Pest control system

a control system and pest technology, applied in the field of pest control systems, can solve the problems of unfavorable environmental protection, unfavorable human health, and certain risks to the environment, and achieve the effects of preserving structural integrity of the building or enclosure, and reducing the impact of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

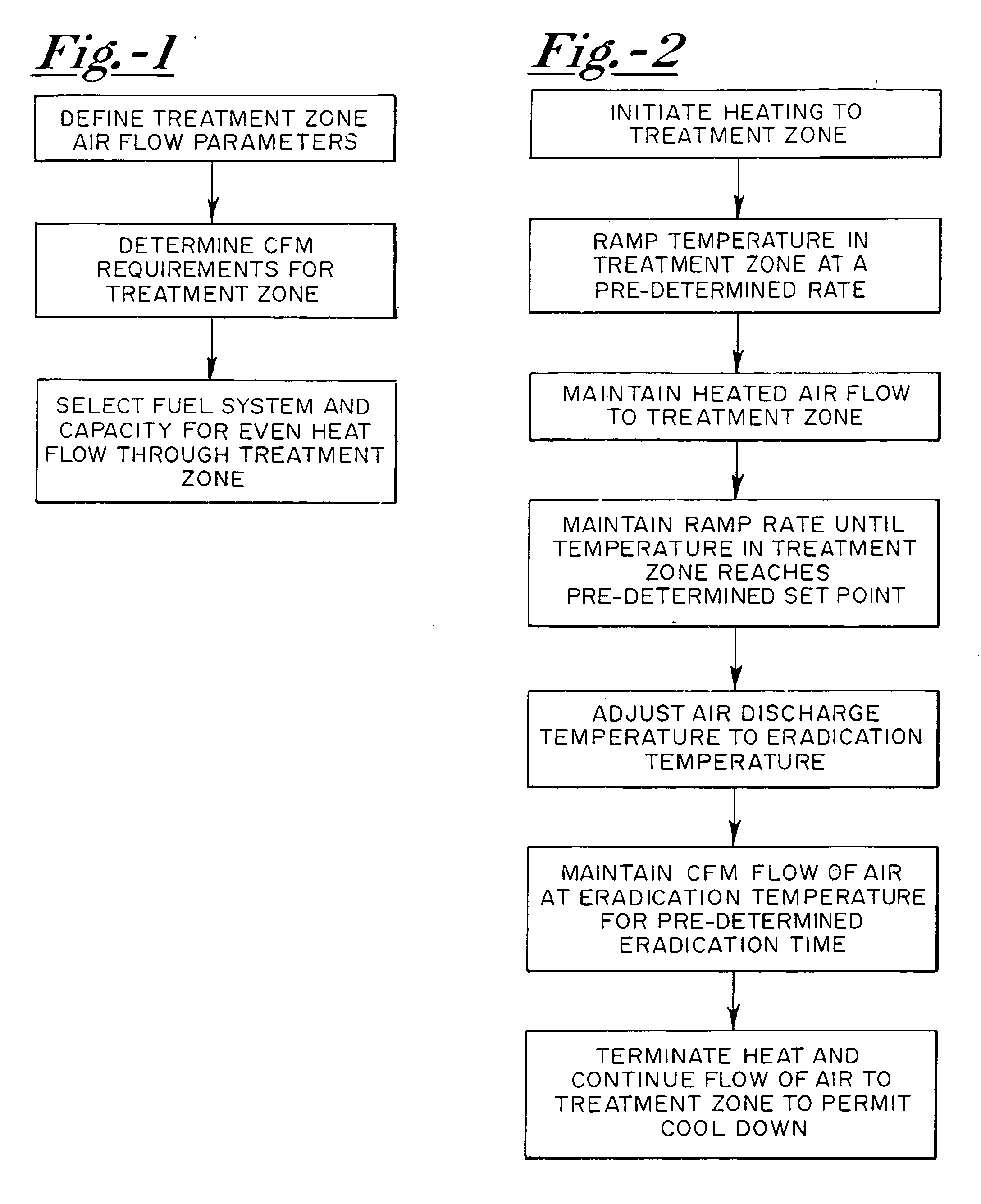

[0021] In accordance with the preferred embodiment of the present invention, the thermal treatment of a zone for extermination of pests is undertaken as follows. It is believed that the recitation of steps set forth below will enable those of skill in the art to readily and effectively practice the technique.

