An enhanced heat transfer tube with discrete bidirectionally inclined ribs

a heat transfer tube and bidirectional inclined technology, applied in tubular elements, corrosion prevention, coatings, etc., can solve the problems of high cost of tube manufacturing, low efficiency, bulky and material-cost of ordinary shell and tube heat exchangers using circular tubes, etc., to achieve enhanced heat transfer, low additional pressure loss, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

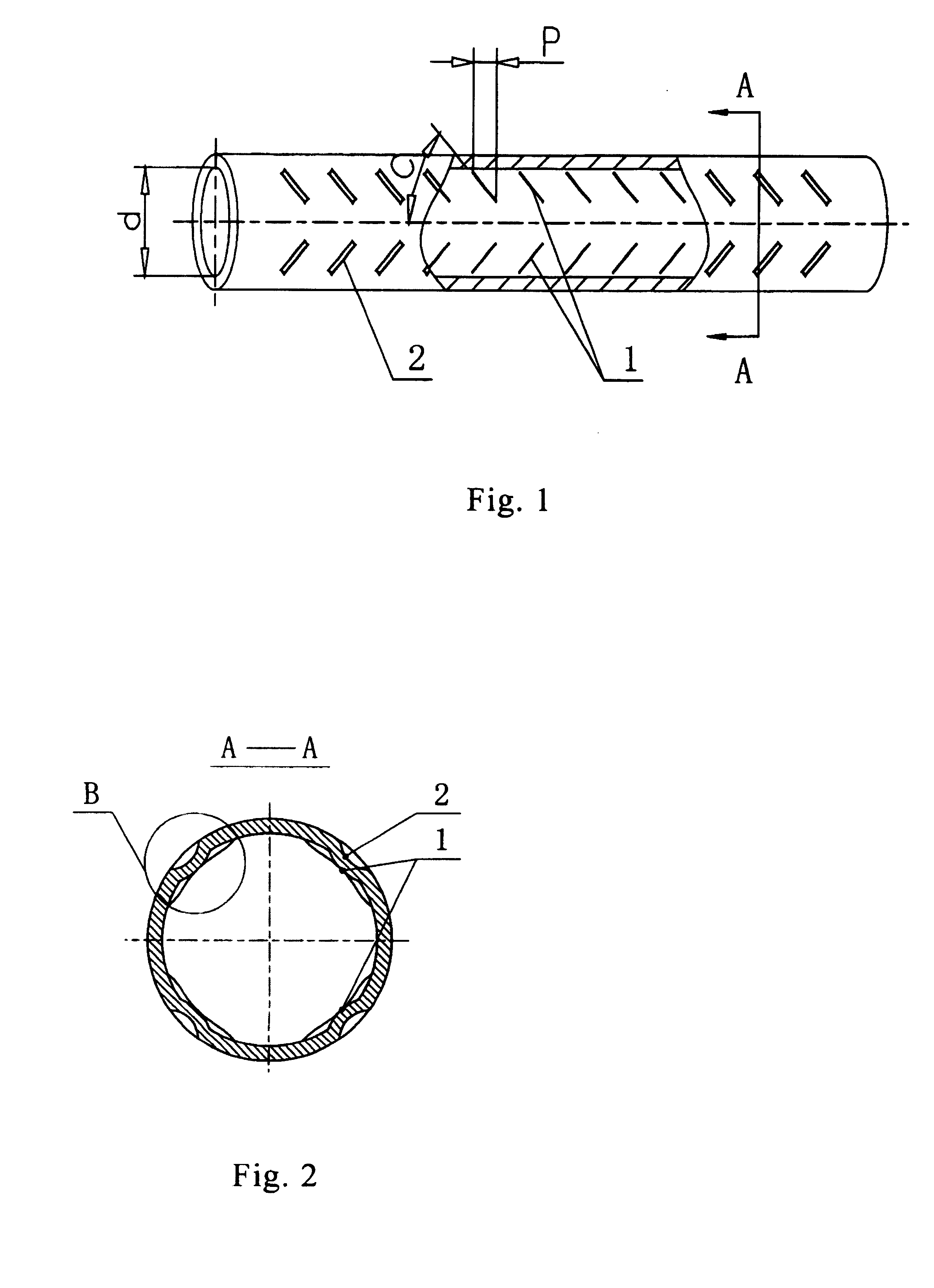

[0017]FIG. 1 shows the structure of a DBIR-tube of the present invention. The inner surface of the tube is provided with a plurality of discrete, two-direction helical protrusions (named as internal discrete double helical ribs or internal discrete bidirectionally inclined ribs). The outer surface of the tube is provided with a plurality of discrete double helical grooves.

