Phosphor, light emitting device using phosphor, and display and lighting system using light emitting device

a light emitting device and light emitting device technology, applied in the direction of luminescent compositions, discharge tubes/lamp details, discharge tubes luminescent compositions, etc., can solve the problems of low color rendering property of light emitting devices, phosphor is not necessarily easy to produce, and phosphor tends to be deteriorated in brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0055] 0.0297 mol of CaCO3 as a M1-source compound, 0.01 mol of Sc2O3 as a M2-source compound, 0.03 mol of SiO2 as a M3-source compound and 0.0003 mol of Ce(OCOCH3)3 as a luminescent center ion element-source compound were pulverized and mixed together with pure water in a wet ball mill including an alumina container and beads, dried and then passed through a nylon mesh. The resultant pulverized mixture was heat-calcined in an alumina crucible under atmospheric air at 1,400° C. for 2 hours, and successively subjected to water-washing, drying and classification, thereby producing a phosphor.

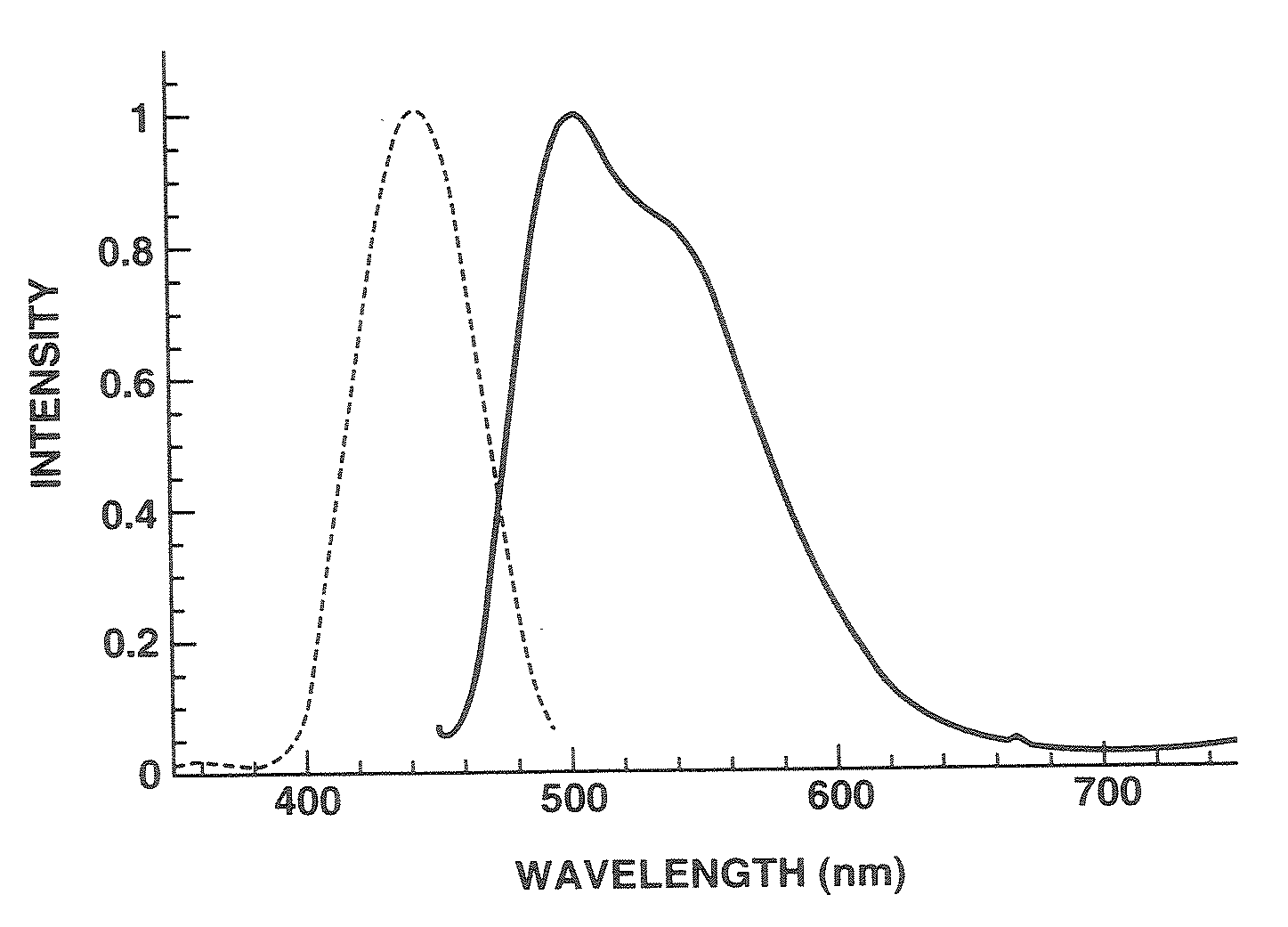

[0056] As a result of analyzing the thus obtained phosphor by powder X-ray diffraction method, it was confirmed that the phosphor contained a host material composed of a compound of a garnet crystal structure having a composition as shown in Table 1, and trivalent Ce as a luminescent center ion incorporated in the host material. Further, the phosphor was subjected to measurements of emission spec...

