Faraday Rotator, Optical Isolator, Polarizer, and Diamond-Like Carbon Thin Film

a technology of diamond-like carbon thin film and polarizer, which is applied in the field of faraday rotators, optical isolators, polarizers and diamond-like carbon thin films, can solve the problems of large overall size, high cost of faraday rotators, polarizers (analyzers), and noise produced by beams returning to light sources, so as to improve the performance of polarizers and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

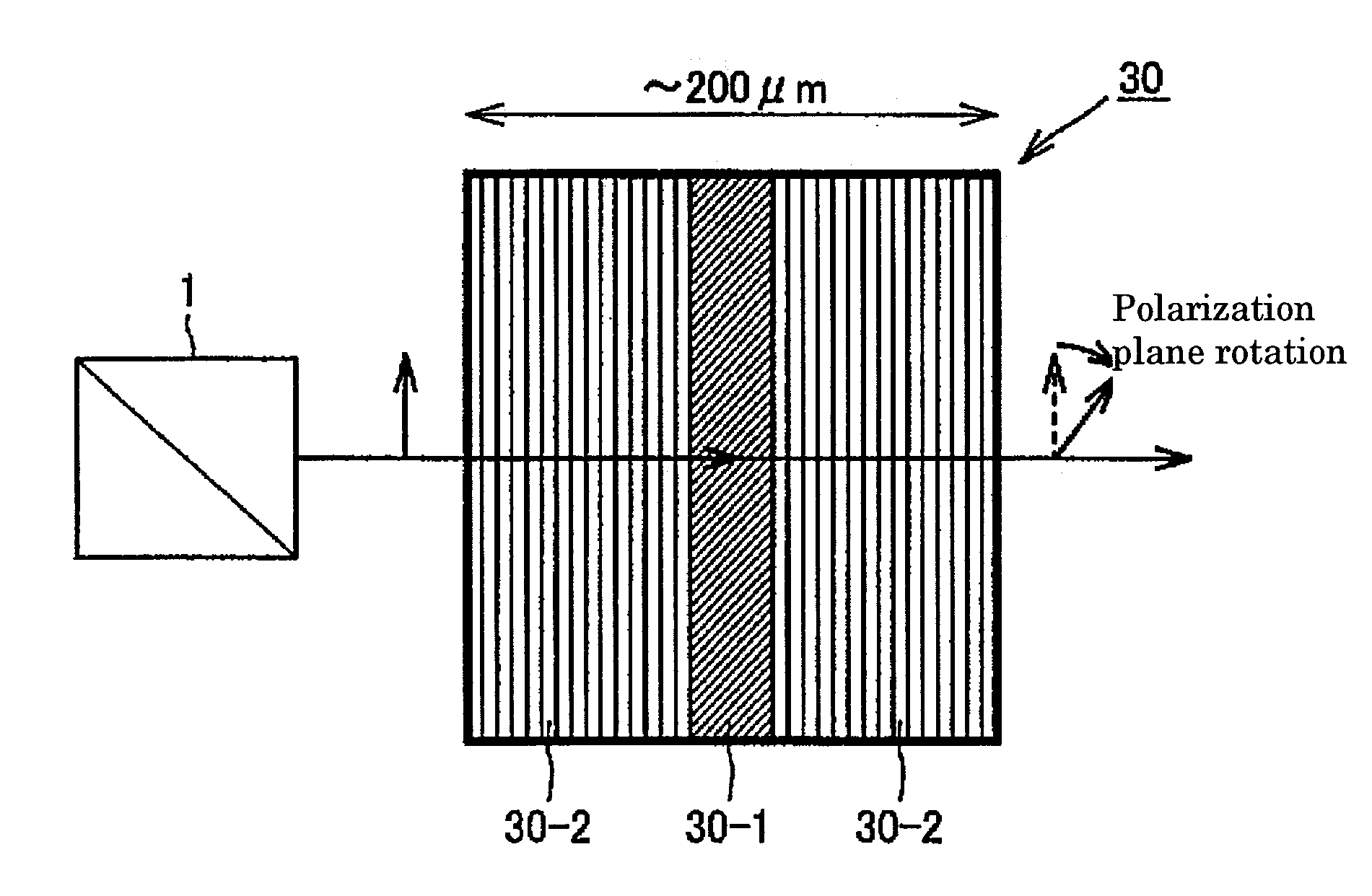

[0051]FIG. 1 is a view schematically illustrating a Faraday rotator of Embodiment 1 according to the invention.

[0052] This Faraday rotator 30 is furnished with, as shown in FIG. 1, a magneto-optical part 30-1 for rotating the polarization plane of incident light traveling in the direction of its magnetic field, and dielectric multi-layer films 30-2 for localizing within the magneto-optical part 30-1 incident light of at least one wavelength.

[0053] The magneto-optical part 30-1 is constituted from a gadolinium iron garnet (GIG hereinafter) thin film, and the dielectric multi-layer films 30-2 are composed by laminating in alternation silicon dioxide as a low refractive-index layer, and titanium dioxide as a high refractive index layer.

[0054] As shown in FIG. 1, the Faraday rotator 30 is constituted by arranging the dielectric multi-layer films30-2 on either side of the magneto-optical part 30-1 to create a resonant structure. The resonant structure of the dielectric multi-layer fil...

embodiment 2

[0080]FIGS. 8 and 9 are views schematically illustrating optical isolators of Embodiment 2 according to the invention.

[0081] Optical isolator 60a in FIG. 8 is constructed by arranging a polarizer 20 and an analyzer 40 on either side of the Faraday rotator depicted in Embodiment 1, and further arranging magnetic parts 5 along the top and bottom.

[0082] As explained in setting out Embodiment 1, the Faraday rotator 30 functions to selectively rotate only the polarization plane of incident light of a given wavelength(s). This enables optical isolator 60a incorporating the Faraday rotator 30 to selectively block only the return beams from the incident light of the given wavelength(s).

[0083] The polarizer 20 and the analyzer 40 can be constituted by irradiating a diamond-like carbon (DLC hereinafter) thin film along a bias with either a particle beam or an energy beam. (Details of a polarizer (analyzer) constituted using the DLC thin film will be described in Embodiment 3.)

[0084] Accor...

embodiment 3

[0088]FIG. 10 is a view schematically illustrating a manufacturing process of a polarizer according to Embodiment 3 of the invention.

[0089] The polarizer is characterized in being formed by irradiating a DLC thin film 11 along a bias with either a particle beam or an energy beam. Although ion beams, electron beams, proton beams, α-rays and neutron beams are conceivable particle beams, and light rays, x-rays and γ-rays are conceivable energy beams, taking the example herein of irradiating with ion beams, a method of lending a refractive index distribution to the DLC thin film will be explained with reference to FIG. 10.

[0090] As indicated in FIG. 10, at first a mask 12 that is a transcription of a refractive-index distribution pattern is adhered atop the DLC thin film. From above the mask 12, oblique irradiation is performed with a beam of helium or argon ions, for example. The refractive index of the portions as at 11-1 receiving ion-beam irradiation through the transmitting areas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| in-plane thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com