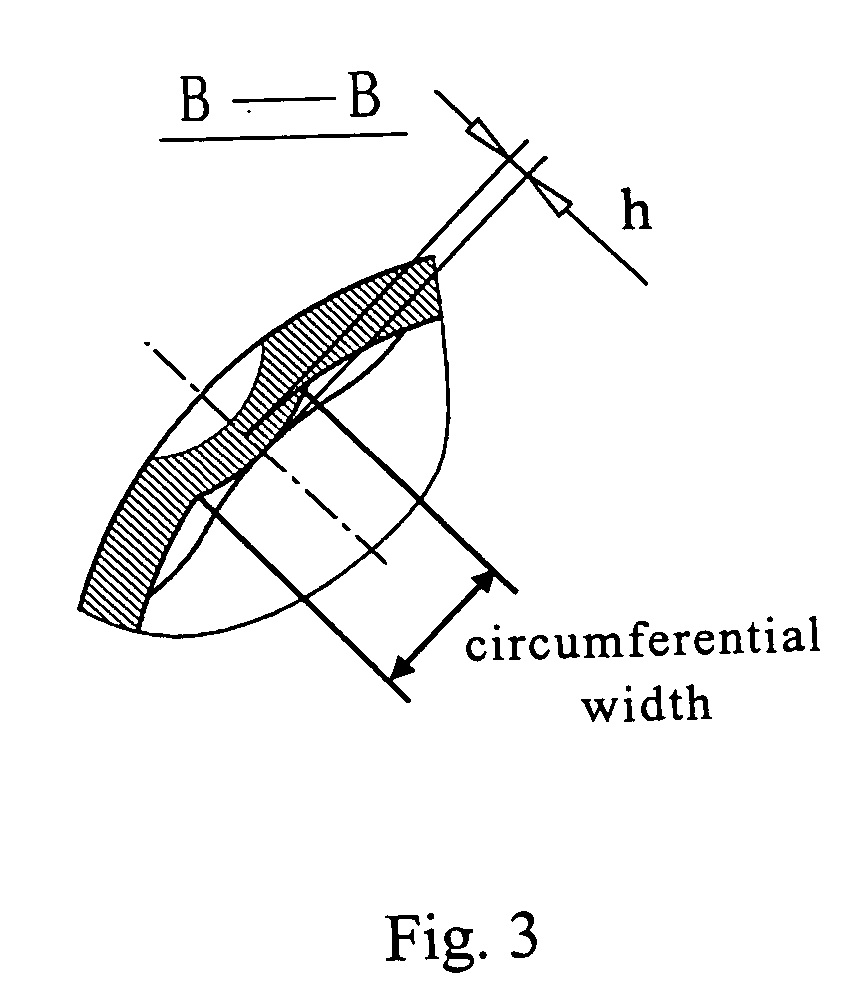

[0018] In FIGS. 1 and 2, reference numeral 1 designates the discrete double helical ribs, and reference numeral 2 designates the discrete double helical grooves, with the helical ribs and the corresponding helical grooves being formed simultaneously during processing. In FIG. 1, reference sign “d” designates the hydrodynamic inner diameter of the tube, reference sign “P” designates the axial length of each internal inclined rib, and reference sign “C” designates the helical angle of the internal inclined ribs. In FIG. 3, reference sign “h” designates the height of the internal inclined ribs. Th...

