Heat pump cycle device

a cycle device and heat pump technology, applied in heat pumps, indirect heat exchangers, lighting and heating apparatus, etc., can solve problems such as fog on the windshield of vehicles, and achieve the effect of effective improvement of cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

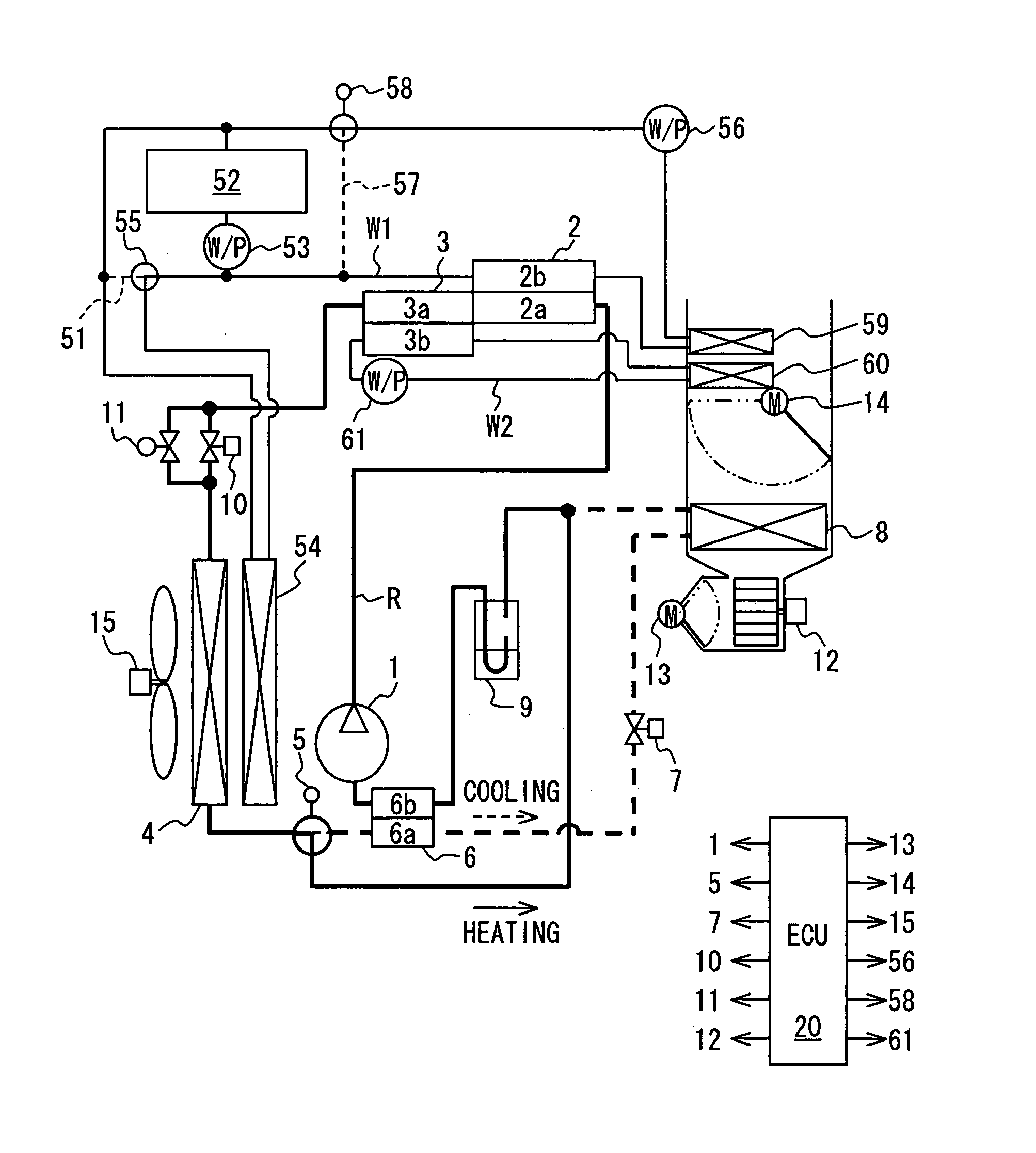

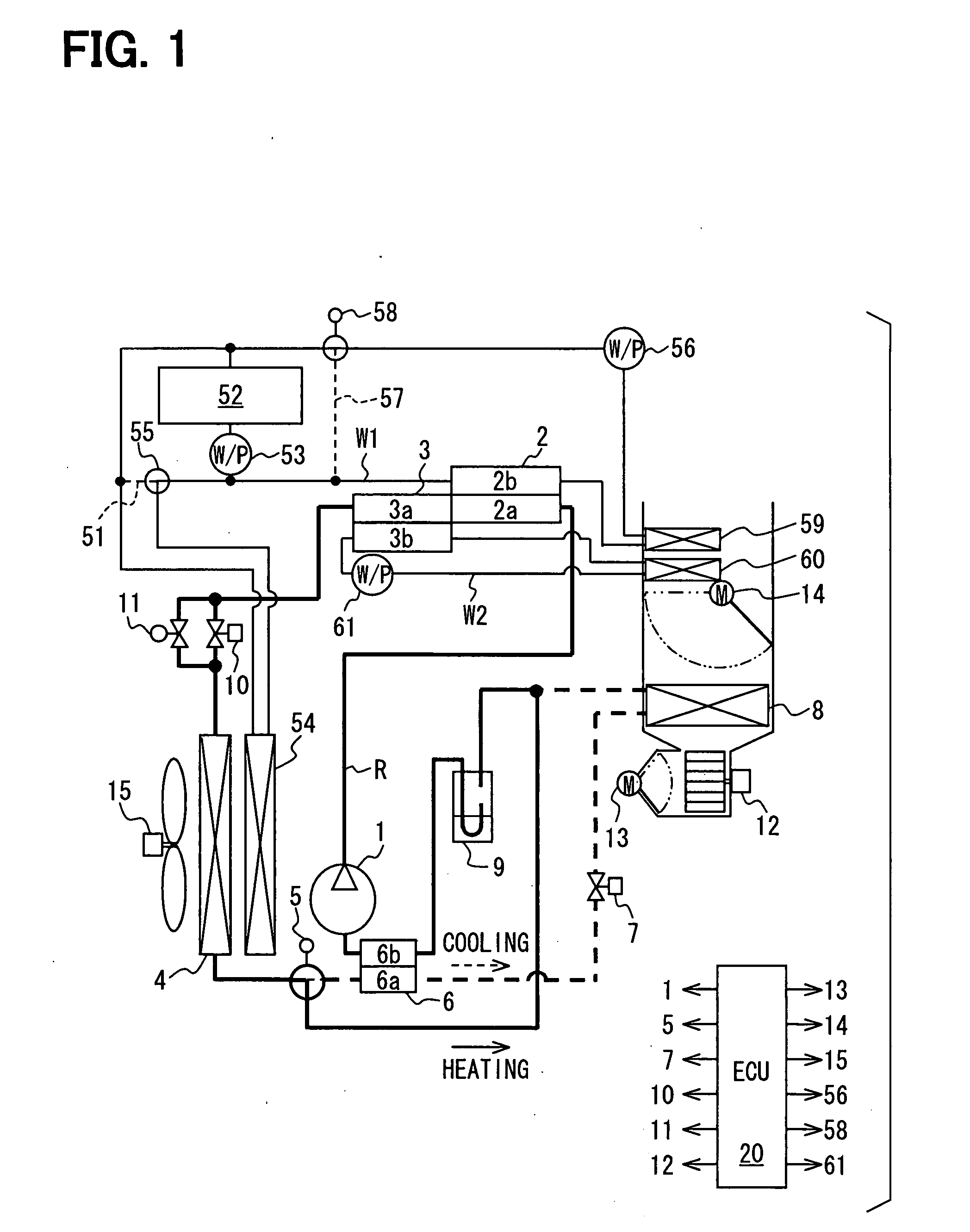

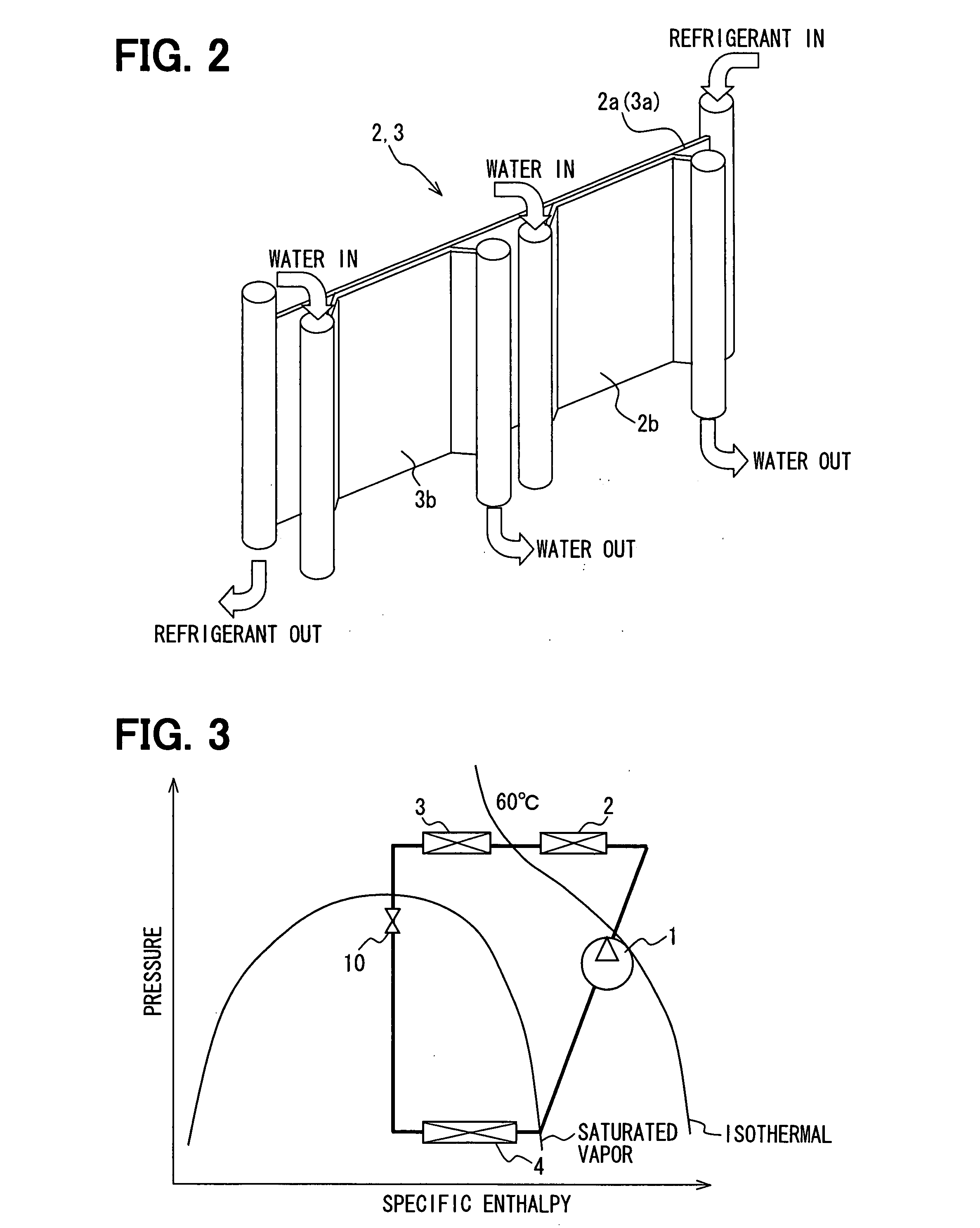

[0022] A first embodiment of the present invention will be now described with reference to FIGS. 1 to 3. In this embodiment, a heat pump cycle device of the present invention is typically used for an air conditioner for a vehicle, and is provided to improve a cycle efficiency while having an auxiliary heating function.

