Aberration Detection Device and Optical Pickup Device Provided With Same

a detection device and pickup technology, applied in the direction of digital signal error detection/correction, instruments, recording signal processing, etc., to achieve the effect of increasing the absolute value of detection sensitivity, reducing the variation of spherical aberration error signals, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068]The following will describe an embodiment of the present invention with reference to FIGS. 1 through 13(b). The following description of the present embodiment assumes that an aberration detection device of the present invention is used for an optical pickup device included in an optical recording / reproducing apparatus which optically records / reproduces information onto / from an optical disk as an optical storage medium.

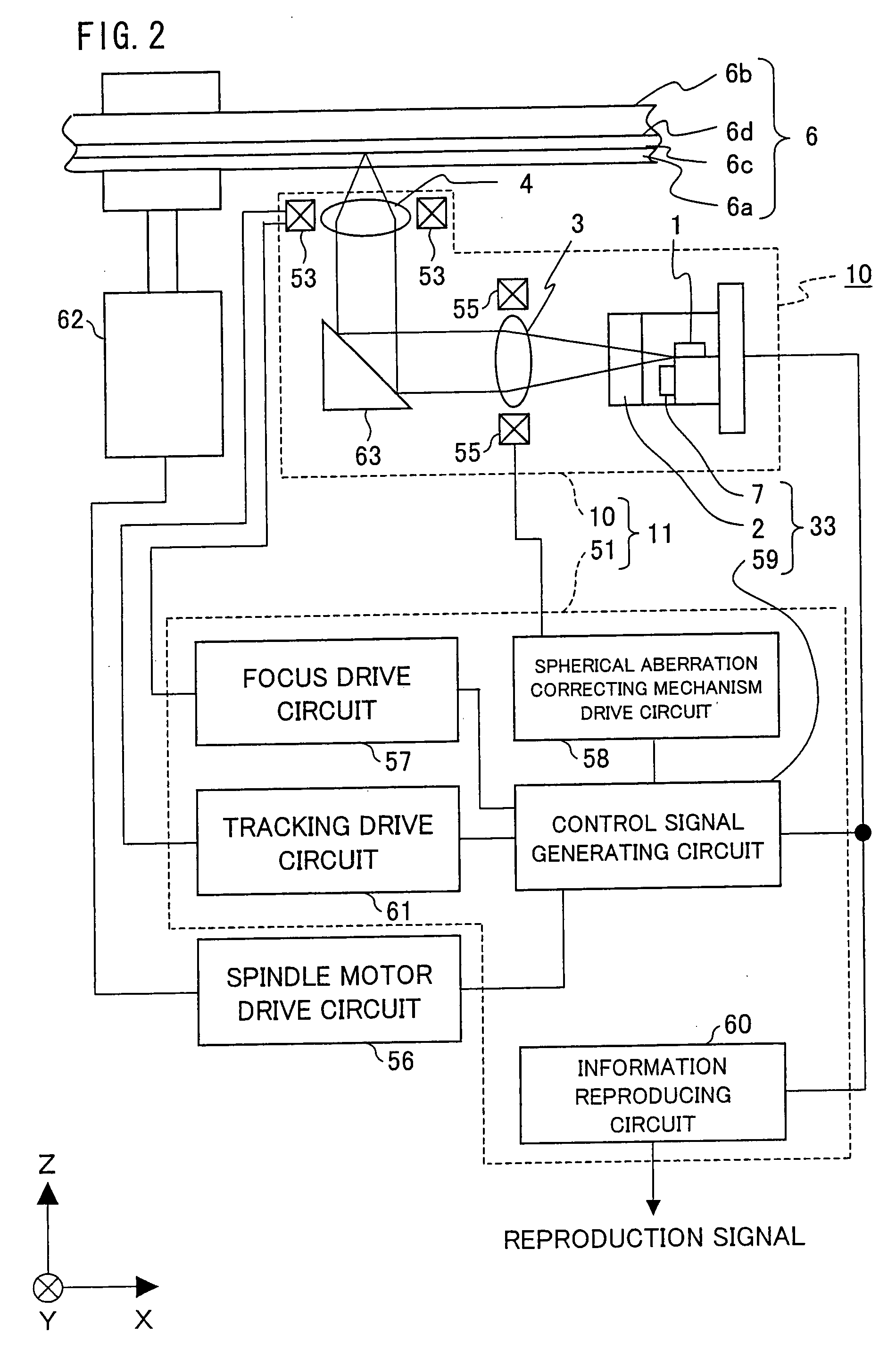

[0069]FIG. 2 is an explanatory view illustrating a general configuration of an optical recording / reproducing apparatus including an optical pickup device of the present invention. As illustrated in FIG. 2, the optical recording / reproducing apparatus of the present embodiment includes: a spindle motor 62 which rotates an optical disk (information storage medium) 6 that is an optical storage medium; a spindle motor drive circuit 56 for controlling the spindle motor 62 to be driven; and an optical pickup device 11.

[0070]The optical pickup device 11 includes: an opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com