Laser-ultrasonic detection of subsurface defects in processed metals

a technology of subsurface defects and laser ultrasonic detection, which is applied in the field of metal processing and alloys, can solve the problems of metal processing defects that may occur within the processed region of metals, such as voids, pores, disbonds and cracks, and are not practical for in-line us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

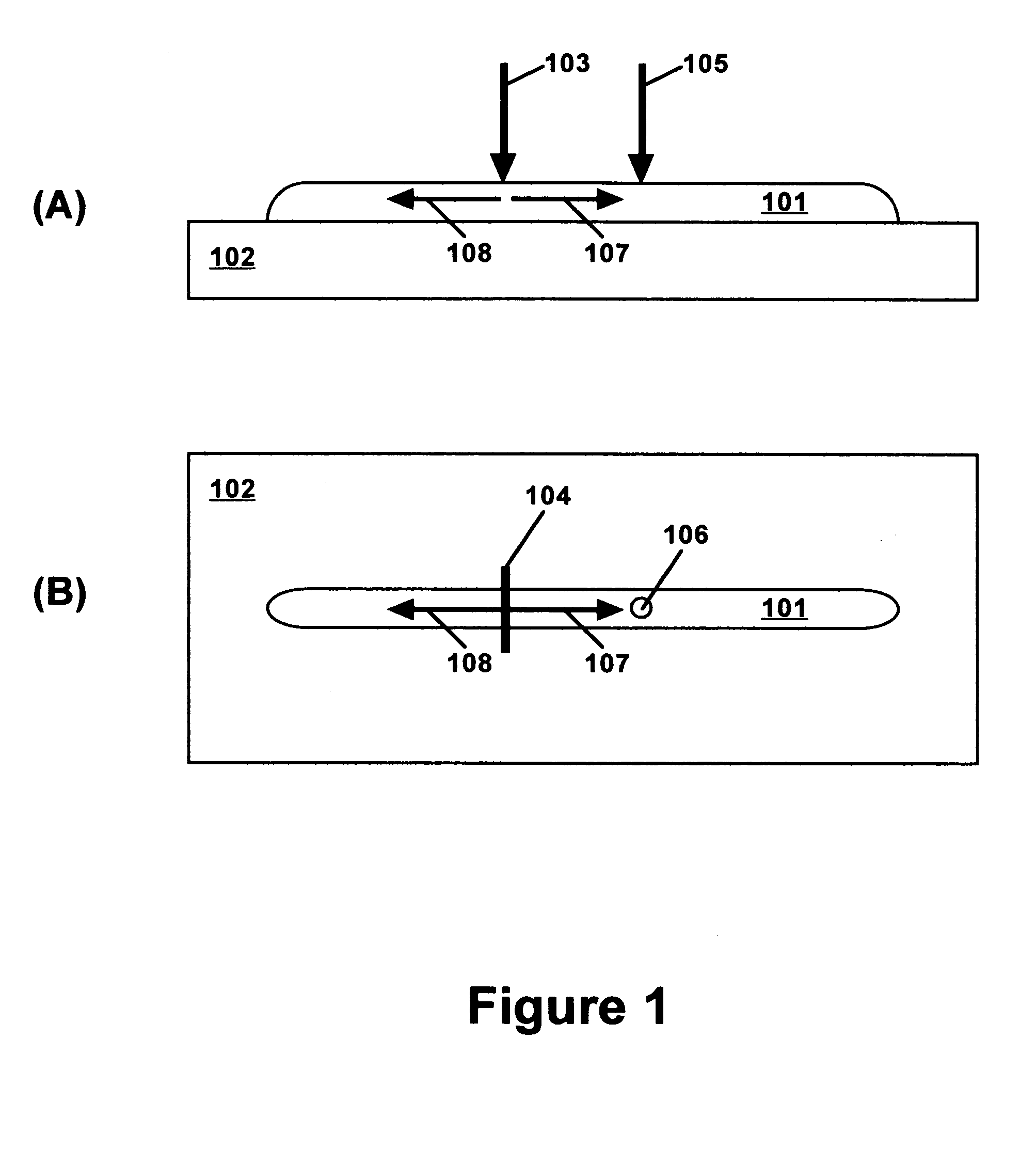

Image

Examples

example 1

[0049]FIG. 4 shows acoustic waveforms illustrating detection according to the invention of a simulated defect (blind hole 1.5 mm diameter and 0.4 mm deep in the back surface) in a machined stainless steel plate (6.4 mm thick). When the detection spot did not overlap the simulated defect, the acoustic waveform exhibited a relatively narrow peak (labeled “no overlap” in FIG. 4) corresponding to arrival of the direct-arriving Rayleigh wave, which was generated at a time of 1 μs in the plot of FIG. 4. When the detection spot did overlap the simulated defect, this peak (labeled “defect overlap” in FIG. 4) was broadened by the signal corresponding to arrival of the scattered acoustic wave at a later time.

example 2

[0050] A B-scan was generated for a machined stainless steel plate (6.4 mm thick) with a simulated defect (blind hole 1.5 mm diameter and 0.4 mm deep in the back surface). The defect was detected at the expected location in the B-scan as a time-delayed bulge in the vertical line corresponding to the direct-arriving Rayleigh wave.

example 3

[0051] A B-scan was generated for a machined titanium alloy 4-6 plate (6.7 mm thick) with a simulated defect (blind hole 1.0 mm diameter and 0.4 mm deep in the back surface). The defect was detected at the expected location in the B-scan as a time-delayed bulge in the vertical line corresponding to the direct-arriving Rayleigh wave. There is less grain scattering in titanium than in steel, so that more ultrasonic features were visible in the titanium plate. In addition to the bulge associated with direct scattering from the simulated defect, the B-scan exhibited two prominent diagonal lines that are associated with surface waves reflected from this defect. These diagonal lines, whose slopes depend on the surface wave velocity, may also be useful for defect detection and localization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com