Vertically-aligned (VA) liquid crystal display device

a vertical alignment and liquid crystal display technology, applied in the direction of identification means, instruments, polarising elements, etc., to achieve the effect of improving the viewing angle characteristic, same contrast and operation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0315]FIGS. 18A and 18B are diagrams showing the position of a liquid-crystal injection port of the liquid crystal panel 100 of the first embodiment through which a liquid crystal is injected. As described later, in the process of assembling components to produce a liquid-crystal panel, after the CF substrate and TFT substrate are bonded to each other, a liquid crystal is injected. As far as a VA type TFT LCD is concerned, it takes much time to inject a liquid crystal compared with the TN LCD in general. Since protrusions are formed, it takes much more time to inject a liquid crystal. For shortening the time required for injecting the liquid crystal, as shown in FIG. 18A, a liquid-crystal injection port 102 should preferably be formed on a side vertical to the direction in which the protrusions are arrayed parallel to one another on a cyclic basis. Reference numeral 101 denotes a sealing line.

[0316] During injection of a liquid crystal, when the interior of the panel is deaerated th...

second embodiment

[0318] After an intermediate voltage is applied to the panel of the second embodiment, the interior of the panel is observed using a microscope. The observation has revealed that very stable alignment is attained.

[0319] Furthermore, in the panel of the first embodiment, a response speed has quite improved. FIGS. 20A to 21 are diagrams indicating a changing value of the response speed permitted by the panel of the first embodiment in relation to changes in parameters that are an applied voltage and a spacing (gap) between upper and lower protrusions. FIG. 20A indicates an on speed (for transition from 0 to 5 V), FIG. 20B indicates an off speed (for transition from 5 to 0 V), and FIG. 21 indicates a switching speed that is a sum of the on speed and off speed. As shown in FIGS. 20A to 21, a fall time off is hardly dependent on the spacing but a rise time on varies greatly. The smaller the spacing is, the higher the response speed becomes. Incidentally, the thickness of cells is 3.5 mic...

fourth embodiment

[0334] Moreover, in a modification of the fourth embodiment, as shown in FIG. 37B, tapered juts 46 are formed on each protrusion 20. Even in this case, the length of each tapered portion is about 50 micrometers or less than it. For creating a pattern of this kind of protrusions, the pattern is drawn using a positive resist, and the protrusions 20 are created by performing slight etching. A positive resist whose thickness is about a half of the height of the protrusions is applied, and the tapered juts 46 on the protrusions 2 are left intact by performing slight etching. With the juts, the alignment of liquid crystalline molecules near the apices of the juts can be controlled.

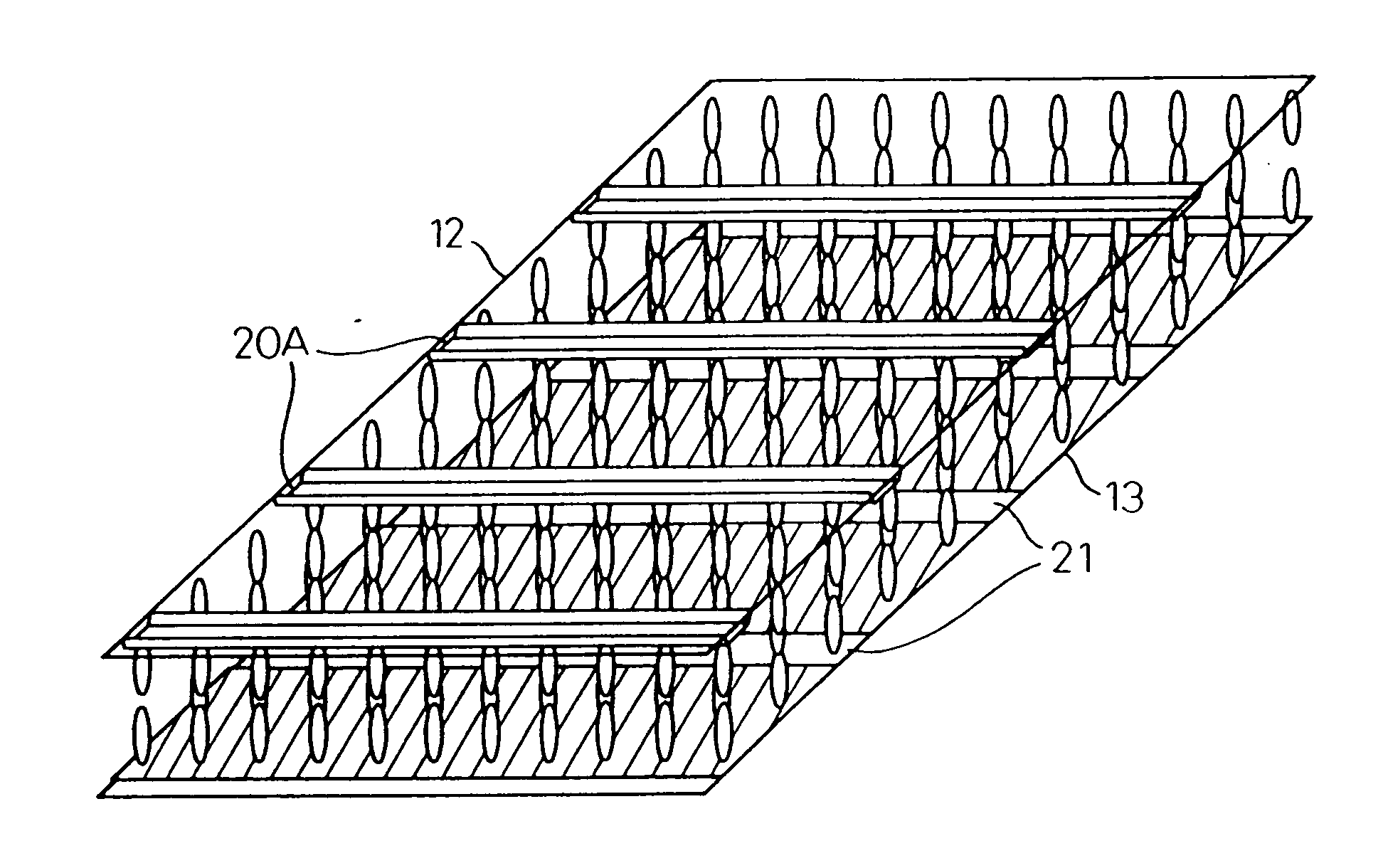

[0335]FIGS. 38A and 38B are diagrams showing the structure of a panel in the fifth embodiment. FIG. 38A is a diagram illustratively showing a state in which the panel is seen obliquely, and FIG. 38B is a side view. The fifth embodiment is an example in which the structure of a panel corresponds to the structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

| polar angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com