example 2

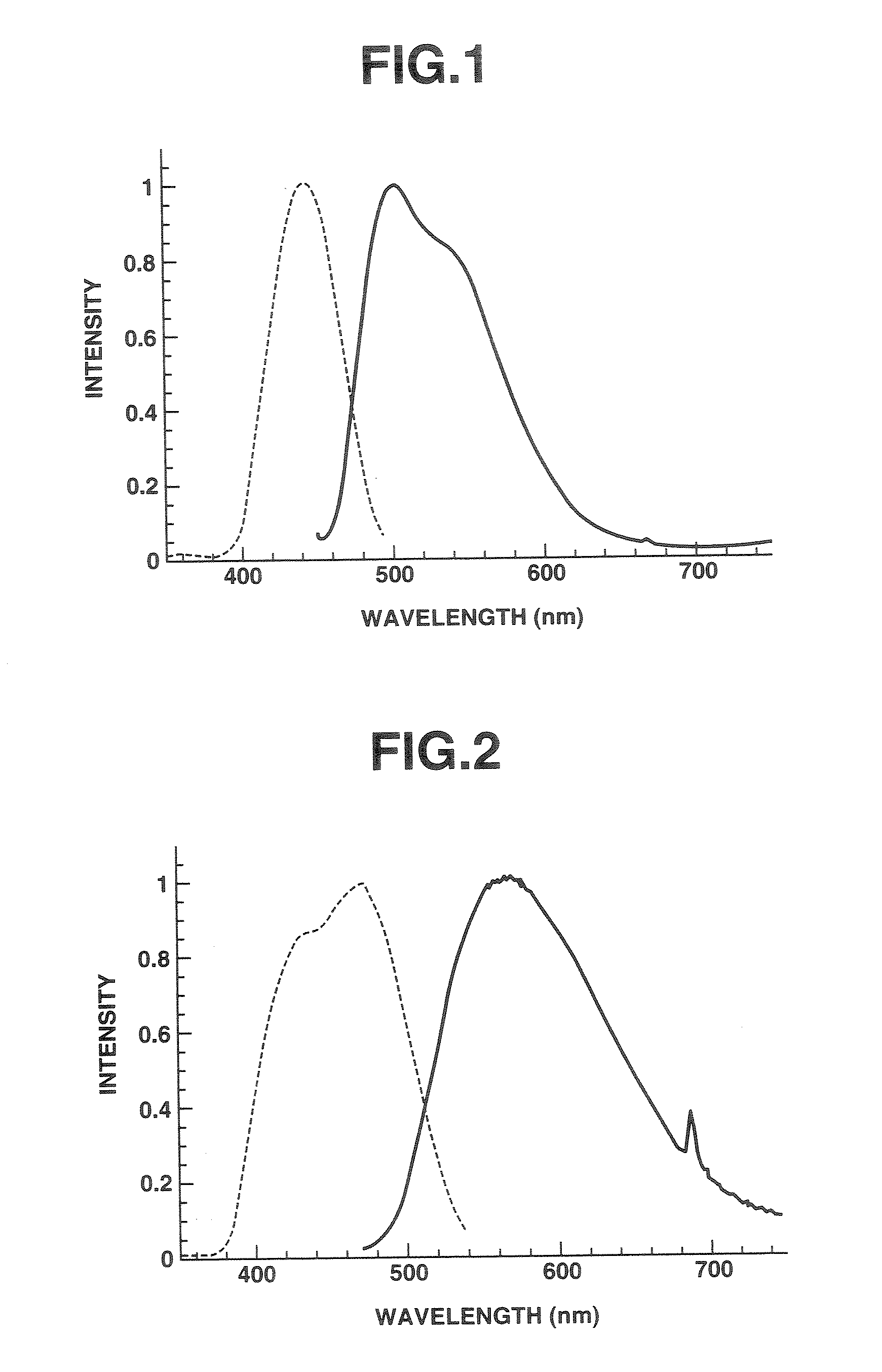

[0057] The same procedure as defined in Example 1 was conducted except that 0.0147 mol of CaCO3 and 0.015 mol (as Mg) of Mg(OH)2.3MgCO3.3H2O were used as a M1-source compound, and 0.0075 mol of Sc2O3 and 0.0025 mol of Y2O3 were used as a M2-source compound, thereby producing a phosphor. As a result of analyzing the thus obtained phosphor by powder X-ray diffraction method, it was confirmed that the phosphor contained a host material composed of a compound of a garnet crystal structure having a composition as shown in Table 1, and trivalent Ce incorporated as a luminescent center ion in the host material. Further, the phosphor was subjected to measurements of emission spectrum and excitation spectrum thereof. The results are shown in FIG. 2. From the thus measured emission spectrum, the color coordinates x and y were calculated by the same method as in Example 1. As a result, it was confirmed that x was 0.43 (x=0.43), y was 0.53 (y=0.53), and a sum of x and y was 0.96 ((x+y)=0.96). F...

example 3

[0058] The same procedure as defined in Example 1 was conducted except that the heat-treating temperature was changed to 1,200° C., thereby producing a phosphor. As a result of analyzing the thus obtained phosphor by powder X-ray diffraction method, it was confirmed that the phosphor contained a host material composed of a compound of a garnet crystal structure having a composition as shown in Table 1, and trivalent Ce incorporated as a luminescent center ion in the host material. From the measured emission spectrum of the phosphor, the color coordinates x and y were calculated by the same method as in Example 1. As a result, it was confirmed that x was 0.28 (x=0.28), y was 0.54 (y=0.54), and a sum of x and y was 0.82 ((x+y)=0.82). Further, the phosphor was irradiated with a blue light by the same method as in Example 1, while controlling an irradiation intensity thereof. As a result, the phosphor absorbed the blue light and emitted a yellowish green color light, and further the emi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index R5 | aaaaa | aaaaa |

| color rendering index R5 | aaaaa | aaaaa |

| color rendering index Ra | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com