Use of chlorine to fabricate trench dielectric in integrated circuits

a dielectric and integrated circuit technology, applied in the field of integrated circuits, can solve problems such as overerase and/or other problems, and achieve the effects of preventing undue consumption of active area, reducing the oxidation time, and enhancing the corner rounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments described in this section illustrate but do not limit the invention. The invention is not limited to particular fabrication techniques or numerical values and ranges. The invention is defined by the appended claims.

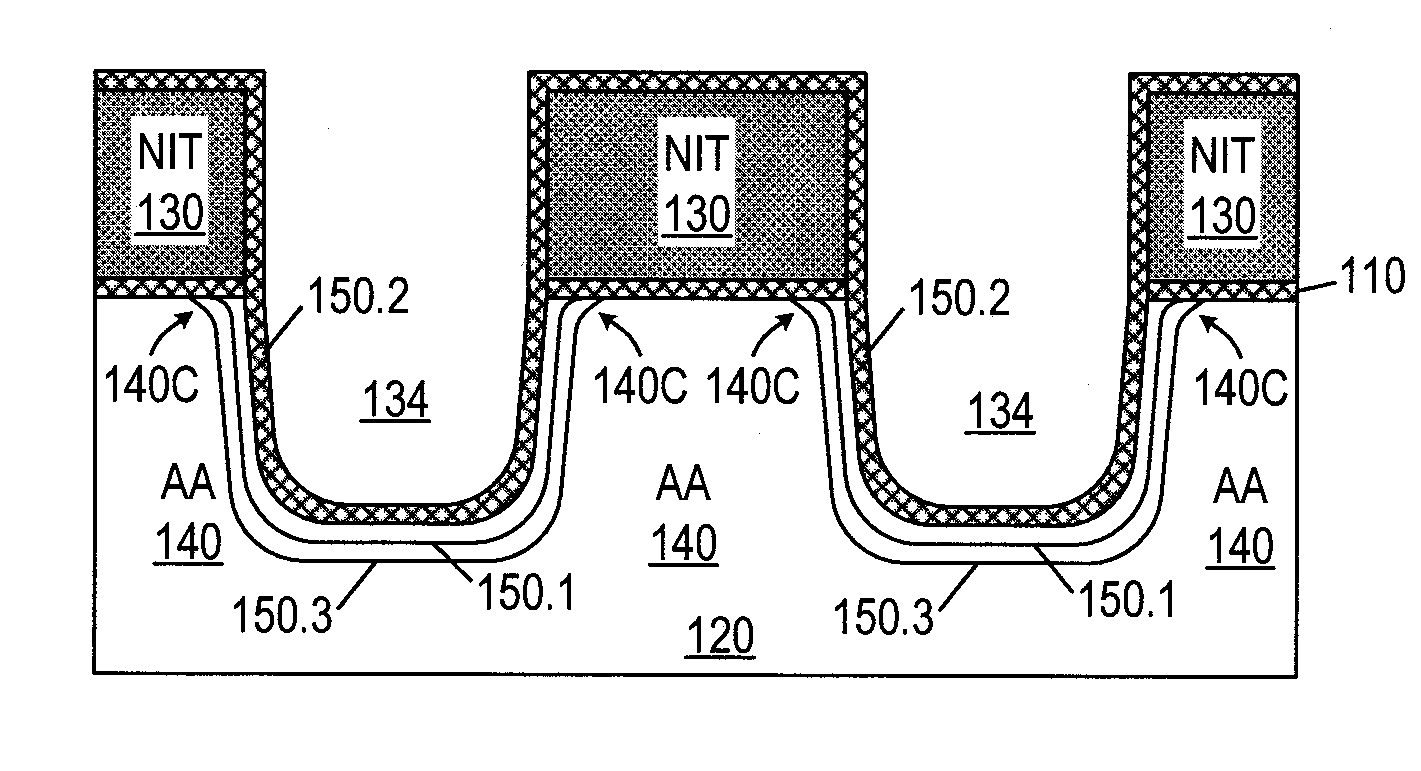

[0018]FIG. 9 illustrates initial STI fabrication stages in one embodiment of the present invention. Silicon dioxide layer 110 comprising chlorine atoms is formed on silicon wafer 120. In some embodiments, the chlorine concentration is more than three atomic percent, or at least 5 atomic percent. A range from 5 to 15 atomic percent is believed to be suitable, and other concentrations are possible.

[0019] In one embodiment, oxide 110 is formed by thermal oxidation at 800˜1000° C. The oxygen flow is 10±5 l / m in (liters per minute). The chlorine is provided by hydrogen chloride (HCl) flown at 1 l / min. Other possible chlorine sources include the chlorine gas (Cl), TCA (trichloroethane, C2H3Cl3), TCE (trichloroethylene, C2HCl2), dichloroethylene (C2H2Cl2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com