Grain orientation control through hot pressing techniques

a technology of orientation control and hot pressing, applied in the manufacture of brushes, current collectors, dynamo-electric components, etc., can solve the problems of durability issues, design limitations, structural features and properties/performance, and the inability to manufacture brushes according to conventional processing techniques/methodologies, so as to improve the density of work pieces, enhance the durability of workpieces, and improve the effect of functional properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

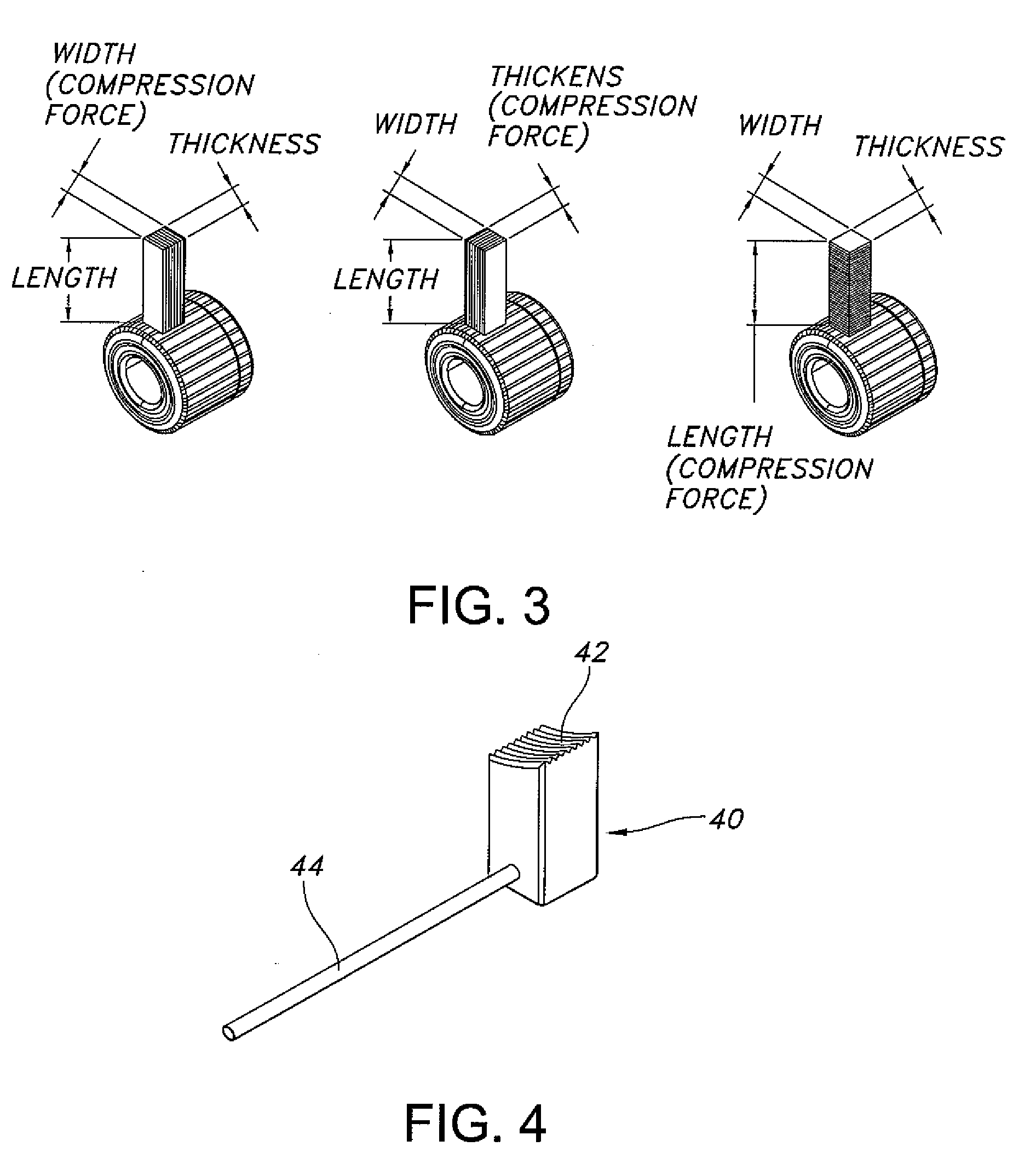

[0024] Systems and methods for manufacture of electrical components, e.g., brushes, and advantageous electrical components, e.g., brushes / brush assemblies, are provided herein. The disclosed systems, methods and articles of manufacture advantageously control grain orientation in the manufacturing process such that advantageous physical and functional properties are imparted thereto. The disclosed systems and methods utilize hot pressing techniques to provide enhanced properties and / or functionalities to brushes and other electrical components, e.g., carbon and / or copper-containing systems, and find wide ranging applications, including the manufacture and / or fabrication of pressed-to-size brushes.

