Cavity Wall System

a cavity wall and wall technology, applied in the direction of walls, coverings/linings, constructions, etc., can solve the problems of requiring costly corrective maintenance, affecting and causing new difficulties in the field of building systems and methods of construction, so as to facilitate the drying of the underlying wall structure, reduce wind-induced movement of the membrane, and enhance the thermal insulation characteristics of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

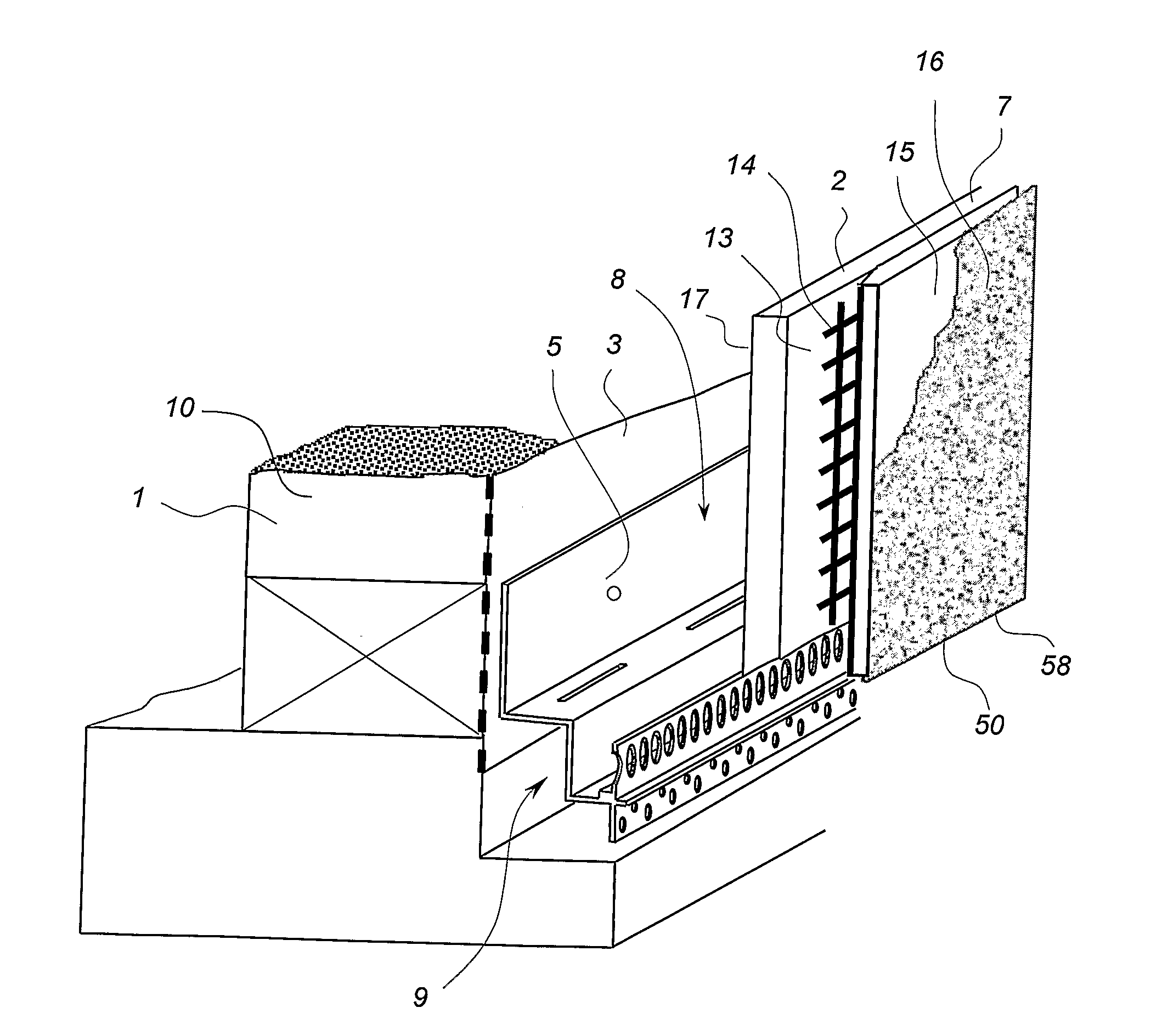

