Heat exchanger for a vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

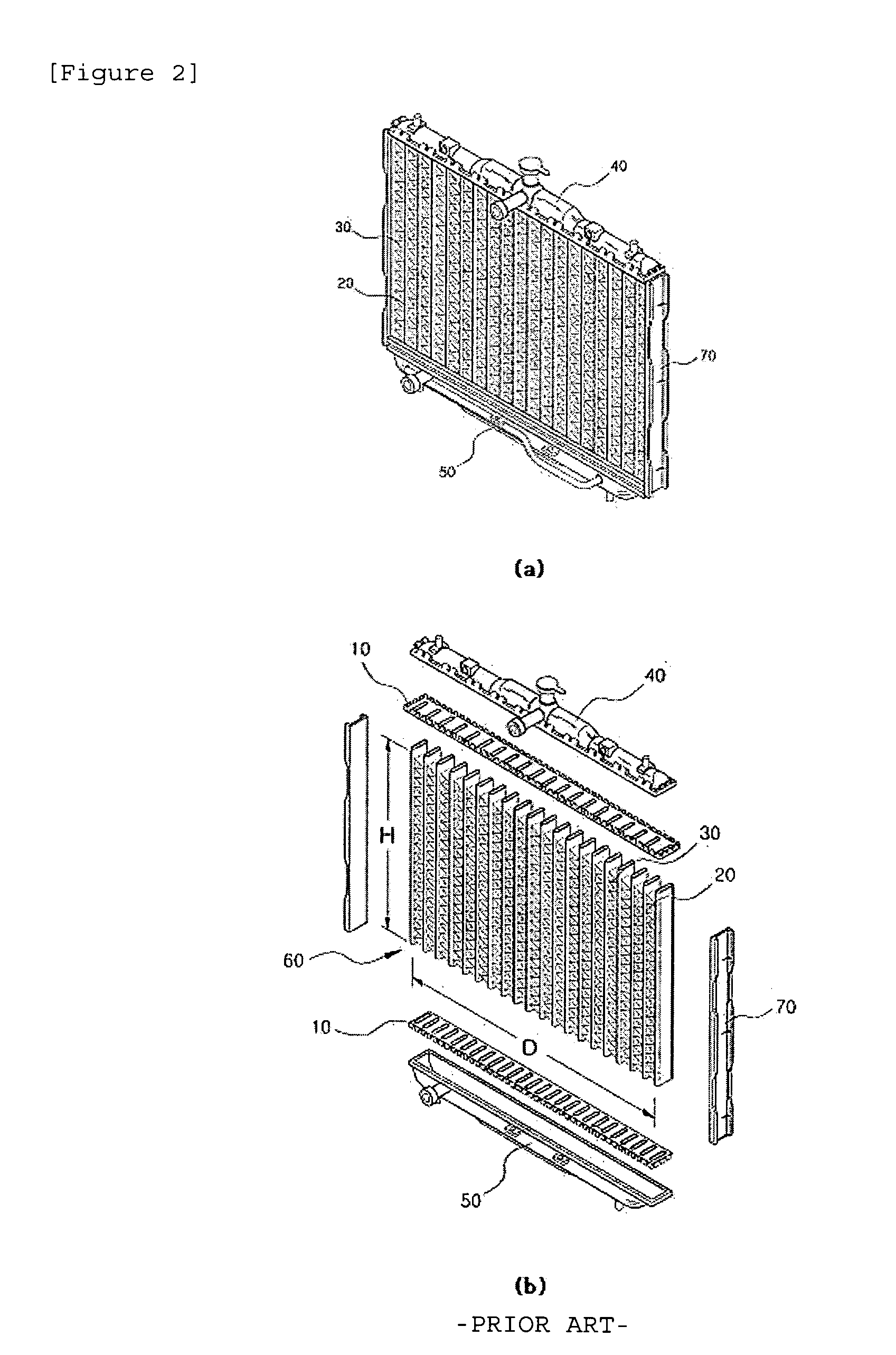

[0028]10: Header

[0029]20: Heat exchanging tube

[0030]30: Fin

[0031]40, 50: Tank

[0032]60: Core portion

[0033]70: Support

BEST MODE FOR CARRYING OUT THE INVENTION

[0034]Practical and presently preferred embodiments of the present invention are illustrative as shown in the following Examples and Comparative Examples.

[0035]However, it will be appreciated that those skilled in the art, on consideration of this disclosure, may make modifications and improvements within the spirit and scope of the present invention.

[0036]In a case of a radiator, although a heat transfer rate by air-side heat conduction occupies the largest portion of the heat transfer rate by heat transfer, variation of a heat radiation characteristic in accordance with structure modification of a component of the radiator is not so large. On the other hand, although a heat transfer rate by heat conduction in a heat exchange tube, which is a high temperature side, is low at a rate occupying in the entire heat transfer rate, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com