Phase change sensor

a phase change sensor and sensor technology, applied in the direction of instruments, biomass after-treatment, analysis using chemical indicators, etc., can solve the problems of unresolved noise problems along the connecting wire, the replacement of the probe in some spm designs may take many minutes, and the exterior transfer and processing circuit occupies a relatively large space, so as to achieve enhanced device selectivity, high-sensitivity and selective sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific embodiments

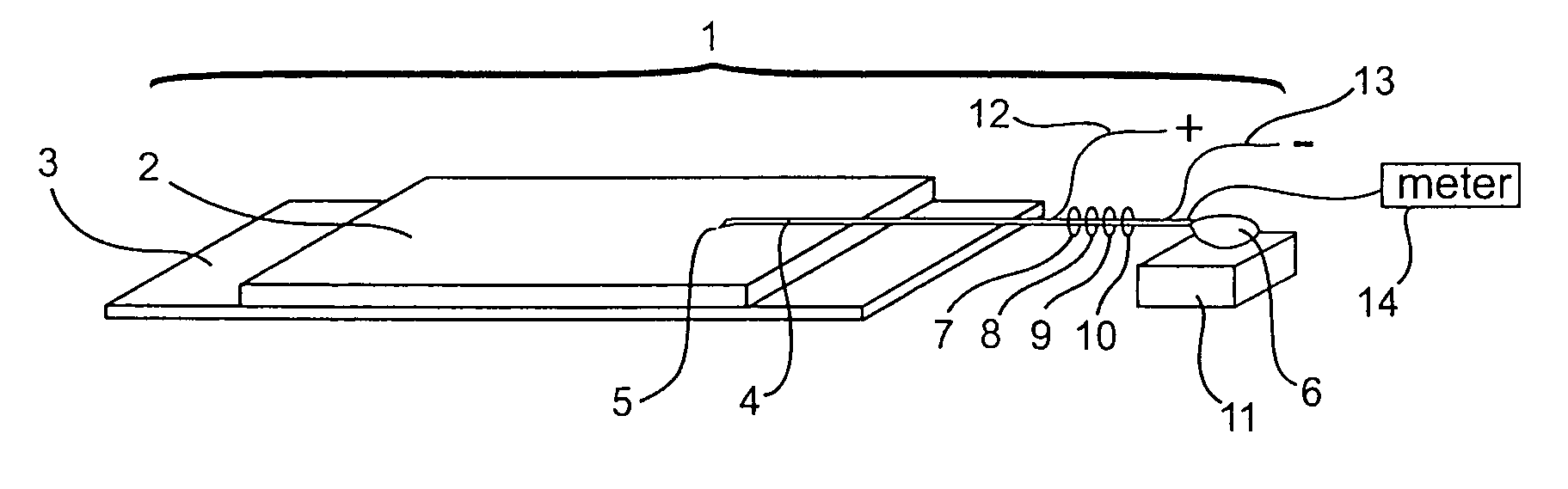

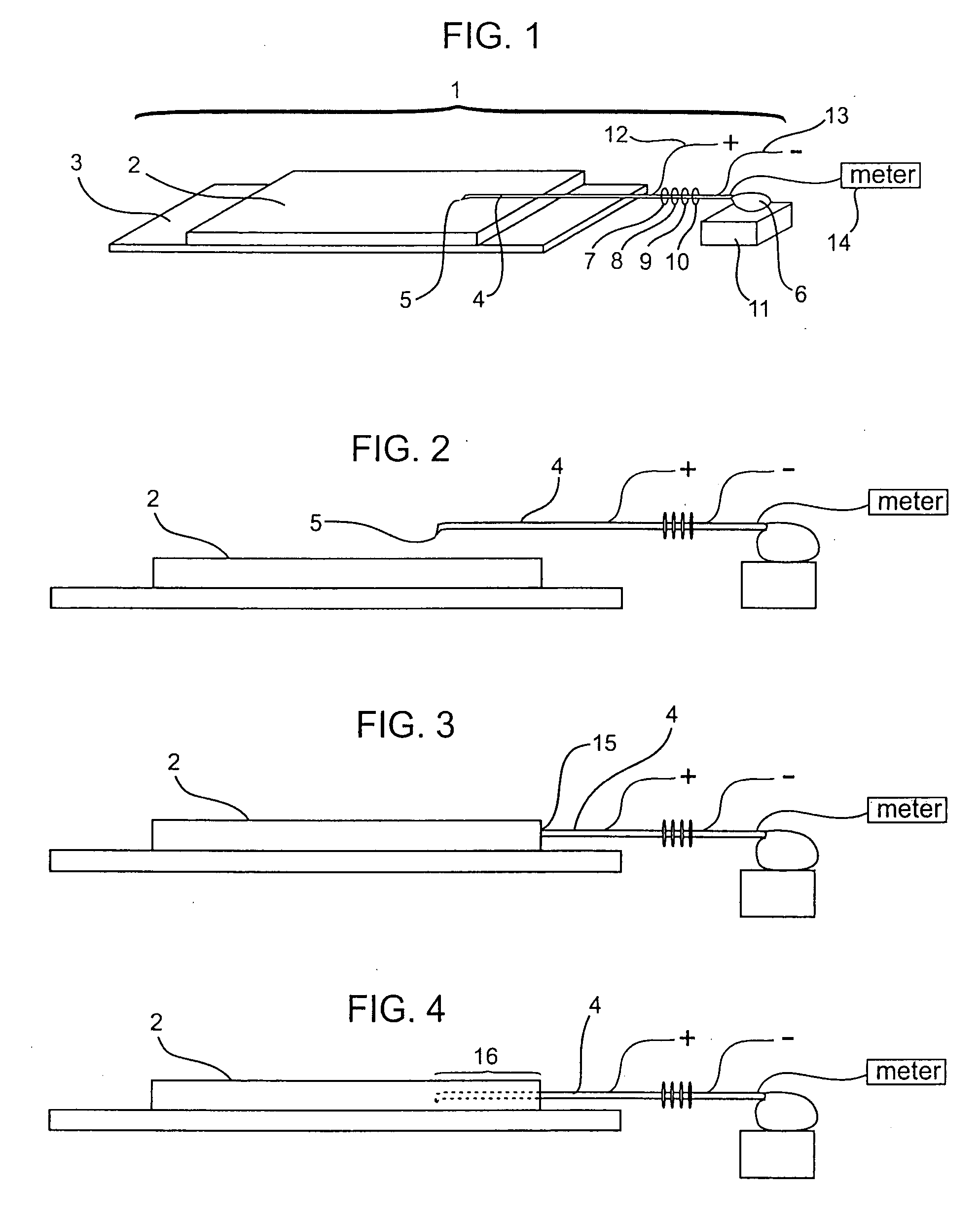

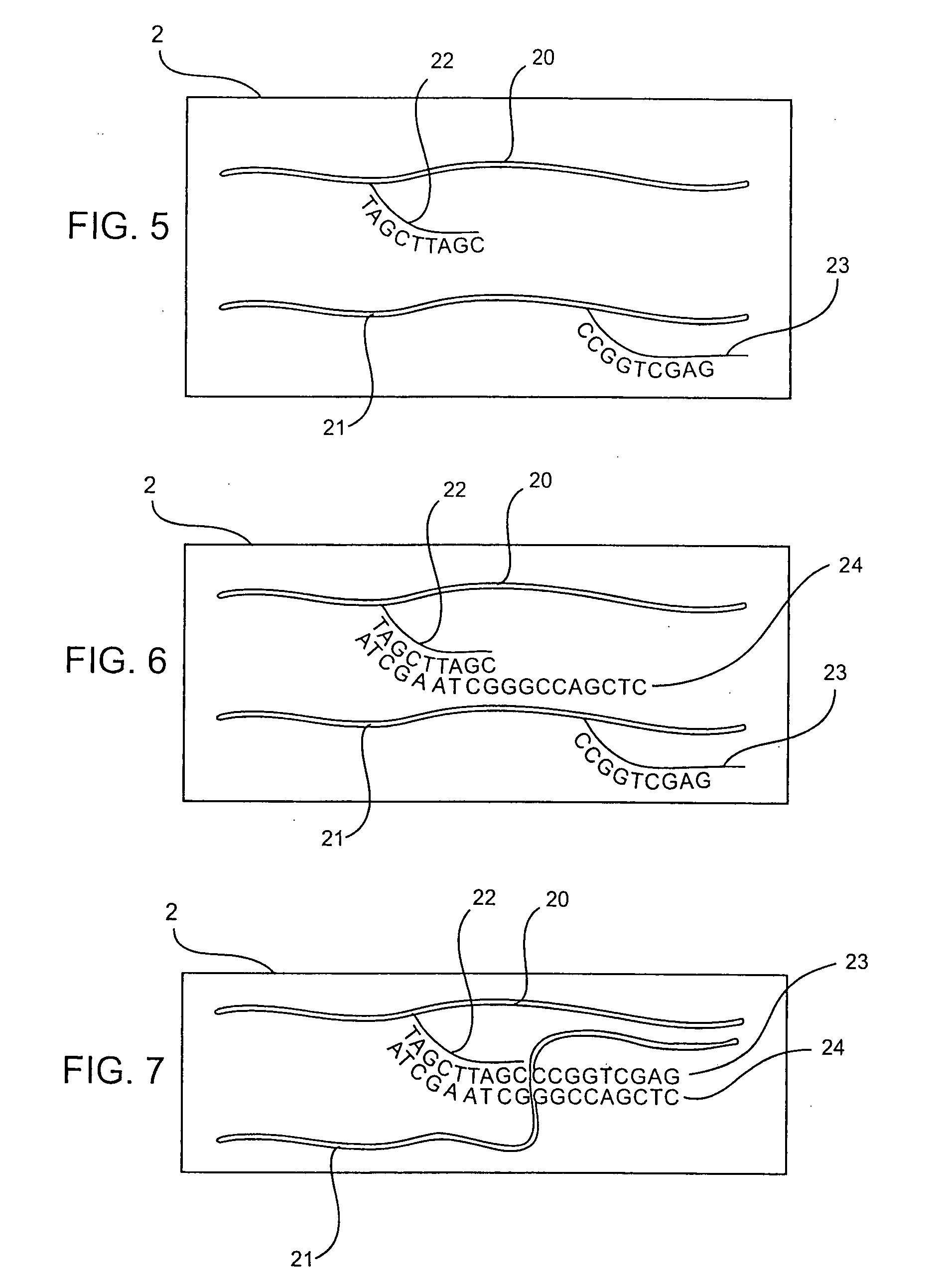

[0088]FIG. 1 shows a perspective, schematic view of an embodiment of a sensor device 1 of the invention. The device 1 is comprised of a sensor material 2 connected, secured, attached or anchored in place in some manner such as to a substrate 3. An arm 4 is positioned over the sensor material 2 and an end 5 of the arm 4 is positioned very close to a surface of the sensor material 2 such as 1 mm or less, or 0.1 mm or less or 