SLM Lithography: Printing to below K1=.30 without previous OPC processing

a technology of lithography and opc processing, applied in the field of slm lit, can solve the problems of limiting the resolution and fidelity that can be achieved, the optics used in lithographic processes are extremely well designed, and the only limitation is the underlying physics, so as to achieve the effect of size errors for everything close to the resolution limi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following detailed description is made with reference to the figures. Preferred embodiments are described to illustrate the present invention, not to limit its scope, which is defined by the claims. Those of ordinary skill in the art will recognize a variety of equivalent variations on the description that follows.

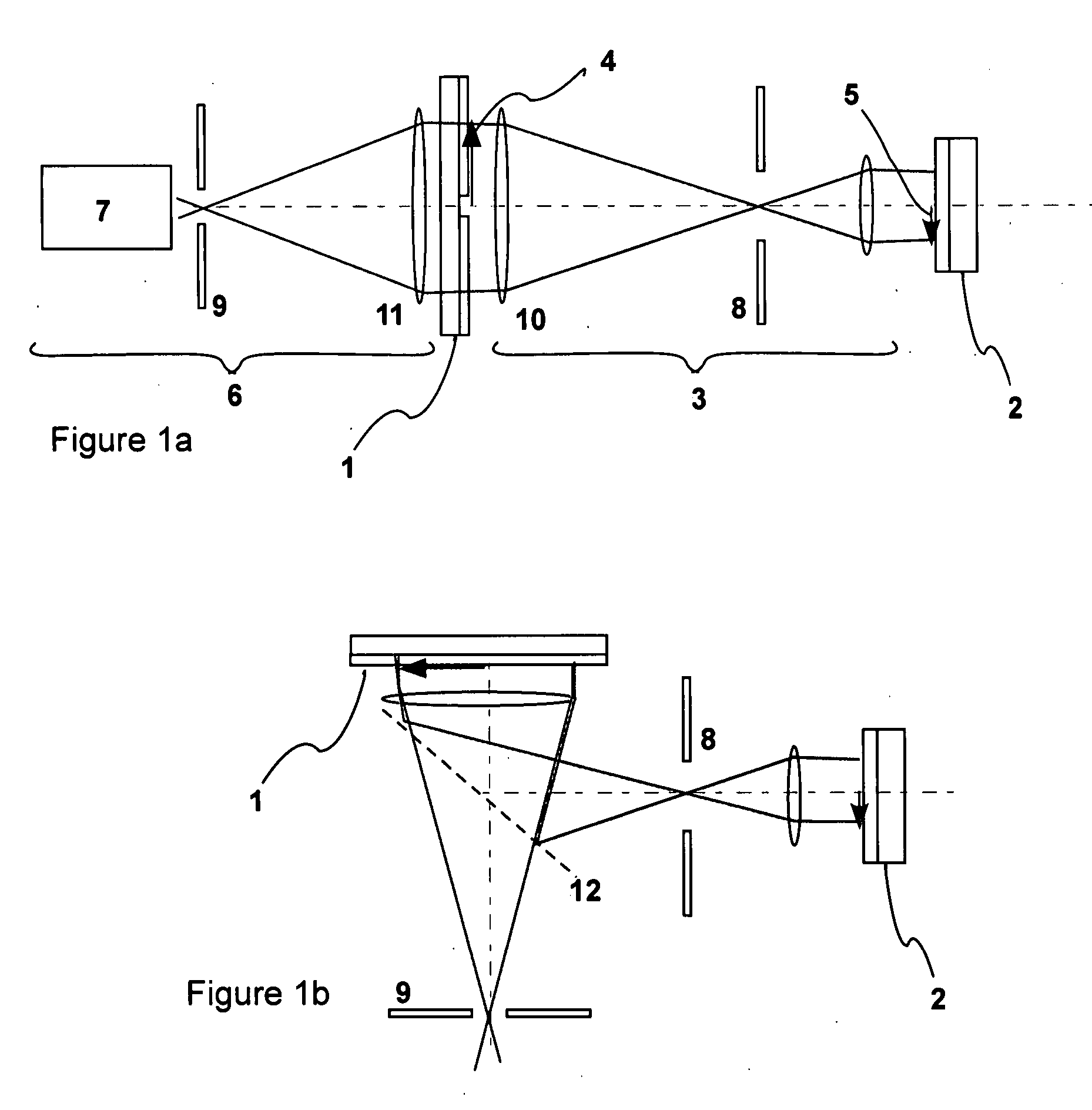

Generic Projection System / Platform

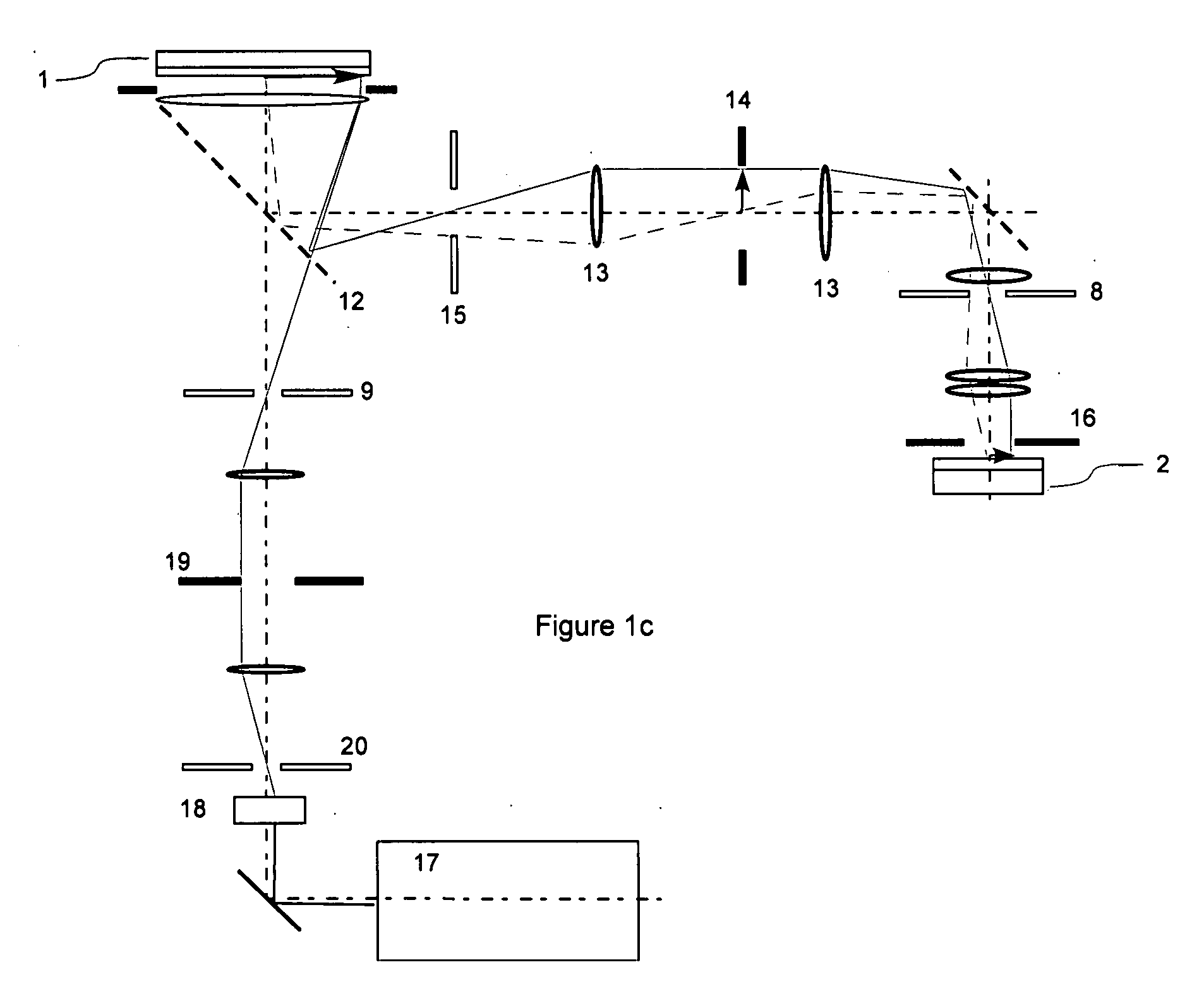

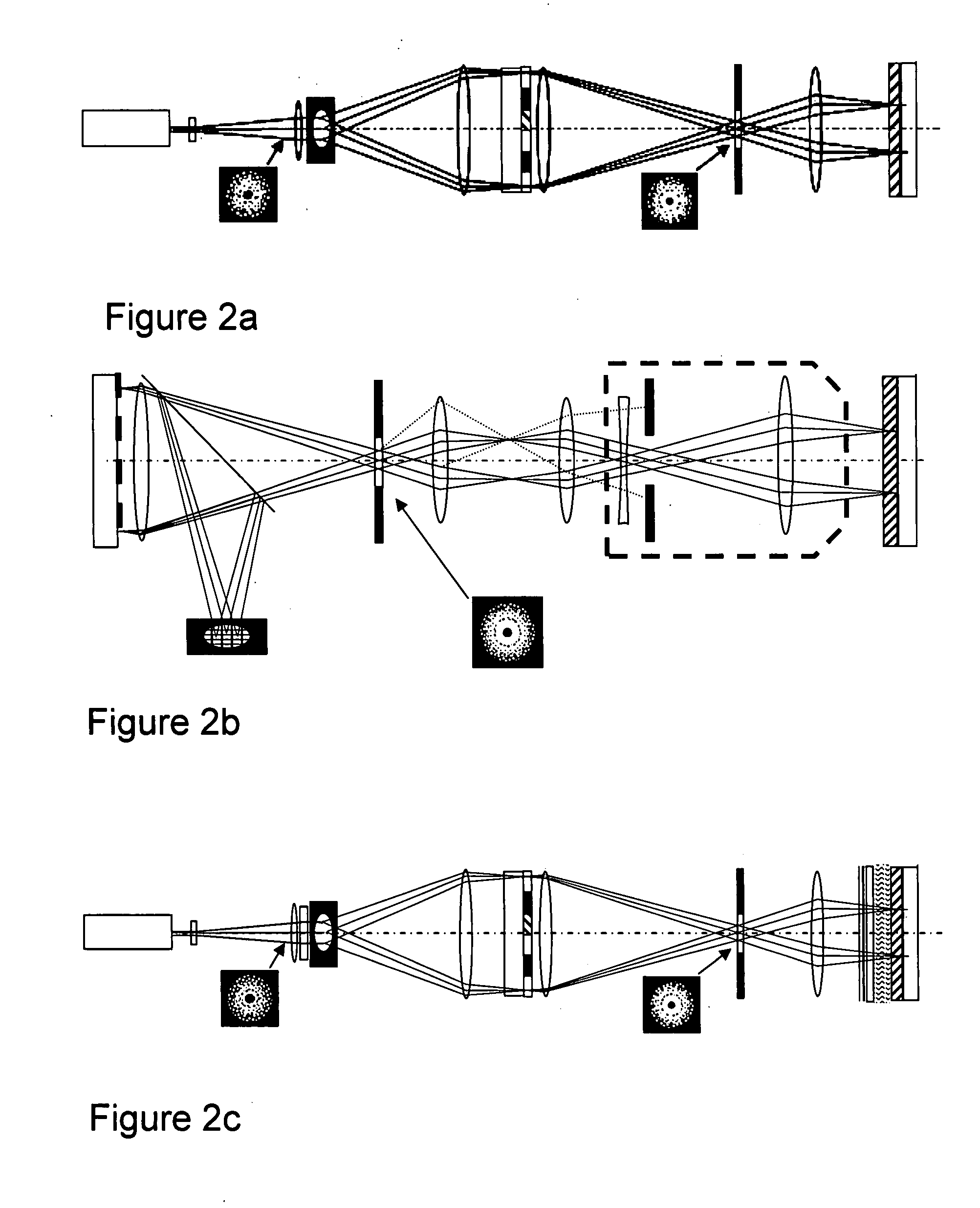

[0055] A generic projection system has been defined in FIG. 1a. It has an object 1, which can be a mask or one or several SLMs, and a workpiece 2, e.g., a mask blank, a wafer or a display device. Between them is a projection system 3 creating an image 5 of the image 4 on the object. The object is illuminated by an illuminator 6. The projection system consists of one or several lenses (shown) or curved mirrors. The NA of the projection system is determined by the size of the pupil 8. The illuminator 6 consists of an essentially non-coherent light source 7 illuminating the illumination aperture 9. Field lenses 10 and 11 are sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com