Treatment Zone Defined

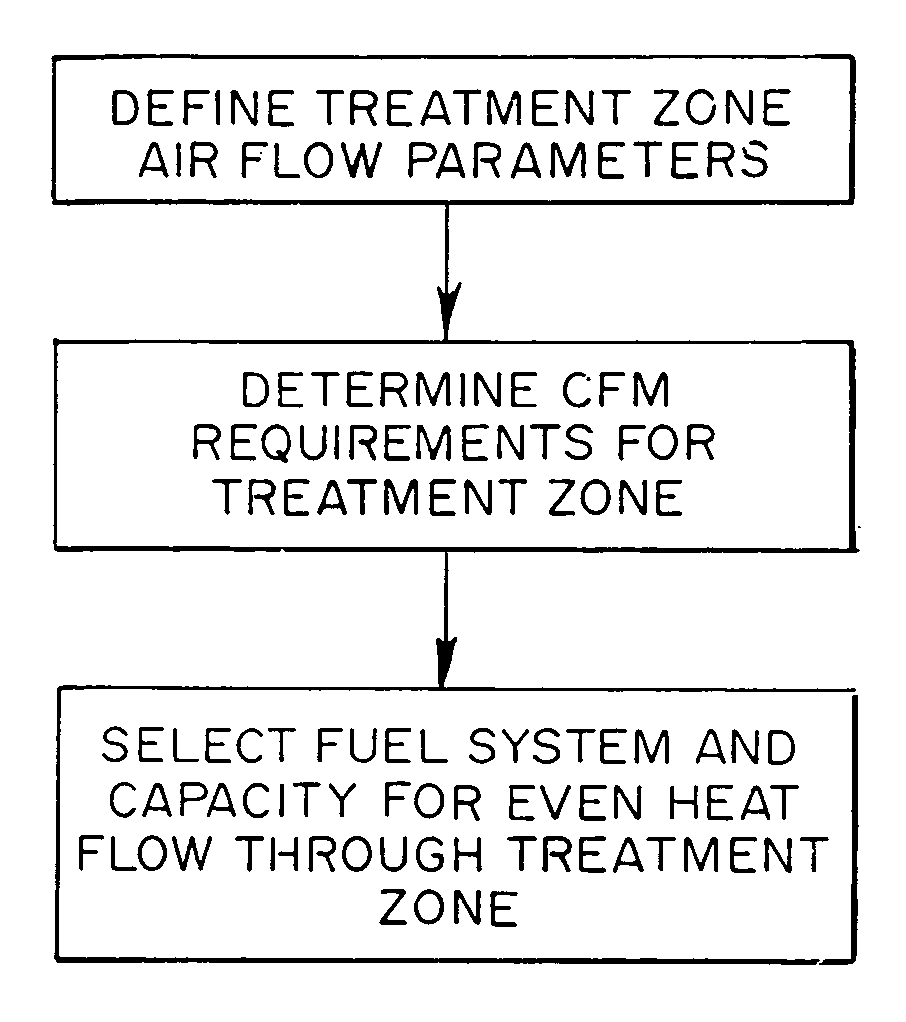

[0022] The dimensions, type of structure, as well as area of structure for heat treatment is analyzed and determined. This determination enables the technician to establish some basic guidelines for the equipment necessary to effectively handle the procedure. Accordingly, the nature of the heat source and fuel supply is determined, along with the equipment installation factors.

[0023] The step of defining treatment zone air flow is then undertaken with respect to heat movement, air distribution, placement of the equipment being utilized, and desired locations for heated air inlet and discharge. This step may generally be characterized as the determination...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com