1 micrometer or less. Thus, when the sensor material 2 expands it moves the end 5 of the arm 4. Conventional microcantilever sensor devices are disclosed in U.S. Pat. No. 6,523,392 issued Feb. 25, 2003 and U.S. Patent Publication No. 2003 / 0010097 published Jan. 16, 2003. These designs may be changed to include sensor material 2 of the present invention.

[0089] The arm 4 may be comprised of a suitable material such as silicon or variation or analog thereof such as silicon nitride which may be heated and drawn into a thin strand. The arm 4 may be formed from and int...

example 1

Hydrogel Polymer

[0132] Polymer is prepared comprising hydroxypropyl acrylate having a MW of between 200,000 and 500,000 daltons. The resulting polymer is washed with ethyl actetate to remove residual monomer and taken up in a 1:1 mixture of ethyl acetate: tetrahydrofuran at 25% solids.

[0133] To a 3 gram polymer solids sample is added 0.2% w / w PFAZ 233 polyfunctional crosslinking agent (BAYER) and cast onto glass petri dishes. The polymer is allowed to crosslink and dried at 90° C. for 12 hours.

[0134] The water uptake of the polymer is measured at varying osmolalities and seen to be highly responsive to changes in osmotic properties. Further details regarding hydrogel polymers are provided below in Example 8.

example 2

Osmolality Sensor

[0135] Polymer solution as above is diluted to 10% solids and a 1.0 mm thick glass chip is dip coated with the solution and dried. The resulting polymer film is approximately 25 microns thick. A piezoresistive microcantilever (Veeco) (and its electrical contacts including solder wires) is dip coated with a 10% solids solution of 2 part epoxy twice and dried at 90□C. The cantilver is then mounted proximate to the glass chip such that the cantilever is just touching the surface of the polymer. The resulting assembly is dip coated a second time to embed the cantilever.

[0136] The sensor responds predictably to changes in osmolality in the range of interest for human saliva (50-200 mOsmol). Further details on such a sensor are provided below in Example 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmolarity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com