Thin prestressed concrete panel and apparatus for making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

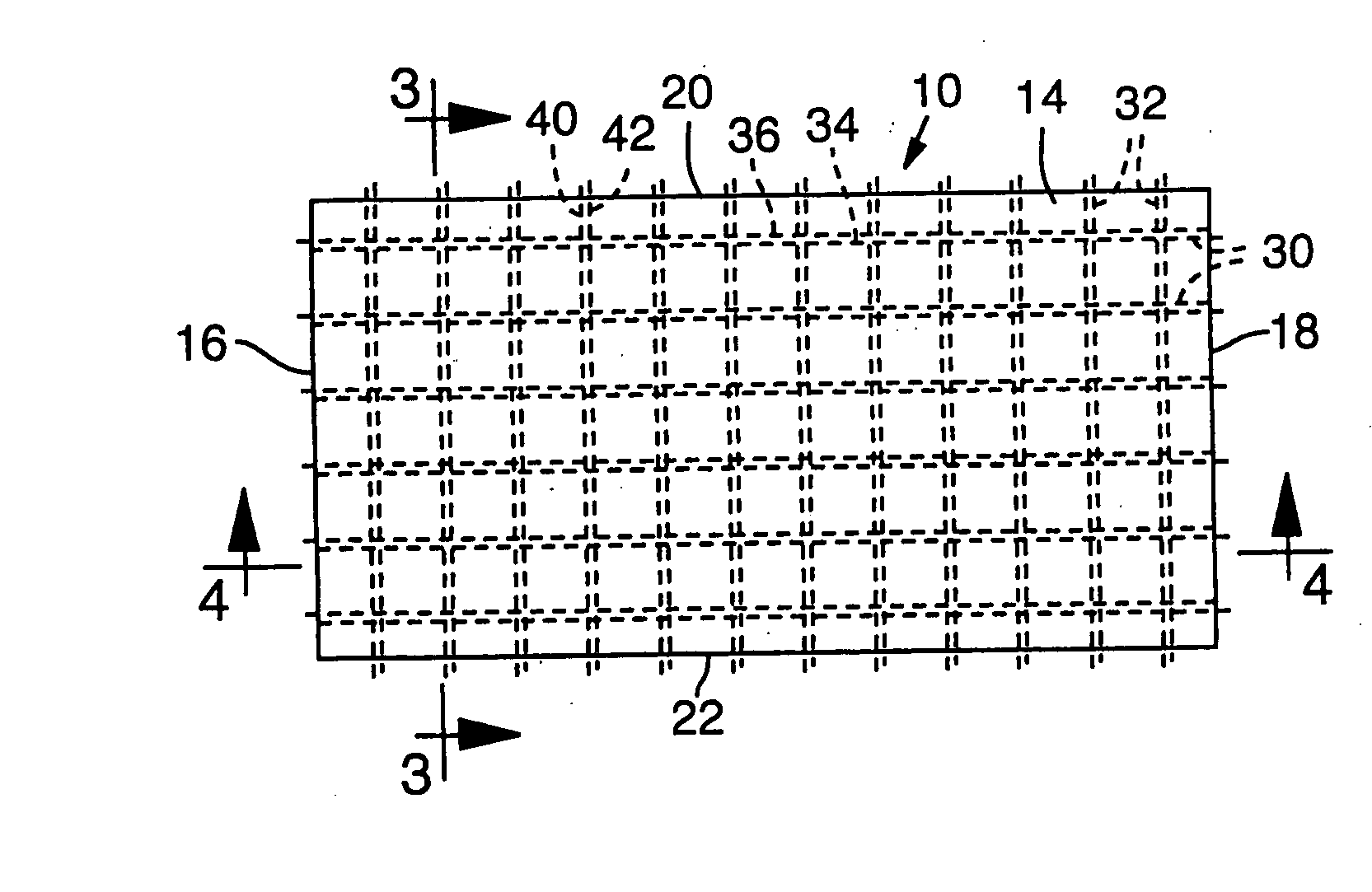

[0027] Referring first to FIGS. 1-4, there is therein illustrated a preferred embodiment of the invention comprising a thin prestressed, reinforced concrete panel 10, which may be, for example, approximately 50 inches in length, 25 inches in width and have a ⅝ inch thickness. This size is only illustrative since the panel may be made in a wide variety of sizes. A thin panel as used herein refers to a panel with a maximum thickness of approximately 1.5 inches.

[0028] The illustrated panel 10 is formed with an exposed face 12 and an opposite back face 14 each of which faces are flat and parallel to one another. Alternatively, the exposed face 12 may be textured rather than flat to achieve a desired architectural appearance on the panel. Panel 10 is shown as formed with a pair of opposite end faces, or edges, 16, 18, and a pair of opposite side faces, or edges, 20, 22. In the illustrated embodiment the side and end faces are beveled such that the back face 14 is of larger dimensions in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com