Brightness enhancement film with improved view angle

a technology of brightness enhancement and view angle, applied in the direction of planar/plate-like light guides, lighting and heating apparatuses, instruments, etc., can solve the problems of side-lobes and unsatisfactory security, and achieve the effect of small reduction of peak brightness and increased useful illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

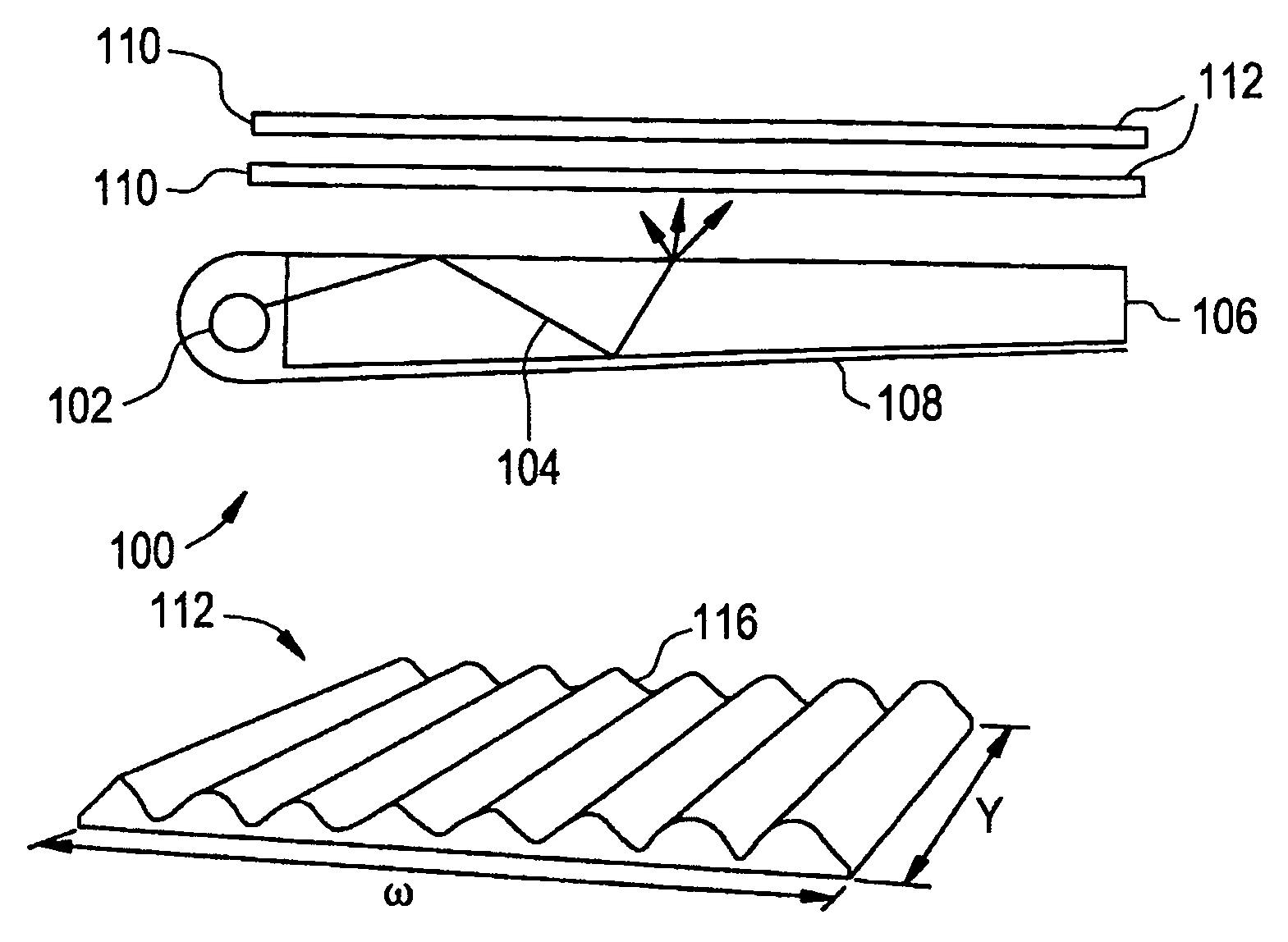

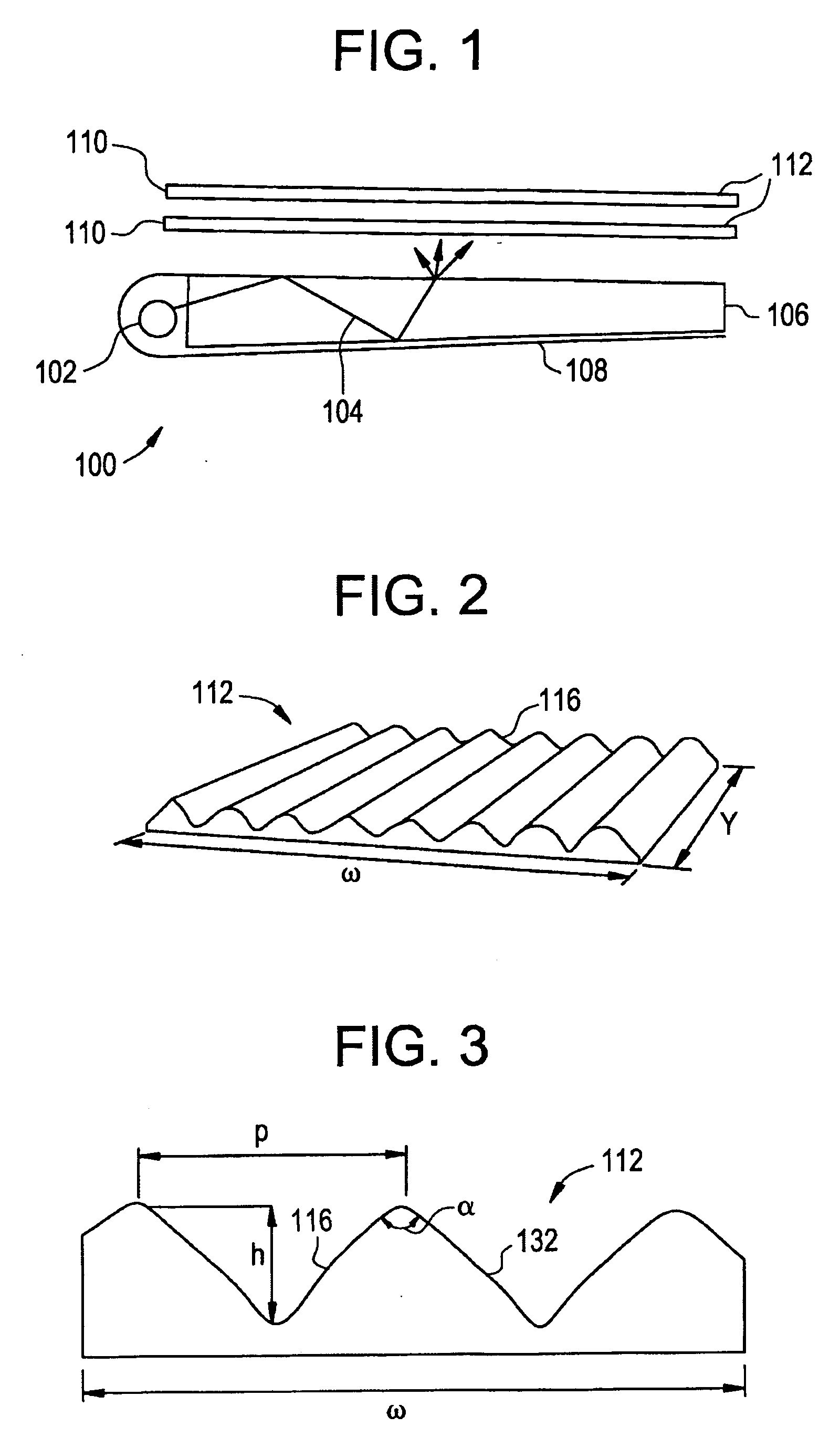

[0022] The optical substrates 110 may be positioned, one above the other, in a crossed configuration wherein the prismatic structures 116 are positioned at an angle with respect to one another (e.g., 90 degrees) as seen in FIG. 7. The prisms 116 have a prescribed peak angle, a, a height, h, a length, 1, and a pitch, p and one or both of the prismatic surfaces 112 may be randomized in their peak angle, a, height, h, length, 1, and pitch, p. Yet further, one or both sides of the substrates 110 may have the prisms 116. In FIGS. 2, 3 and 4, in the invention, the sidewall or facets 132 of the prisms 116 which comprise the surface 112 are curved. The curvature can be described as a segment of a parabola, or more generally as a polynomial surface given by the sag equation: z=cr21+1-(1+k)c2r2+dr2+er4+fr6+Higher order terms in r(1)

where z is the perpendicular deviation (or “sag”) in microns of the sidewall or facet 132 of the prisms 116 from a straight reference line 128, origina...

second embodiment

[0025] In a second embodiment, a relatively high index of refraction for the optical substrate 110 in combination with a modified prism geometry yields an enhanced brightness. In particular, FIG. 8 displays a map of the central luminance in per cent of crossed optical substrates as a function of the prism peak angle and the refractive index of the substrate, wherein a refractive index of 1.6 and a peak angle of 90 degrees is taken to be 100 per cent. By increasing the peak angle to 100 degrees and increasing the refractive index of the optical substrate generally to greater than about 1.65 and in particular to between approximately 1.7 and 1.8, the luminance is at least 102 per cent.

