Modular fluid purification system and components thereof

a fluid purification system and module technology, applied in the field of fluid purification system, can solve problems such as system leakage, unsanitary conditions, and prone to leakage, and achieve the effect of easy change-out of system components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The purification system of the invention will be described with respect to certain specific embodiments, which description is intended to aid in understanding of the invention, and not to limit the scope of the claims.

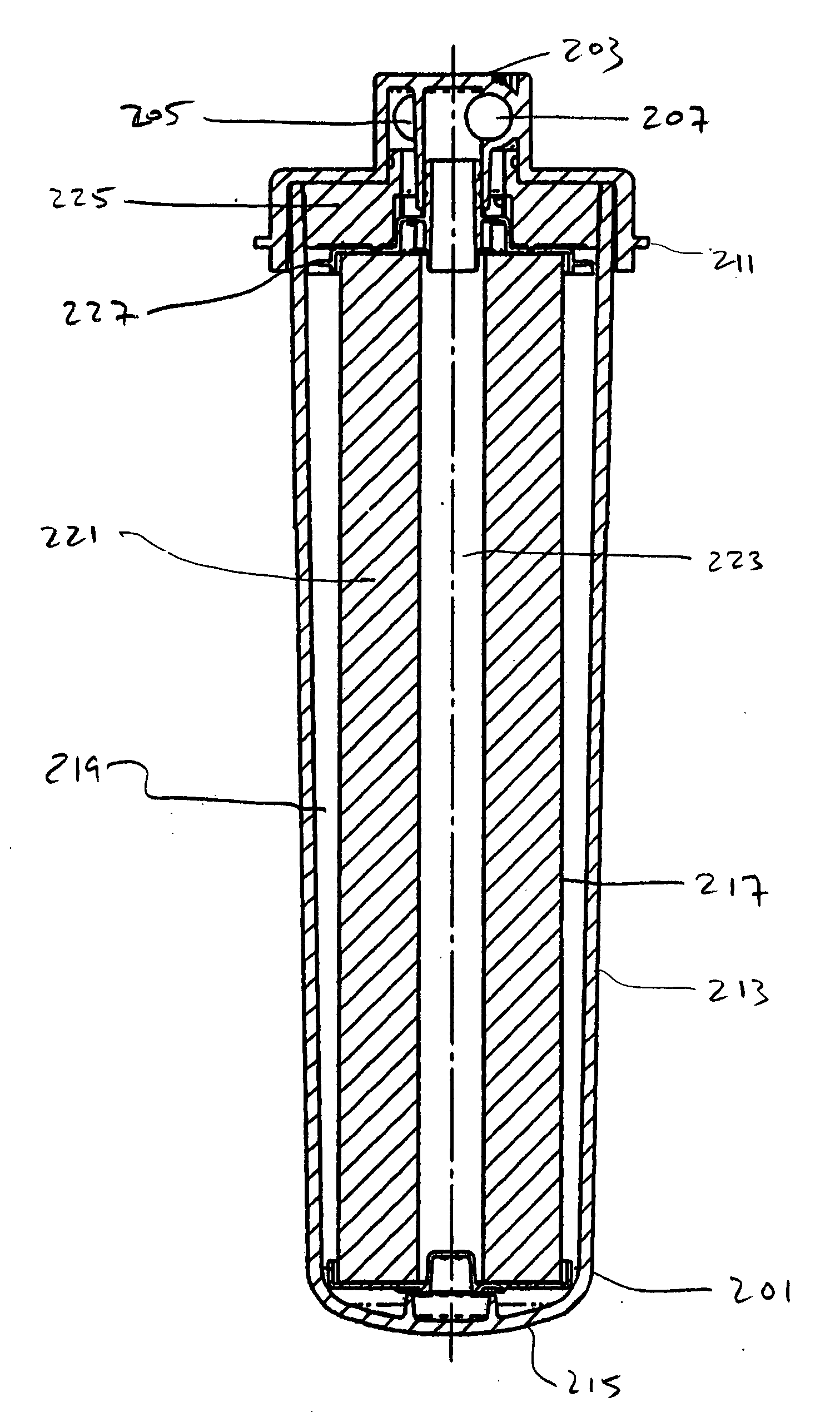

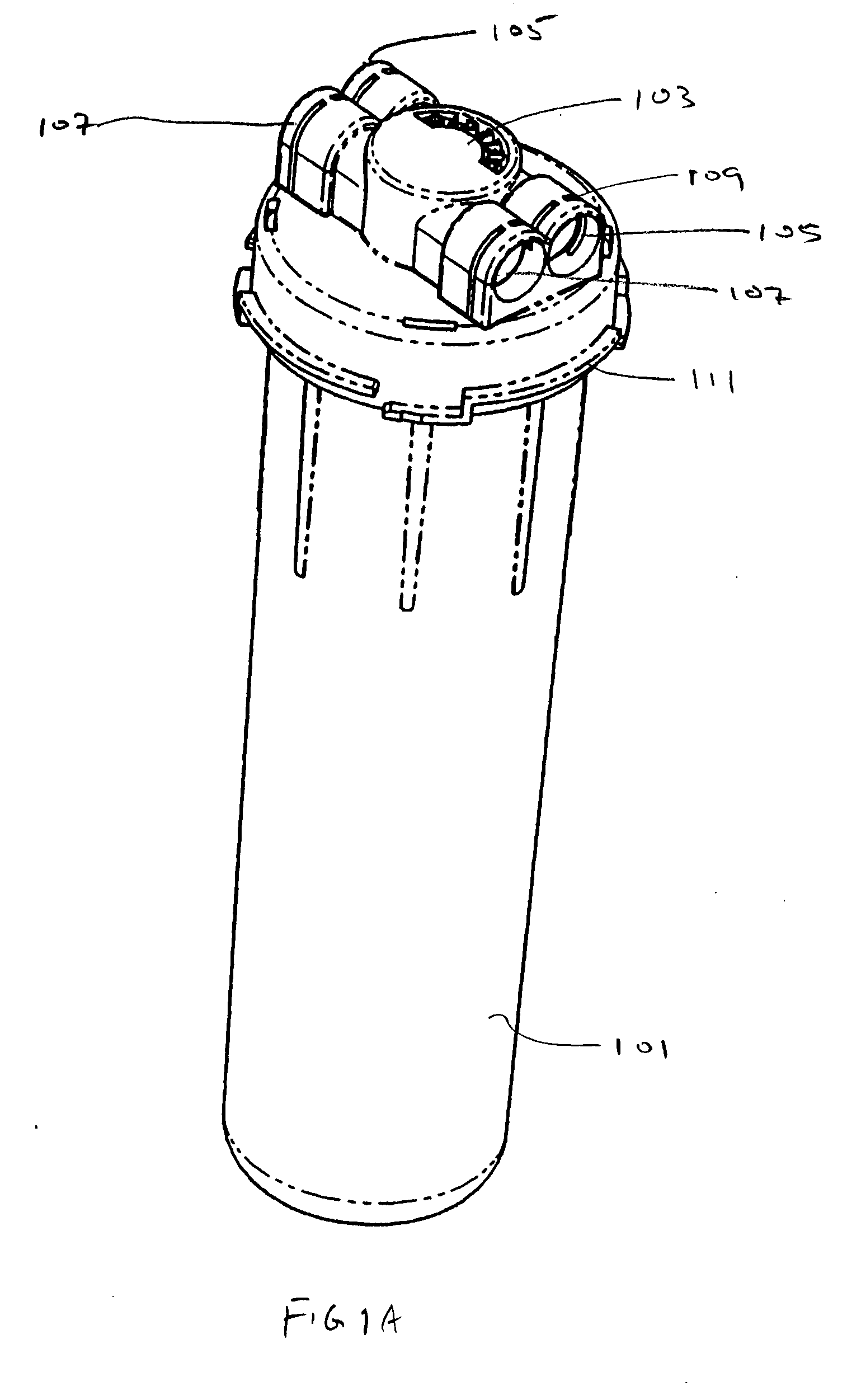

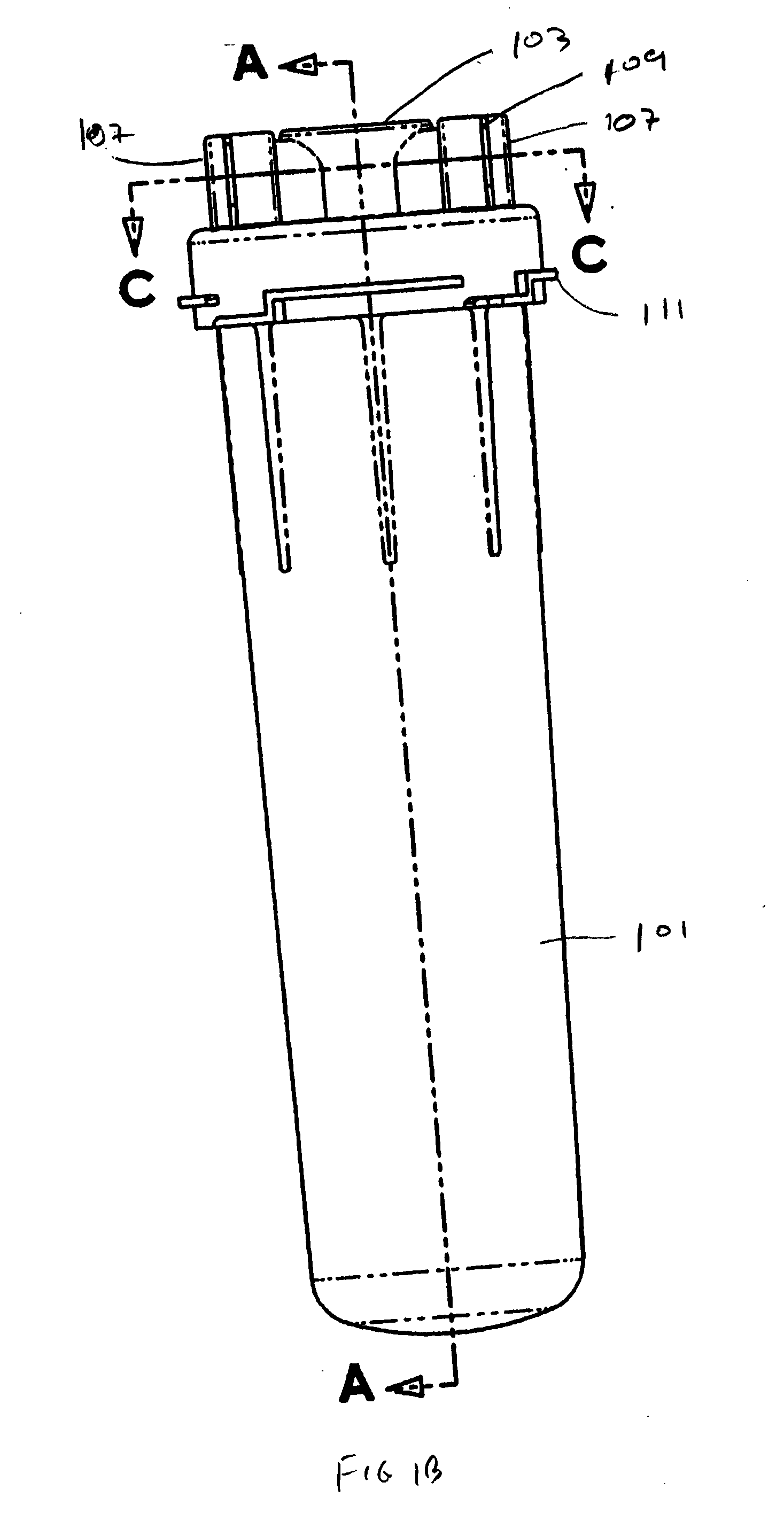

[0052]FIG. 1A is a perspective view, and FIGS. 1B and 1C are side and front plan views, respectively, of one embodiment of the purification system of the invention. Sump 101 is adapted to contain a purification media cartridge (not shown), and is typically made of polymer (such as polyolefins (e.g., LDPE, HDPE, polypropylene, polybutylene, etc.), polyamides (e.g., nylons), polyesters (e.g., PET), and the like) or other lightweight, disposable material. The sump is designed to be disposable along with the purification media cartridge, so that maintaining the purification system does not require disassembly of the media from the sump, handling of the media, etc. This eliminates the need for maintenance personnel to handle unsanitary, contaminated media. Sump 101 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure drop | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| circumferential velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com