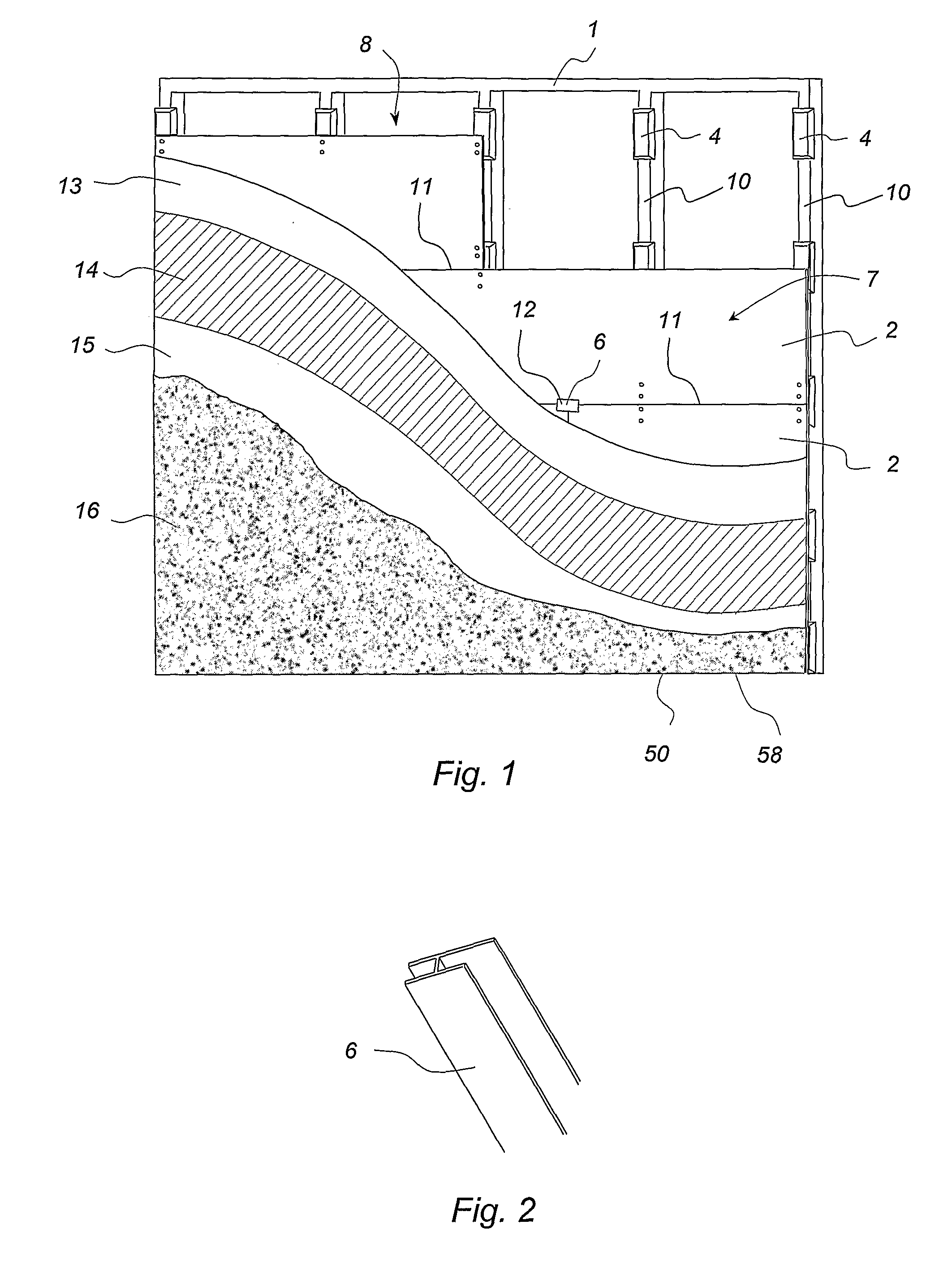

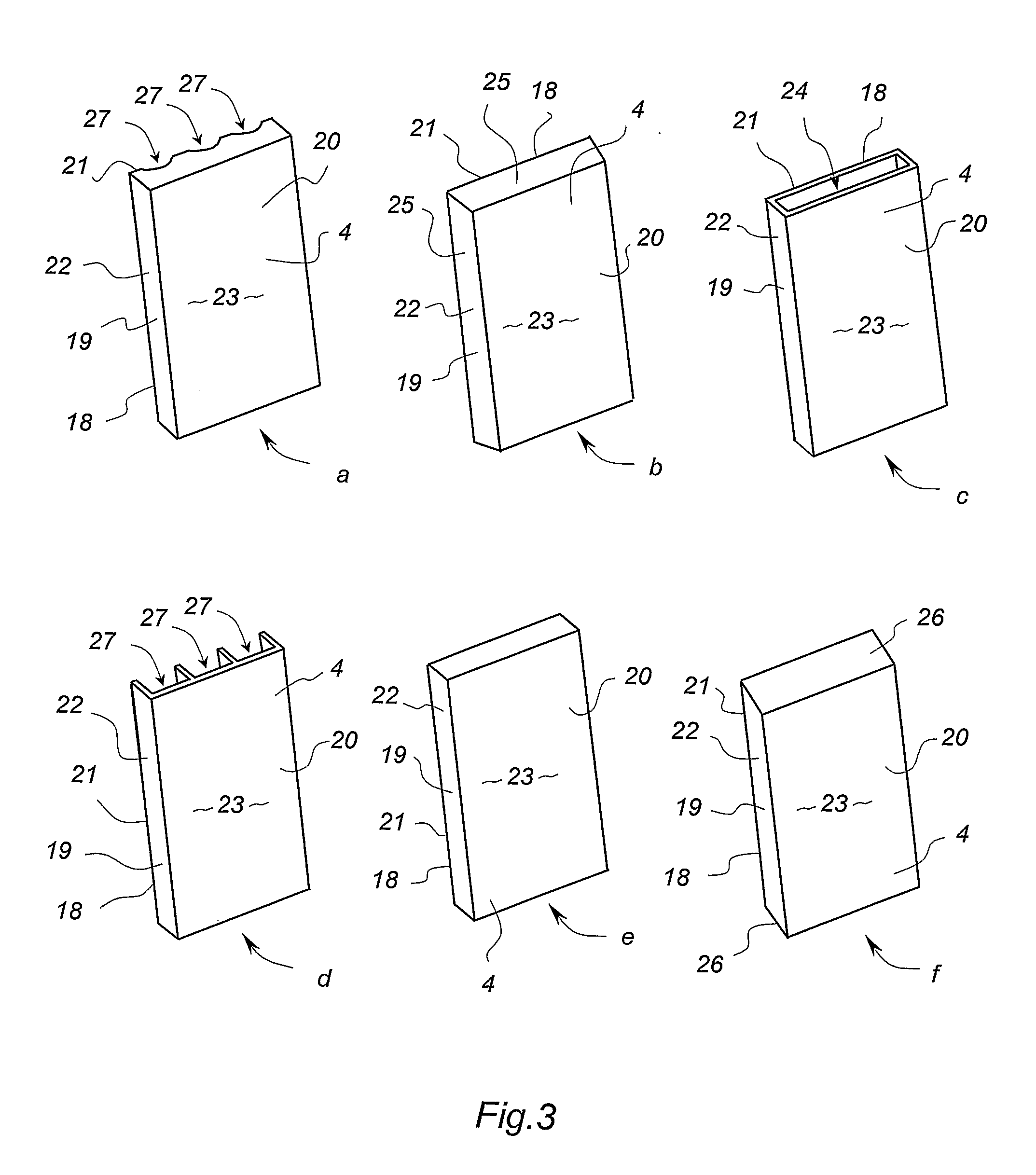

Embodiment Construction

[0082]Referring to the drawings, the invention provides a cavity wall system including a wall structure 1 and a plurality of outer wall cladding panels 2. In the preferred embodiment, the wall structure is a building frame with its outer side substantially covered by moisture control means in the form of a pliable building membrane 3 defining a moisture control plane. Also preferably, the cladding panels 2 are formed substantially from fibre cement sheets, or other materials such as EPS, of sufficient strength and thickness. The system further includes a plurality of discrete mounting elements including mounting members 4, termination members or starter strips 5 and off-stud joiners 6. These are attached over the building membrane to mount the fibre cement cladding panels a predetermined distance away from the building membrane, forming a substantially flat exterior wall surface 7 and a substantially uninterrupted internal wall cavity 8 between the cladding panels and the building m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com