Vacuum sterilization process and devices

a sterilization process and vacuum technology, applied in the field of sterilization process and operational devices, can solve the problems of high energy consumption of systems, high risk of re-contamination, and material contamination during the process, and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

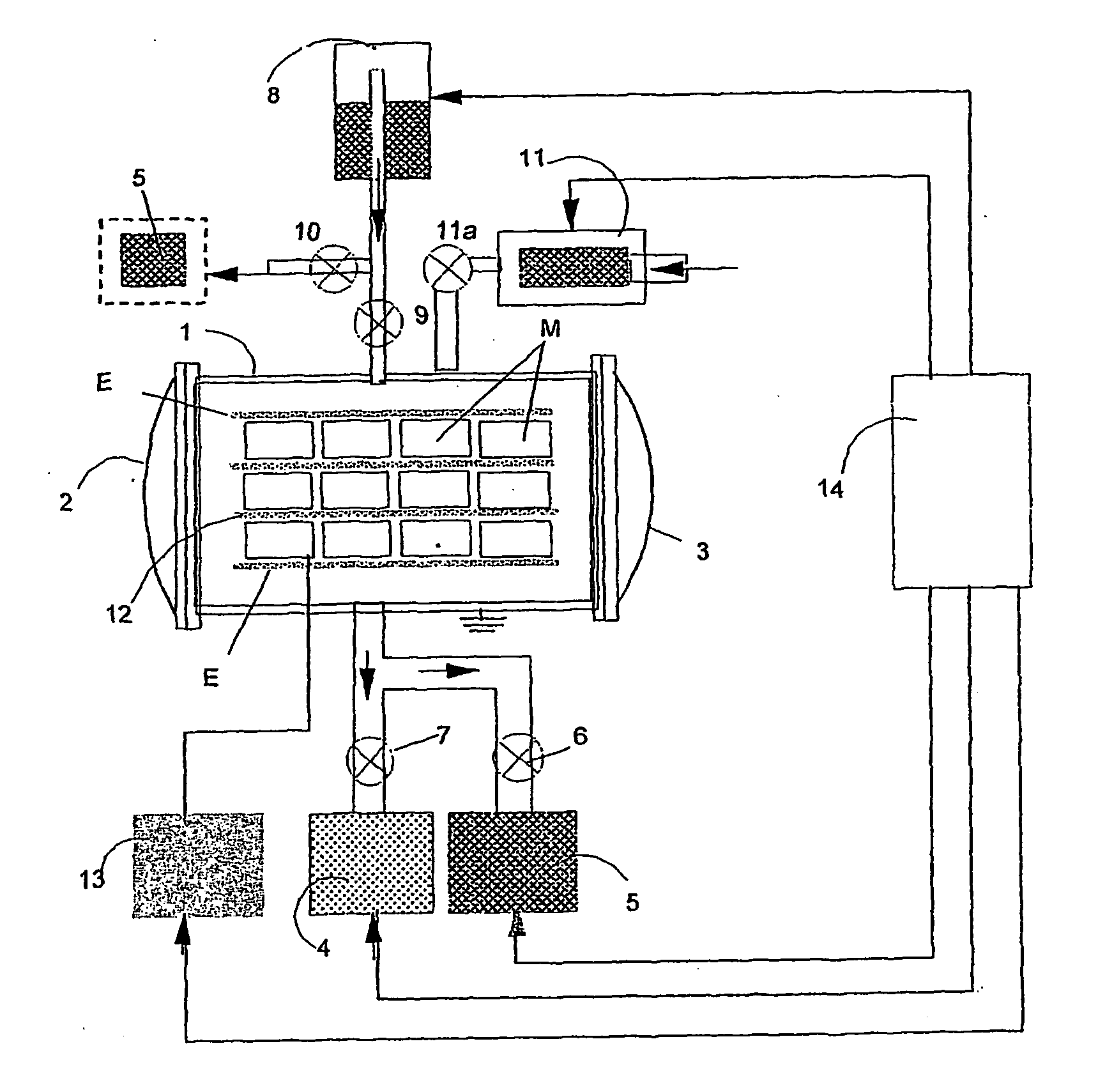

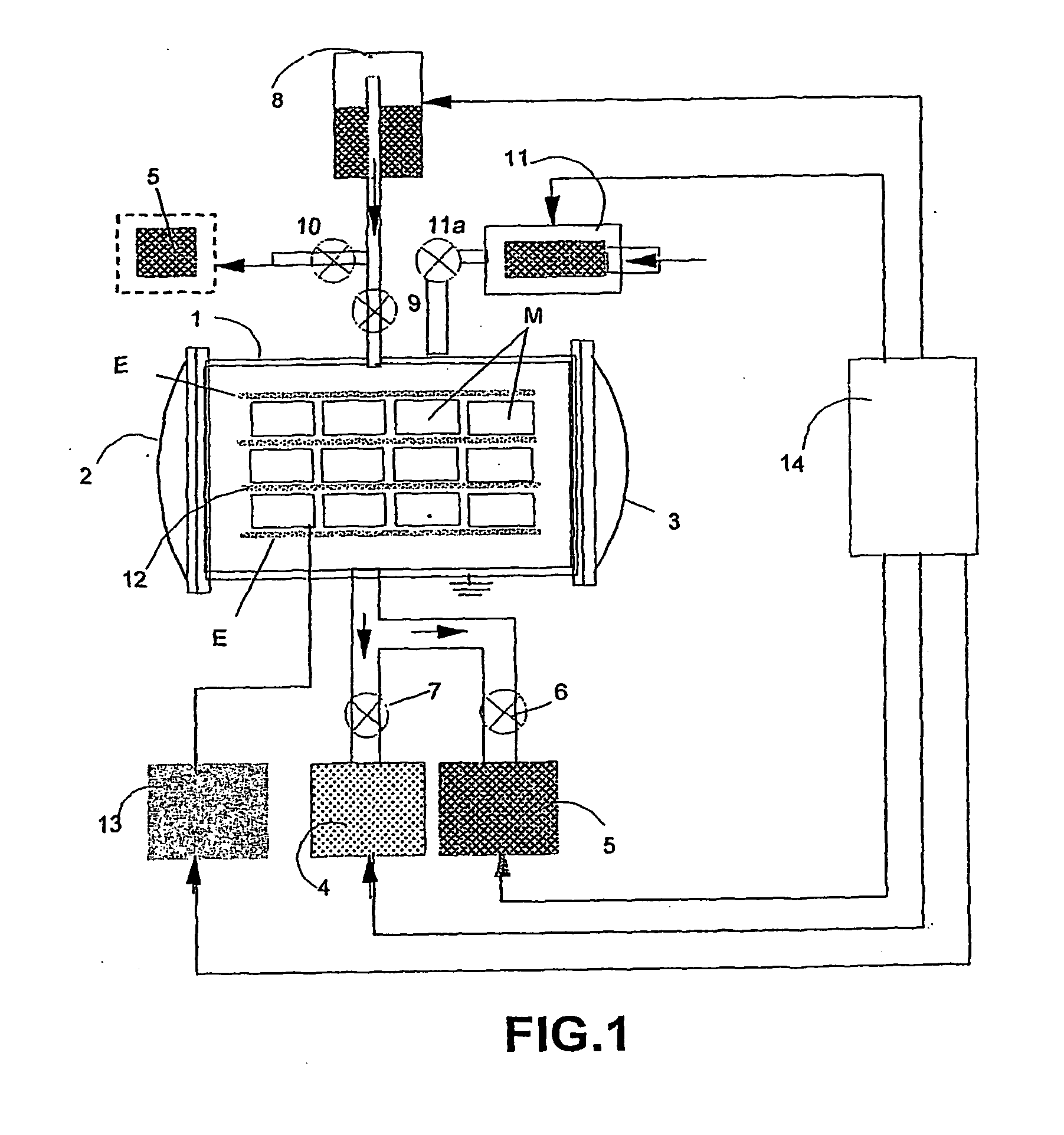

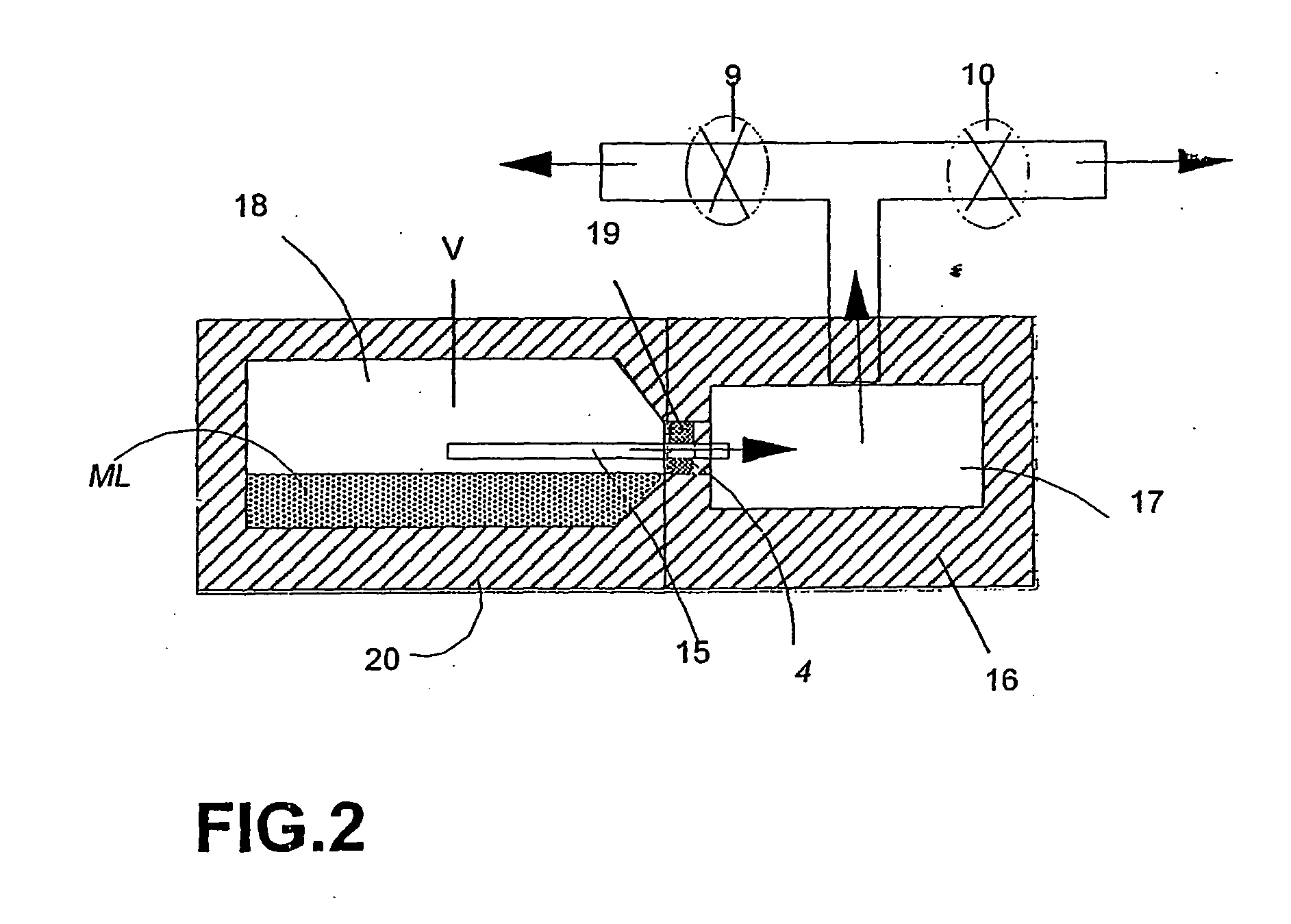

[0045] With reference to the drawings, the present invention relates to a vacuum sterilization process with the application of steam of a mixture of peracetic acid with hydrogen peroxide and residual gas plasma from atmospheric air, excited by pulsed electrical discharge; to operational devices and methods used in the sterilization process, the process and devices being exemplified and illustrated in particular in a diagrammatical manner in FIG. 1, which comprises the sterilization of surgical and associated articles, and products in general (M), with the arrangement that, at the beginning of the sterilization process, the materials which are to be sterilized are arranged and subjected to a vacuum in a stainless steel chamber (1), with the option of one or two doors (2) and (3); connected to the chamber (1) is a vacuum system consisting of at least one mechanical vacuum pump (4) and at least one ring-type liquid vacuum pump (5), connected in parallel and linked to the said chamber b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com