Hunting and Sporting Firearm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

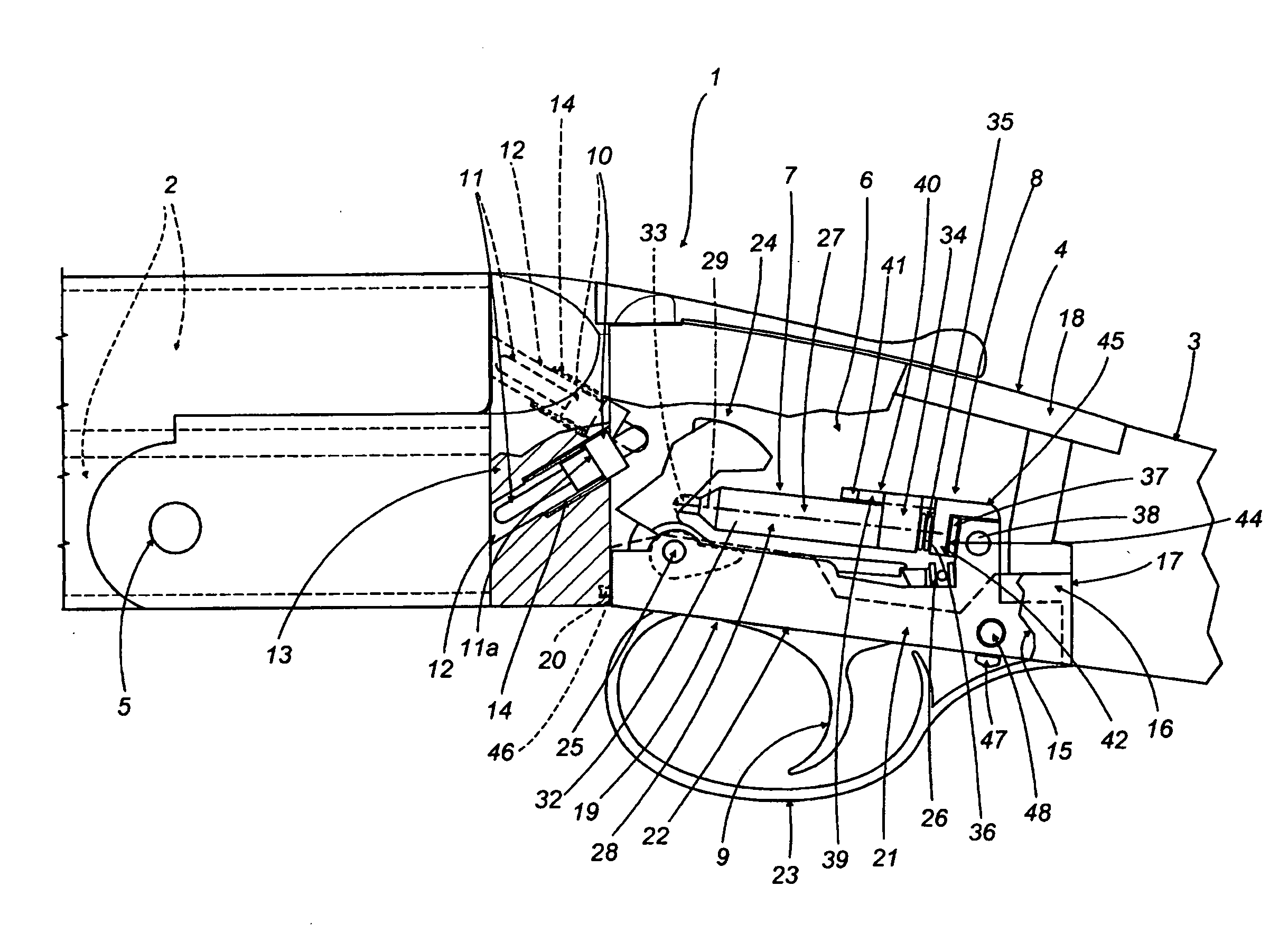

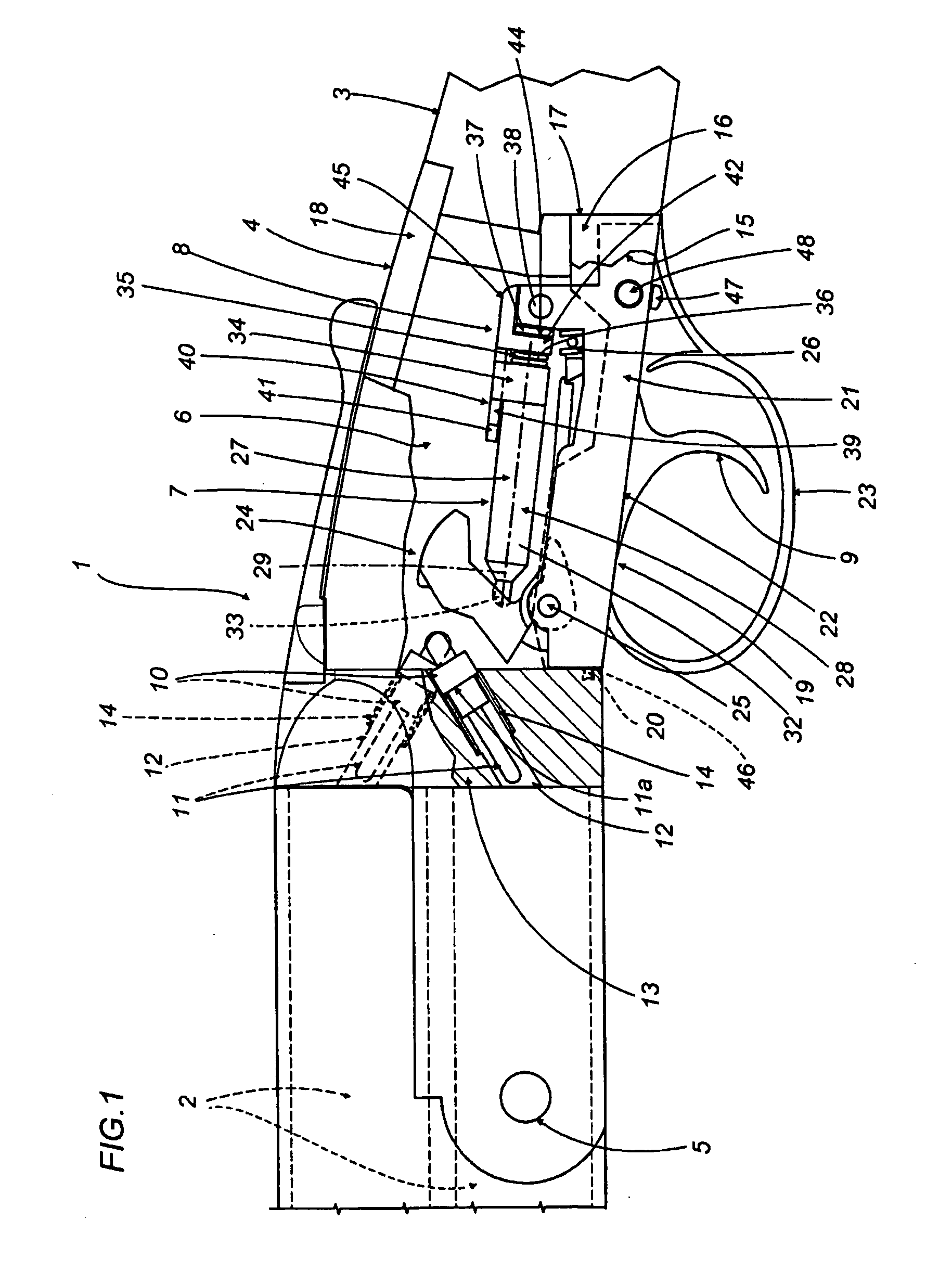

[0018]With reference to FIGS. 1 and 2, the numeral 1 denotes in its entirety an over-and-under firearm comprising a pair of barrels 2 (partially illustrated), and a stock 3 (partially illustrated), between which there is a rolling block 4 to which the barrels 2 are pivoted by means of a hinge pin 5.

[0019]The numeral 6 denotes a cavity in the rolling block 4, designed to accommodate a snap action mechanism 7 comprising, for each barrel 2, an action 8 which, upon being actuated by a trigger 9, causes a respective firing pin 10 associated with each barrel 2 to impact the case of a cartridge (not illustrated).

[0020]Each firing pin 10 consists of a substantially cylindrical rod 11 having a rim 11a at an intermediate position of it and housed in a through hole 12 made in a transversal wall 13 separating the cavity 6 from the respective barrel 2. Positioned around each firing pin 10 and abutting against the rim 11a there is a helical spring 14 for retracting the firing pin 10 into the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com