Exhaust Articles for Internal Combustion Engines

a technology of exhaust articles and internal combustion engines, applied in the direction of physical/chemical process catalysts, metal/metal-oxide/metal-hydroxide catalysts, separation processes, etc., can solve the problems of dampening out the normal air/fuel cycling used in engine controller strategies, and reducing the efficiency of the catalytic converter. , to achieve the effect of reducing the cost of catalysts, and reducing the cost of catalys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Comparative Nonmethane Hydrocarbon and Nitrogen Oxide Abatement Performance

Exhaust System A

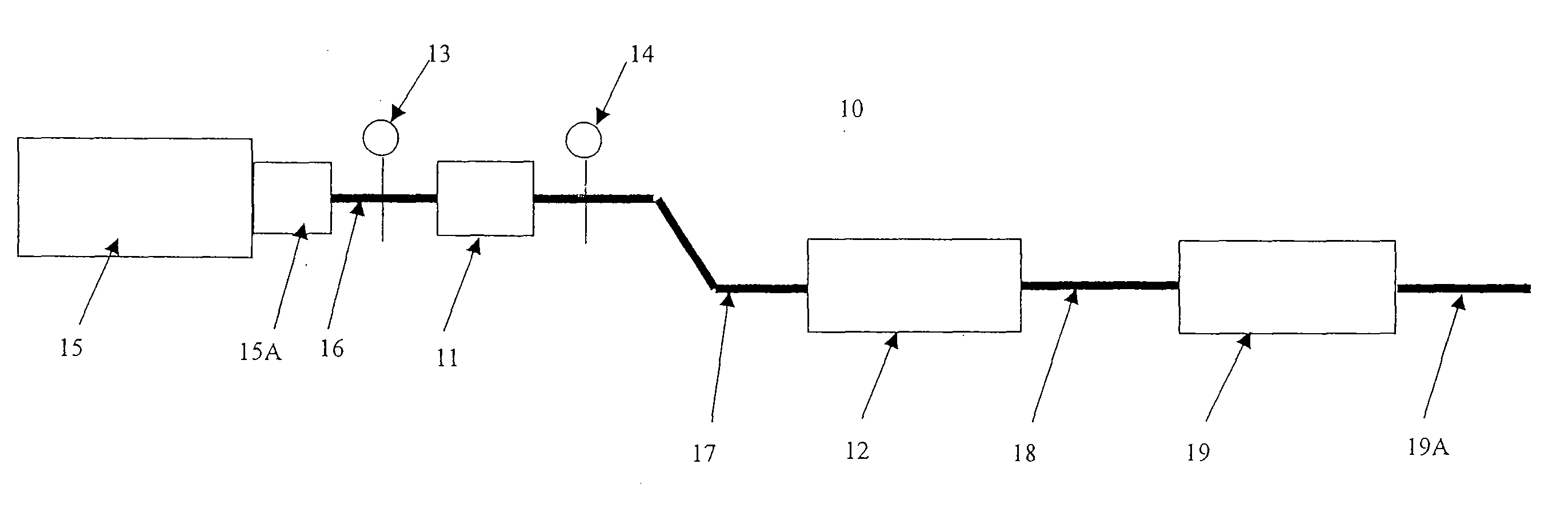

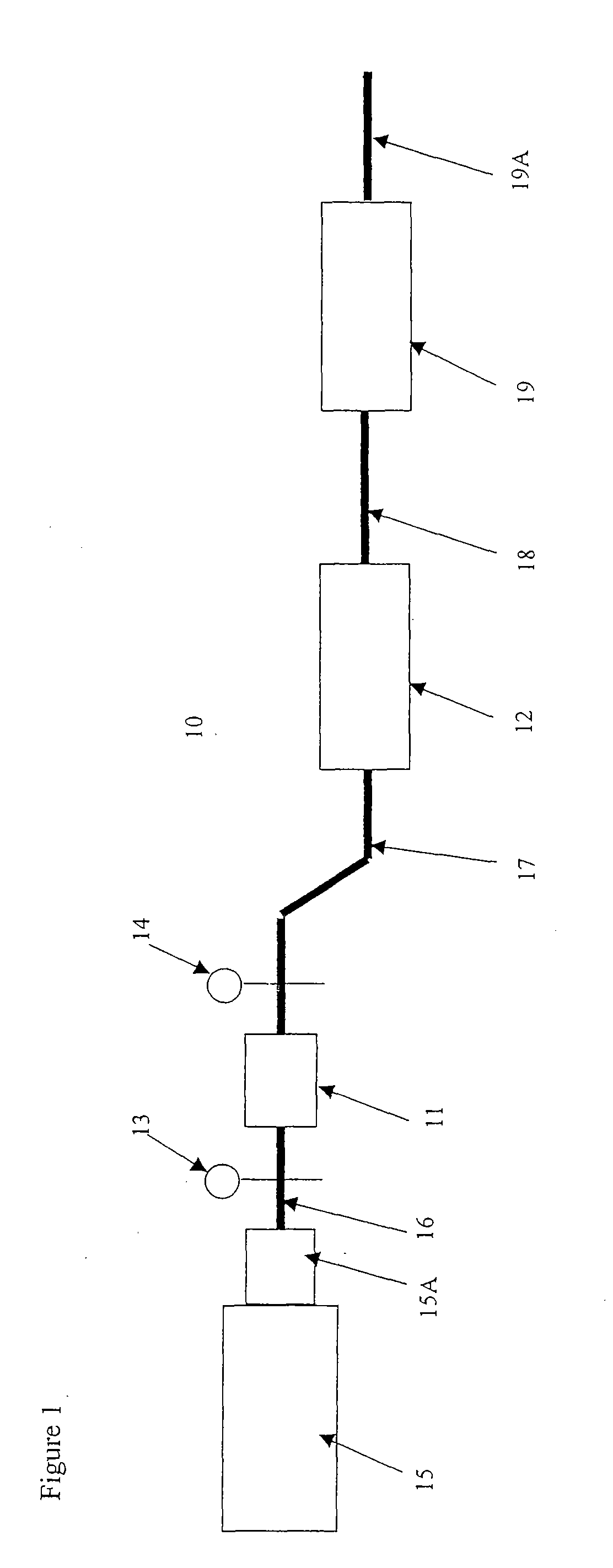

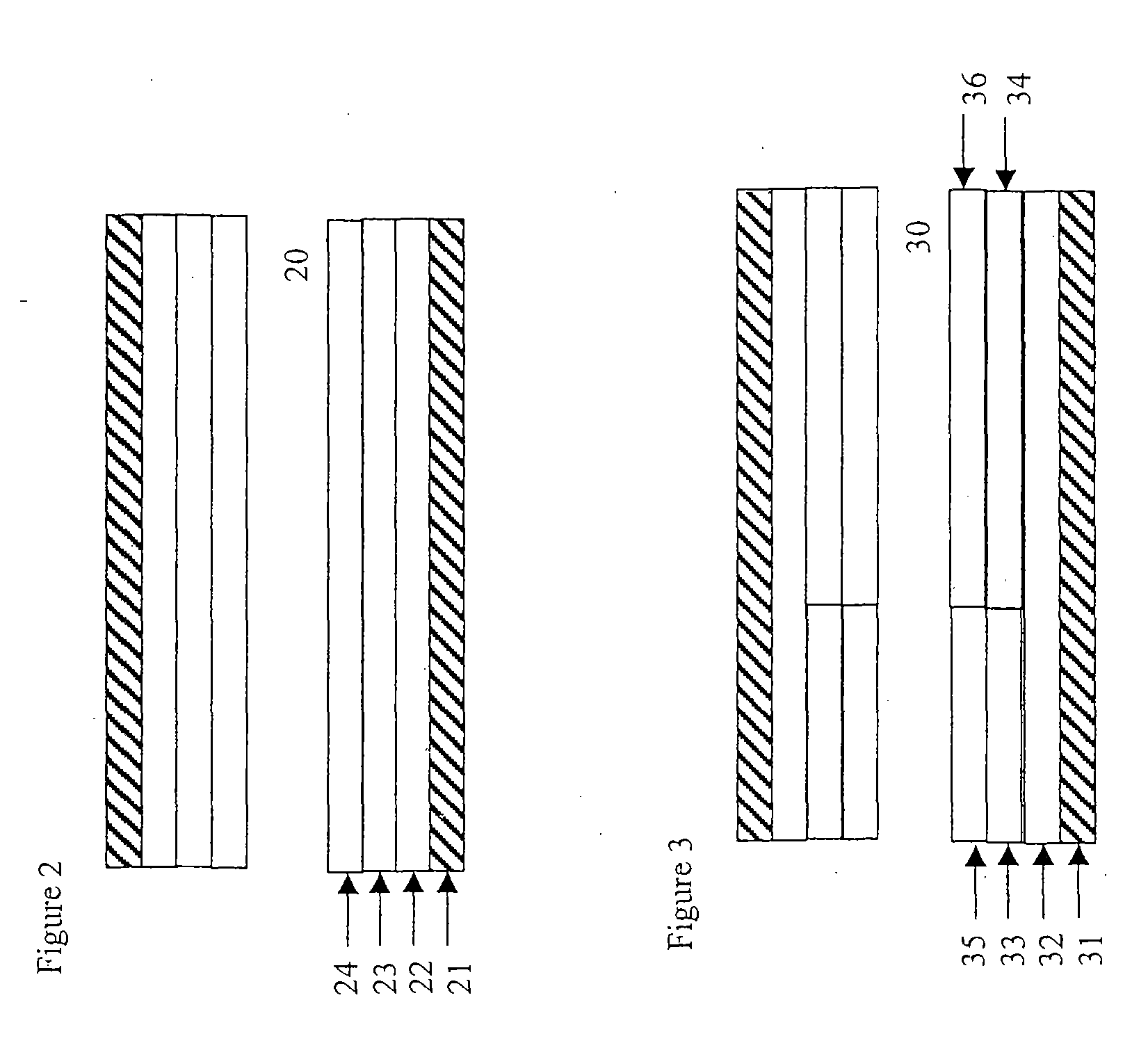

[0134] Exhaust system A contained two catalysts of the invention including a preferred multi-zoned layered catalyst (as seen in FIG. 3) having