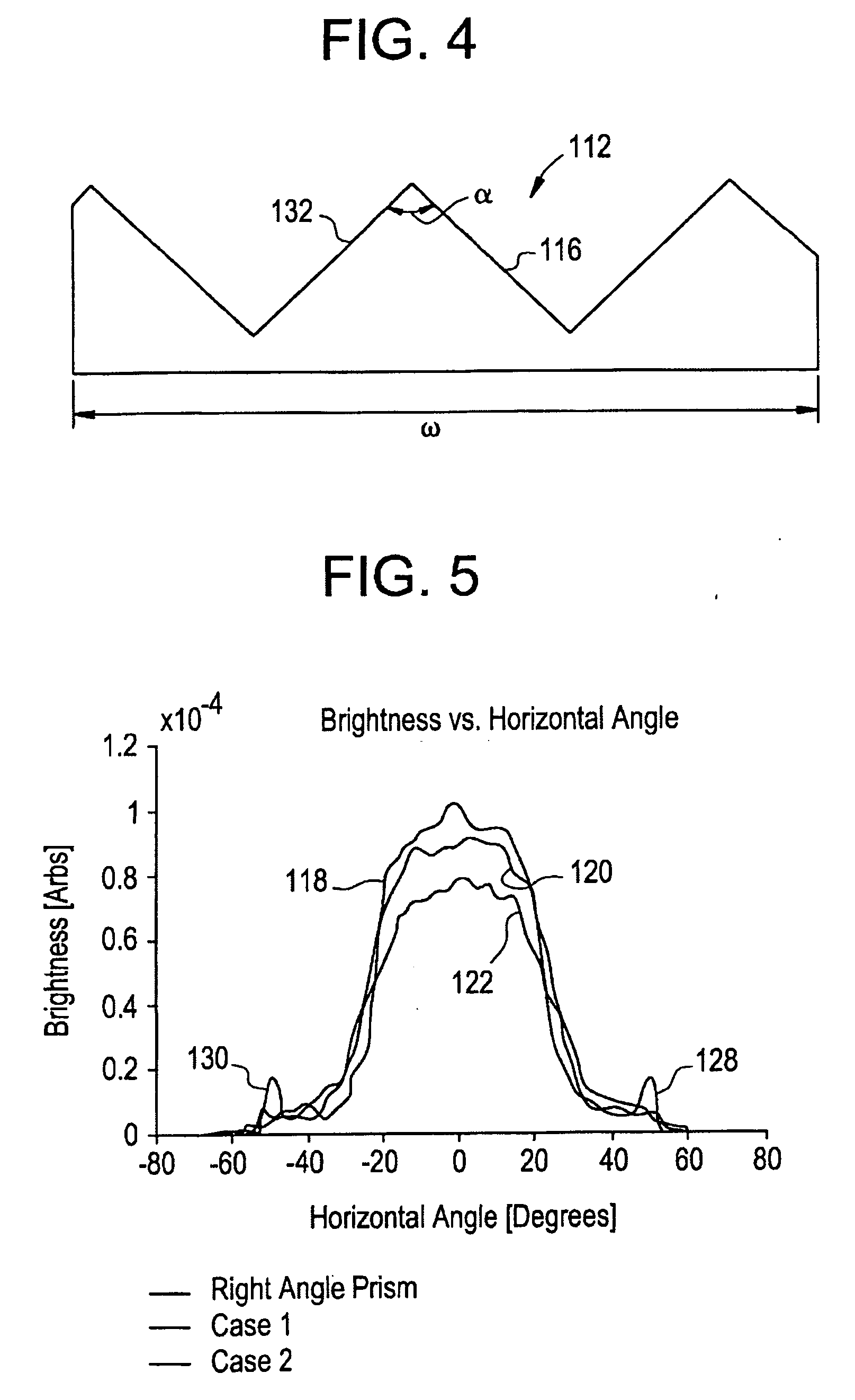

[0026]FIG. 9 shows a graphical depiction of the far field horizontal luminance of crossed optical substrates as a function of horizontal viewing angle. In FIG. 9, a prior art luminance profile, based upon a refractive index of 1.65 and a peak prism angle of 90 degrees is shown at 150. As can be seen in F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com