[0023] As shown in FIG. 1, the heat pump cycle device includes a refrigerant cycle R in which refrigerant circulates, a first water circuit W1 in which engine-cooling water as a first fluid circulates, and a second water circuit W2 in which water as a second fluid circulates. In this embodiment, the first water circuit W1 and the second water circuit W2 are formed independently from each other. However, the first water circuit W1 and the second water circuit W2 may be partially joined with each other.

[0024] First, the refrigerant cycle R will be described. In the refrigerant cycle R of FIG. 1, a compressor 1 draws and compresses low-pressure side refrigerant, and dis...

second embodiment

[0065]FIG. 4 is a schematic diagram showing a heat pump cycle device according to a second embodiment of the present invention. In the second embodiment, a third heat source 62 is additionally provided in the second water circuit W2, compared with the above-described first embodiment.

[0066] The third heat source 62 is an auxiliary machine (heat generating unit) such as an inverter and an electronic member of a hybrid vehicle, which generates heat when being operated. The auxiliary machine is located in the second water circuit W2 to recover exhaust heat. Furthermore, an auxiliary radiator 63 may be located in the second water circuit W2. In this embodiment, because the third heat source 62 is located in the second water circuit W2 in which the second fluid (water) circulates, the air heating efficiency of the second water heater 60 in the second water circuit W2 can be further improved.

[0067] The heat quantity supplied from the second heat source (e.g., engine) 52 is normally larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com