a base metal undercoat as a close-coupled catalyst and a preferred layered catalyst (also with a base metal undercoat) as a downstream underbody catalyst (as seen in FIG. 2).

[0135] The close coupled catalyst was prepared by coating an oval-shaped cordierite honeycomb carrier having a total volume of 55 in3 [dimensions 3.15 in (X)×4.75 (Y)×4.3 in (Z)] according to the methods described above. The upstream section of the carrier had a volume of 19.2 in3. The upstream section contained a formulation having a ratio of Pt / Pd / Rh of 1:20:1 with a total platinum group metal loading of 110 g / ft3. The first upstream zone (supported on the base metal undercoat) with a washcoat loading of 1.27 g / in3 contained platinum and palladium components. The second upstre...

example 2

Performance of a Multi-Zoned Layered Catalyst of the Invention with Differing Concentrations of Undercoat Oxygen Storage Component

[0142] Multi-zoned layered catalyst as described for the close-coupled catalyst of Exhaust System A of Example 1 were prepared. One catalyst A1 contained a base metal undercoat with a ceria-zirconia composite of 35% by weight ceria and a loading of 0.5 g / in3. A second catalyst A2 contained a base metal undercoat with a ceria-zirconia composite of 45% by weight ceria and a loading of 1.0 g / in3 (i.e., the ceria was increased by 80% in catalyst A2). After 50k equivalent aging, the total hydrocarbon (THC) and NOx were evaluated using the FTP 1975 with a 4.6 L engine vehicle. The THC and NOx collected in each bag is displayed in Table 1.

TABLE 1THCTHCNOxNOxA1A2A1A2Bag 10.160.1510.0710.074Bag 20.0120.0110.0030.002Bag 30.0260.0270.0230.045FTP0.0460.0440.0240.029

[0143] The data obtained for the two catalysts with different oxygen storage capacities in the under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com