second embodiment

The Second Embodiment

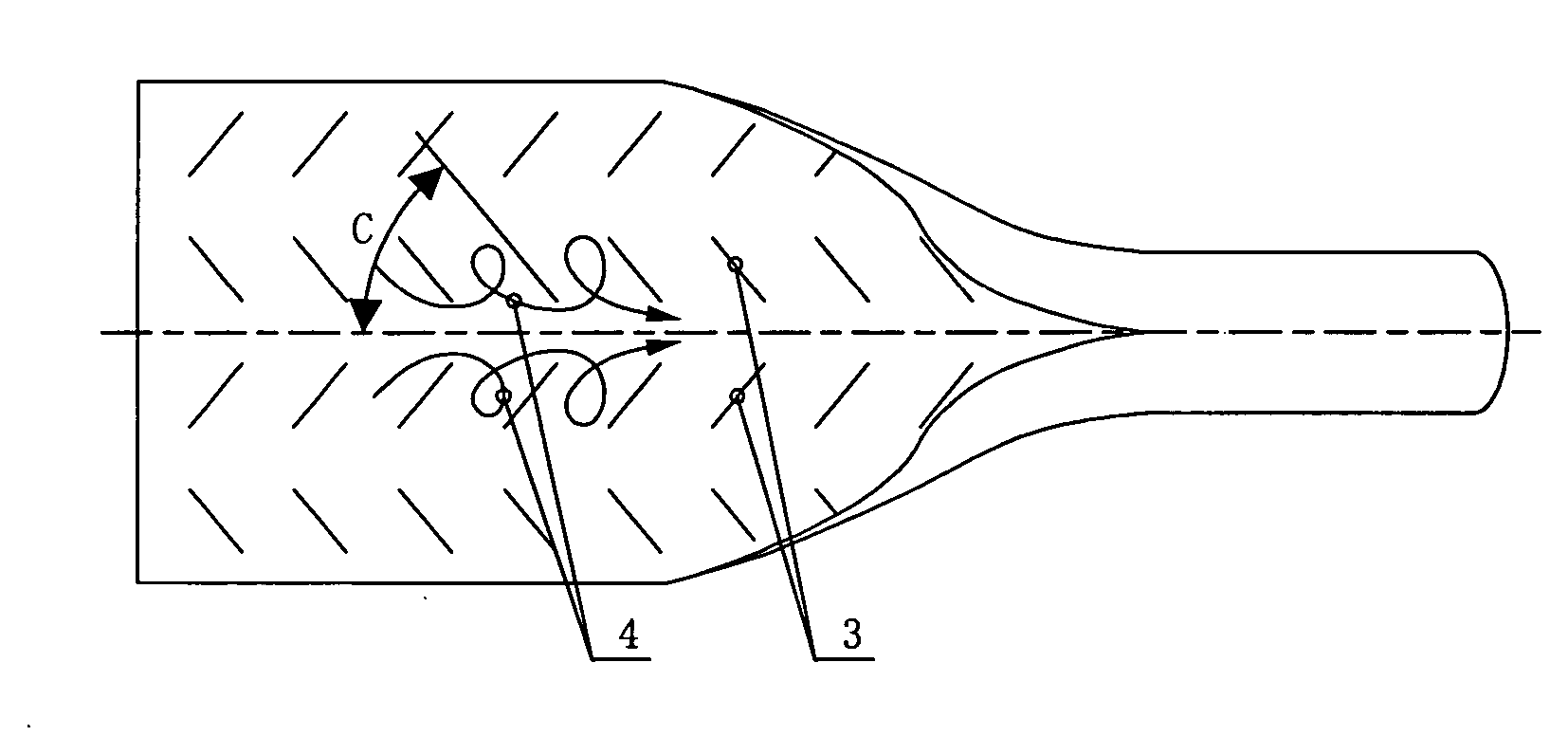

[0019]FIG. 4 shows the structure of another DBIR-tube of the present invention in a circumferentially part-deployed schematic view. The inner surface of the tube is provided with a plurality of discrete, two-direction helical protrusions (discrete bidirectionally inclined ribs or discrete double inclined ribs). The outer surface of the tube is smooth, without any protrusion or groove.

[0020] In FIG. 4, reference numeral 3 designates the discrete bidirectionally inclined ribs, which are symmetrical disposed. Each pair of inclined ribs, composed of an inclined rib which is orientated in a right hand declining direction and a circumferentially neighboured inclined rib which is orientated in a left hand declining direction, form a vortex generator. In each cross-section of the tube, there are two vortex generators formed by four inclined ribs. In FIG. 4, reference sign “C” designates the helical angle of the internal inclined ribs, and C≈±50°, wherein the positive s...

third embodiment

The Third Embodiment

[0021]FIG. 5 shows the structure of yet another DBIR-tube of the present invention in a circumferentially part-deployed schematic view. The inner surface of the tube is provided with a plurality of discrete, two-direction helical protrusions (bidirectionally inclined ribs). The outer surface of the tube is provided with a plurality of discrete double helical grooves.

[0022] In FIG. 5, reference numeral 5 designates the discrete double helical ribs which are asymmetrically arranged, and reference numeral 6 designates the discrete double helical grooves which are also asymmetrically arranged. On the inner surface, each pair of inclined ribs, composed of an inclined rib which is orientated in a right hand declining direction and a circumferentially neighboured inclined rib which is orientated in a left hand declining direction, form a vortex generator. Within a small circumferential segment of the tube, which has an axial length of less than 0.5 d, there are three v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com