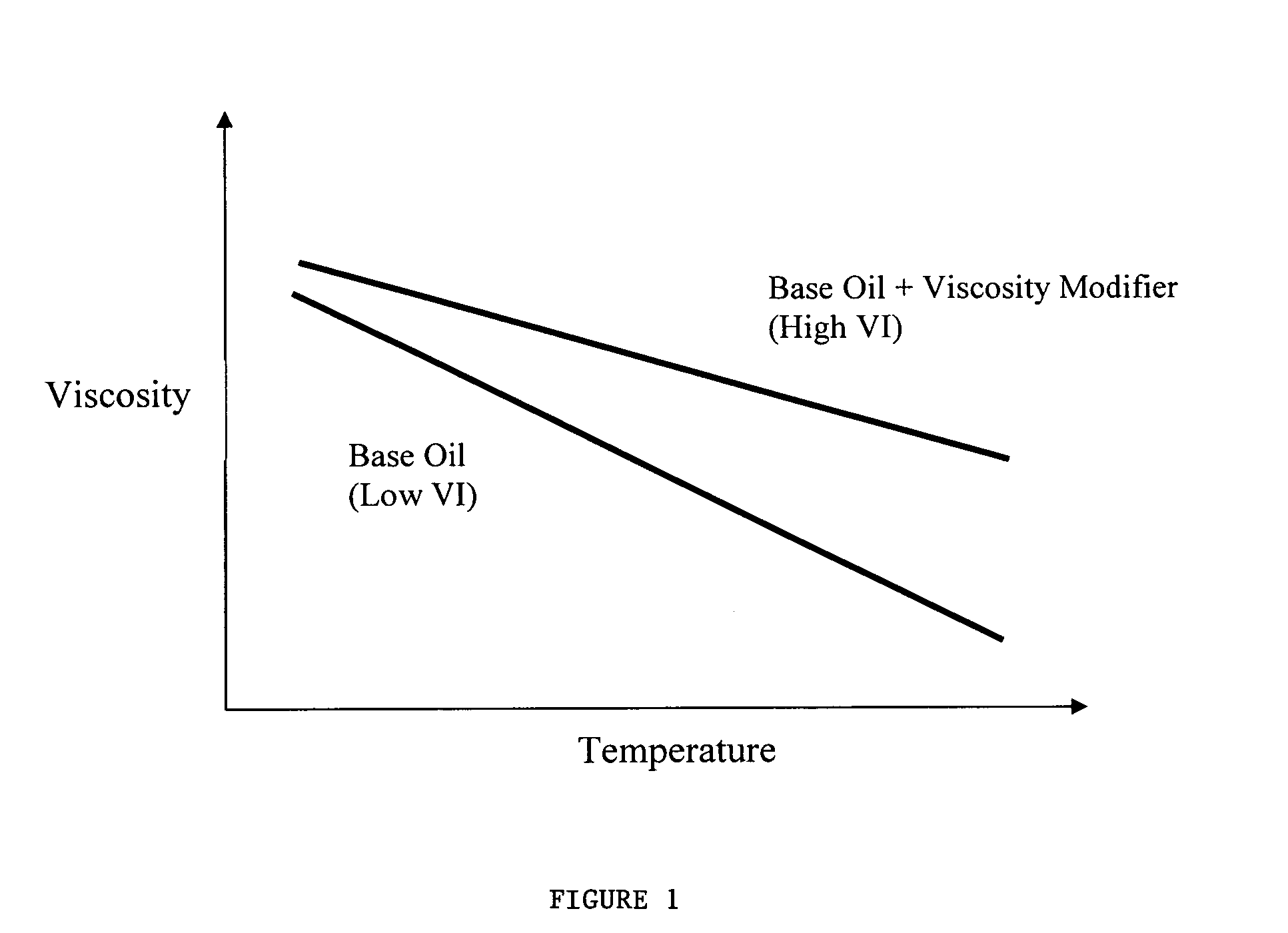

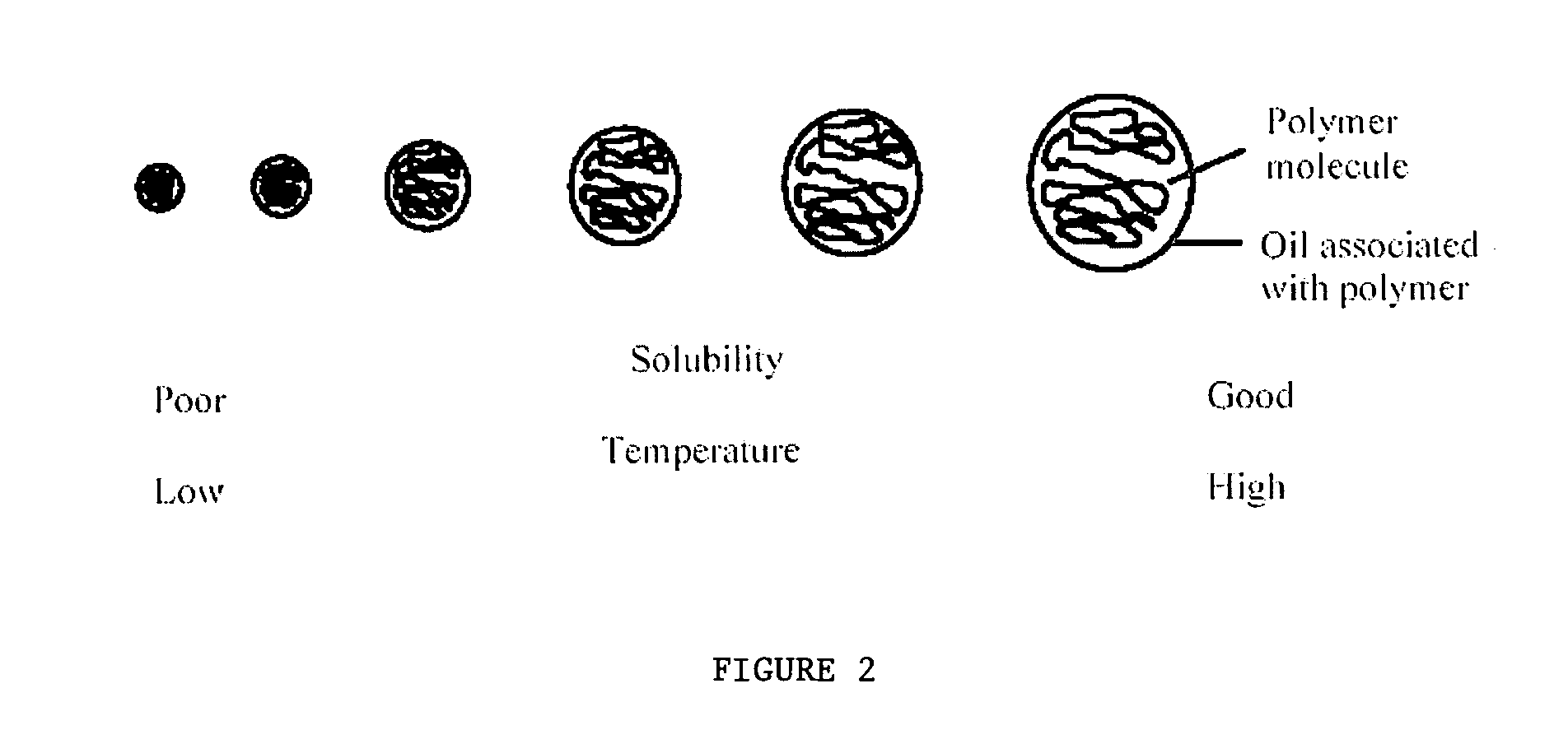

Use of nanomaterials as effective viscosity modifiers in lubricating fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Automatic Transmission Fluids and Viscosity Data

[0111]

ATFABCDE*From ConcentratePaste APaste BPaste CPaste DN / AKinematic viscosity at7.5519.6810.837.487.15100° C., cStKinematic viscosity at28.4429.3228.7727.8533.6740° C., cStViscosity Index254634395257183

*E is an off-the-shelf regular commercial ATF (MERCON V).

example 2

Engine Oil

[0112]

ProductConventionalNanoparticle-containingEngine OilEngine oilCompositionValvoline90% DURABLEND 5W-30DURABLEND 5W-309% DURASYN 1621% GraphiteProcessBulk graphite is pulverized, andmilled in DURASYN 162 to obtaina paste. The paste is added toDURABLEND 5W-30Viscosity10.6610.90@ 100° C.Viscosity61.1454.34@ 40° C.Viscosity166197Index

example 3

Shock Absorber Oil

[0113]

ProductConventionalNanoparticle-containingShock OilShock oilCompositionVISTA LPA62.4077.70210LUBRIZOL36.8720.667720CLUBRIZOL0.300.305186BTricresyl0.220.22phosphateF-655C0.20defoamerBlue Dye0.010.01Graphite1.11ProcessGraphite obtained as powders(UCAR), and milled in VISTALPA 210 / LZ 7720C to obtain aconcentrate. Then the otheringredients are added tomake the final formulationViscosity8.977.77@ 100° C.Viscosity29.7512.45@ 40° C.Viscosity307732Index

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com