first avalanche photodiode (12a, 13a and 14a) and a first transfer transistor (16A, 22A and 16B), as shown in FIG. 12. The first avalanche photodiode (12a, 13a and 14a) includes a first anode region 12a, a first avalanche multiplication region 13a and a first cathode region 14a. The first anode region 12a and the first cathode region 14a have substantially the same depth Da. The first transfer transistor (16A, 22A and 16B) includes a first source region 16A, a first gate electrode 22A and a first drain region 16B. The first source region 16A is electrically connected to the first cathode region 14a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com