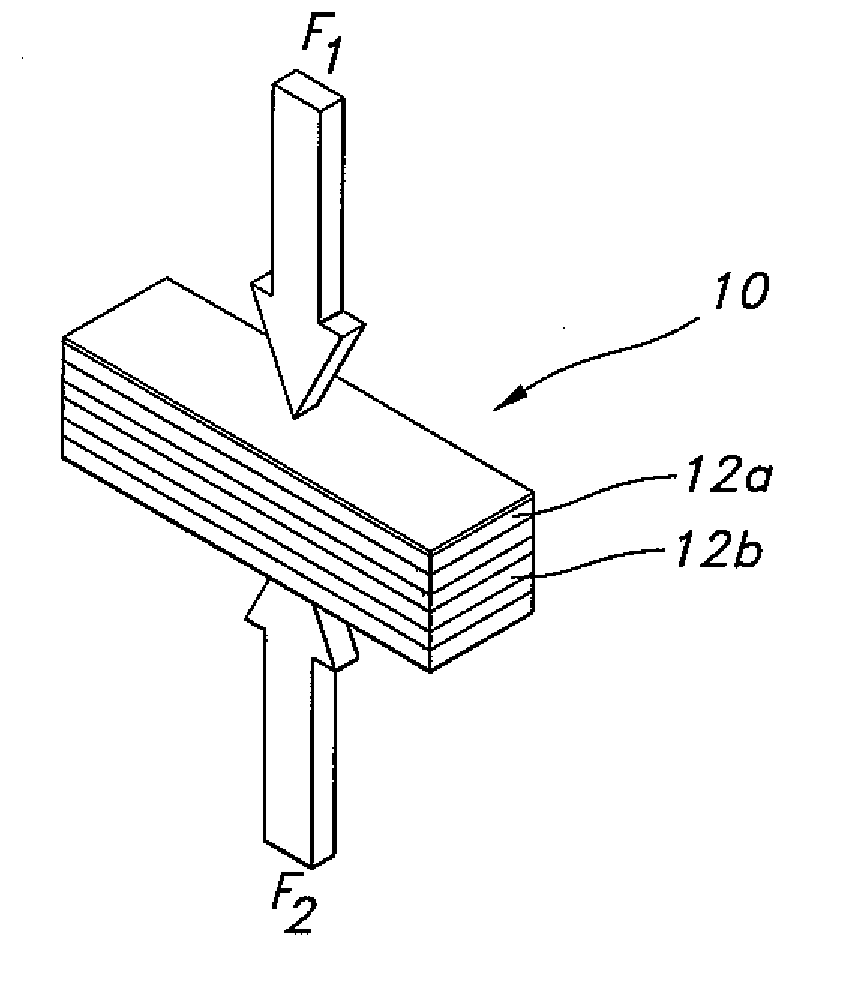

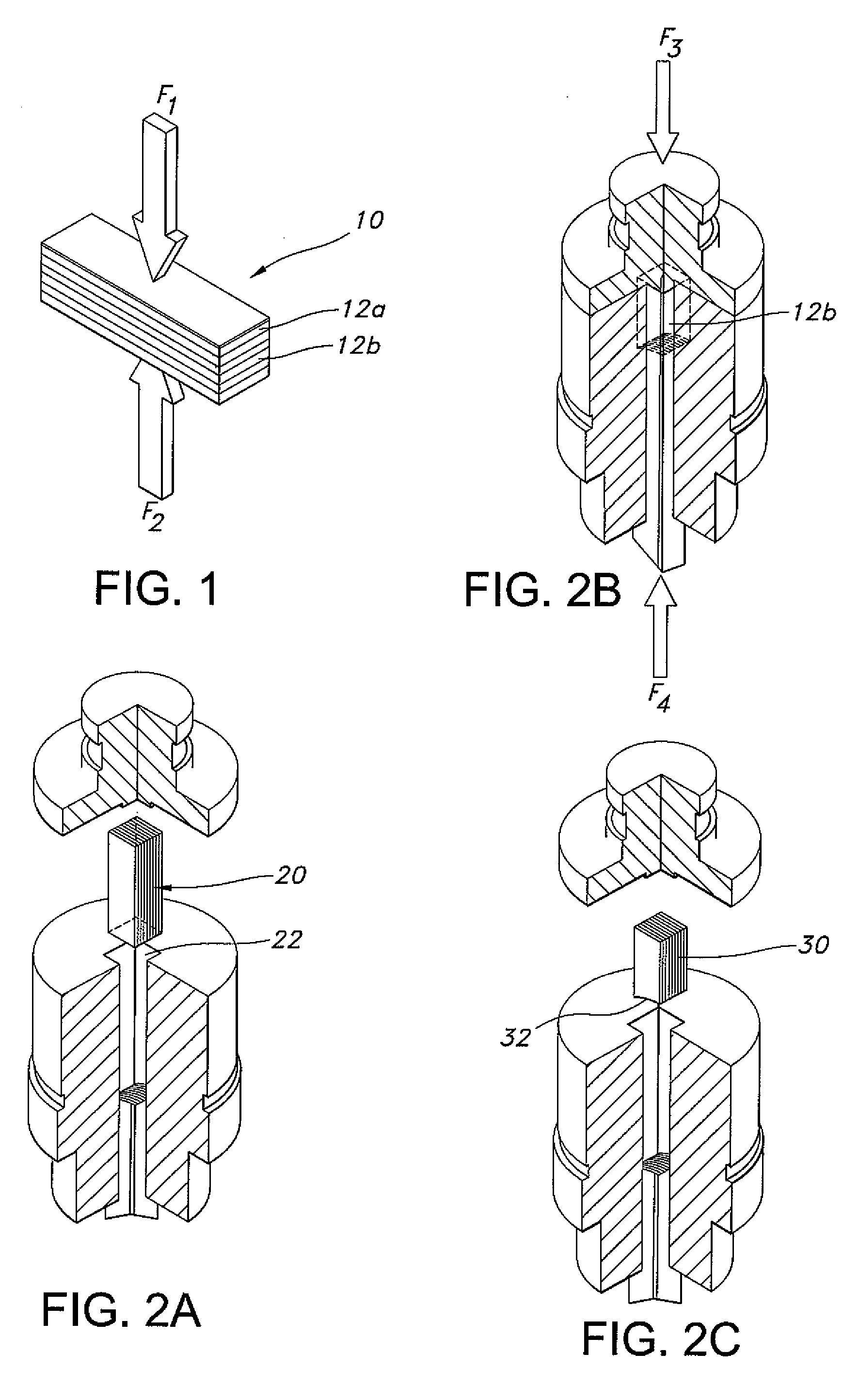

[0025] According to exemplary embodiments of the present disclosure, a powder mixture is initially pressed in a conventional manner to form an intermediate work product. With reference to FIG. 1, a conventional pressing step is schematically depicted. A substantially axial compression force...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com