Shutdown seal for reactor coolant pump

a technology for coolant pumps and shut-down seals, which is applied in the direction of pump heads, positive displacement liquid engines, liquid fuel engines, etc., can solve the problems of the rotating components of the pump to begin to coast down to a stationary condition, and achieve the effect of minimal effect and little or no impact on the seals already in the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

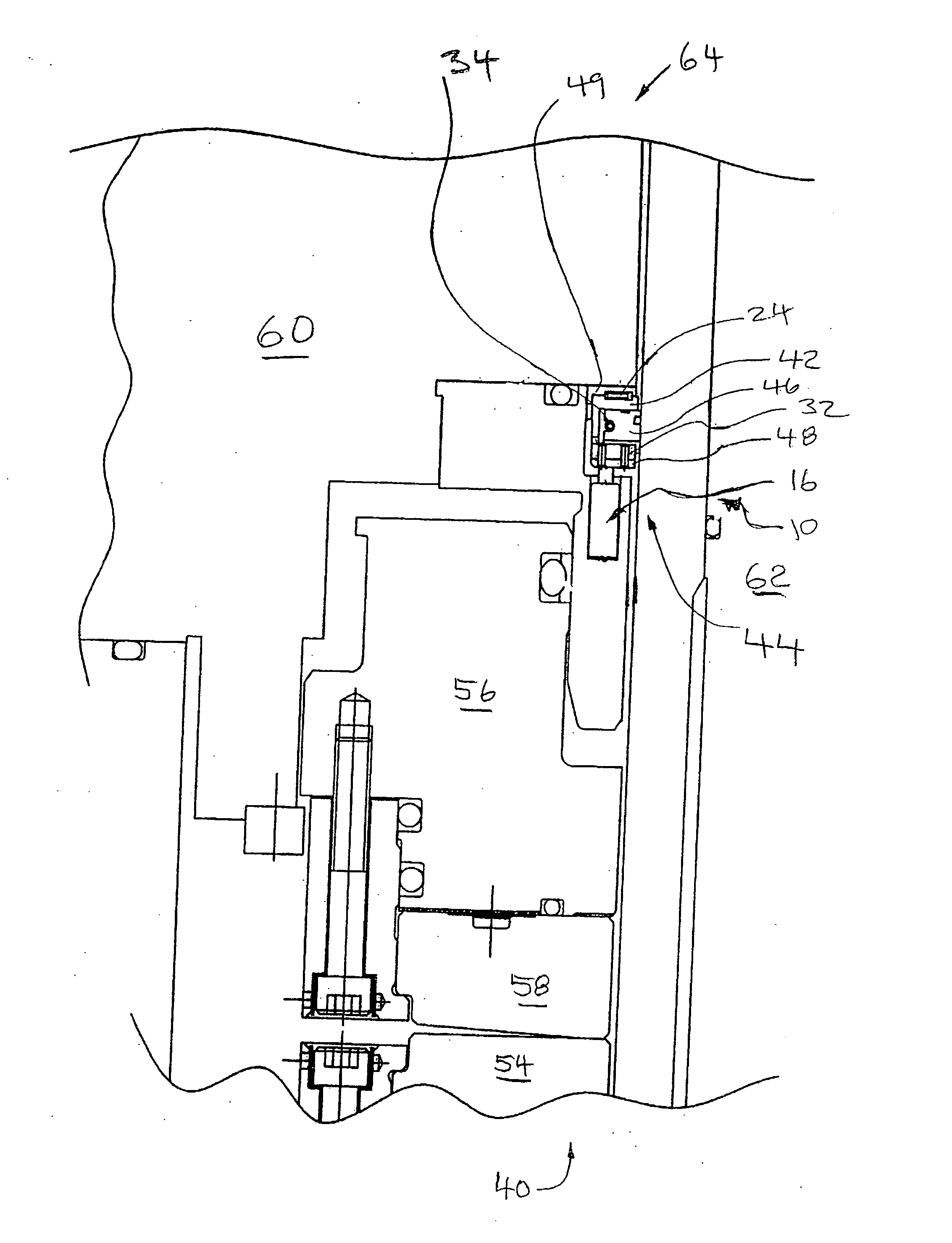

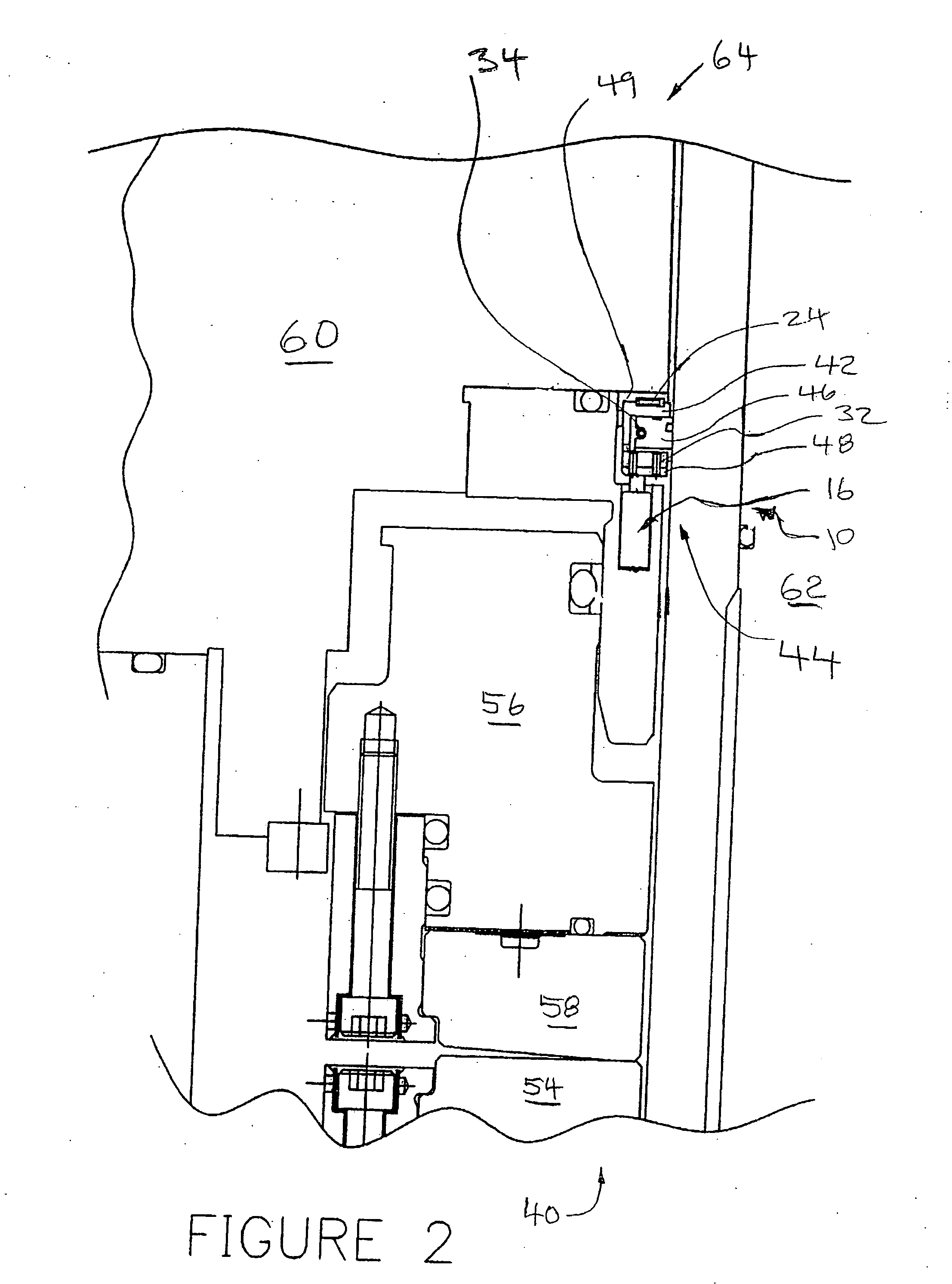

[0050] Referring to the drawings in general and to FIG. 1 in particular, the broken longitudinal section of a portion of a exemplary prior art reactor coolant pump reveals the primary seal assembly of the pump, with the primary seal assembly being designated generally 40 and including a runner faceplate 54 and a ring faceplate 58, with exceedingly small space identified as 122 between these faceplates defining the primary seal. A area filled with high pressure coolant water within the pump during normal operation is denoted generally 66. During normal pump operation coolant water pressure in area 66 may be as high as two thousand two hundred-fifty pounds per square inch (2,250 psi).

[0051] The pump includes a motor rotatably driving a pump shaft 62. The shaft 62 shown in FIG. 1; the motor is not illustrated in FIG. 1 but is normally located at what is, relative to FIG. 1, the lower end of pump shaft 62. Further affixed to pump shaft 62, and driven by pump shaft 62 as pump shaft 62 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com