Self contained dissolved air flotation system

a self-contained, flotation system technology, applied in sedimentation settling tanks, other chemical processes, separation processes, etc., can solve the problems of affecting the quality of water, and affecting the use of septic tanks,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

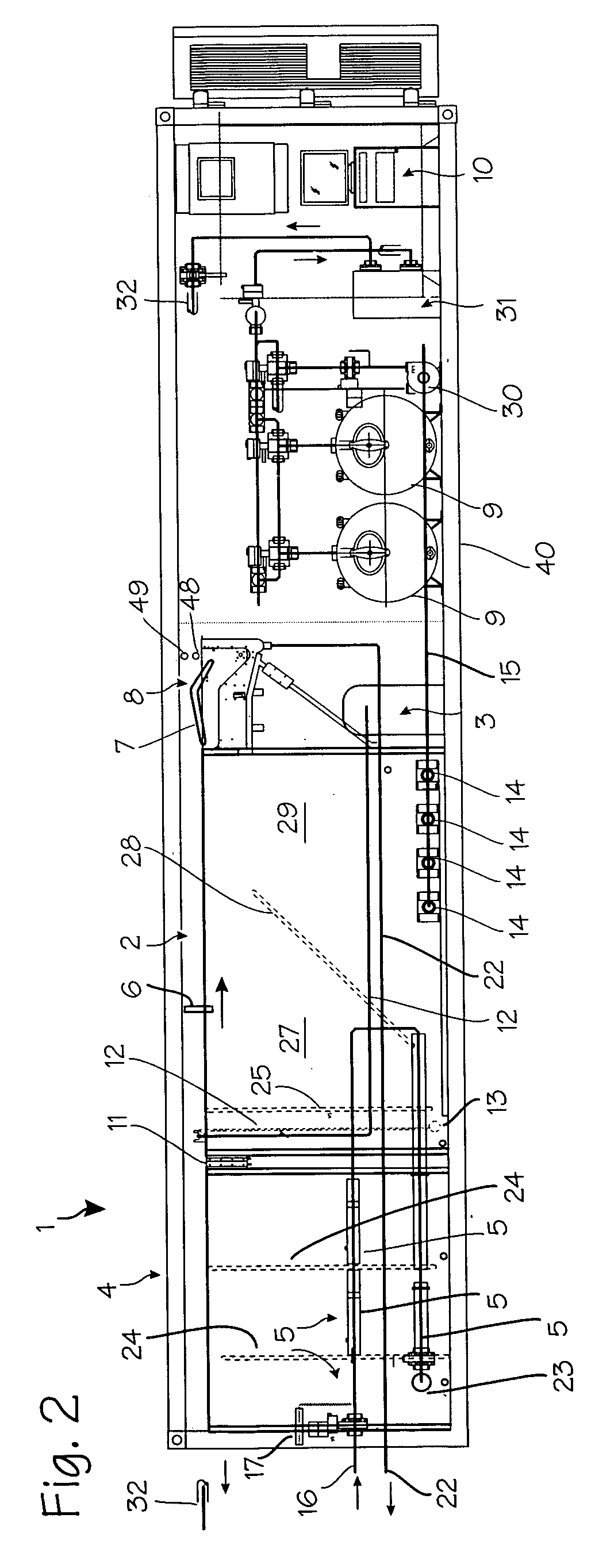

[0012]FIGS. 1 and 2 illustrate the dissolved air flotation system 1. The major components of the dissolved air flotation system include a flotation tank 2 and a dissolved air supply 3, a flocculation tank 4 and influent / coagulant mixing system 5, a skimmer assembly 6, a waste collecting system that includes a beach 7 and waste transport system 8, post-treatment filtration tanks 9, and a control room 10.

[0013] The flotation tank 1 is used to mix influent water with a stream of water containing a large amount of dissolved air. The bubbles produced from the dissolved air attach to flocculent (particles suspended in the water which have aggregated into clumps or masses in the flocculation tank) grown in the influent water and floats to the top of the tank where it collects in a thin layer referred to as float, sludge, or scum. The flotation tank is supplied with unpurified influent from the flocculation tank, flowing over weir 11 (as influent is pumped into the flocculation tank, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com