Heat exchange unit and heat exchanger using the heat exchange unit

a heat exchange unit and heat exchanger technology, applied in indirect heat exchangers, lighting and heating apparatuses, tubular elements, etc., can solve the problems of high manufacturing cost, high manufacturing cost, and difficult processing, and achieve low pressure loss of exhaust, simple structure, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

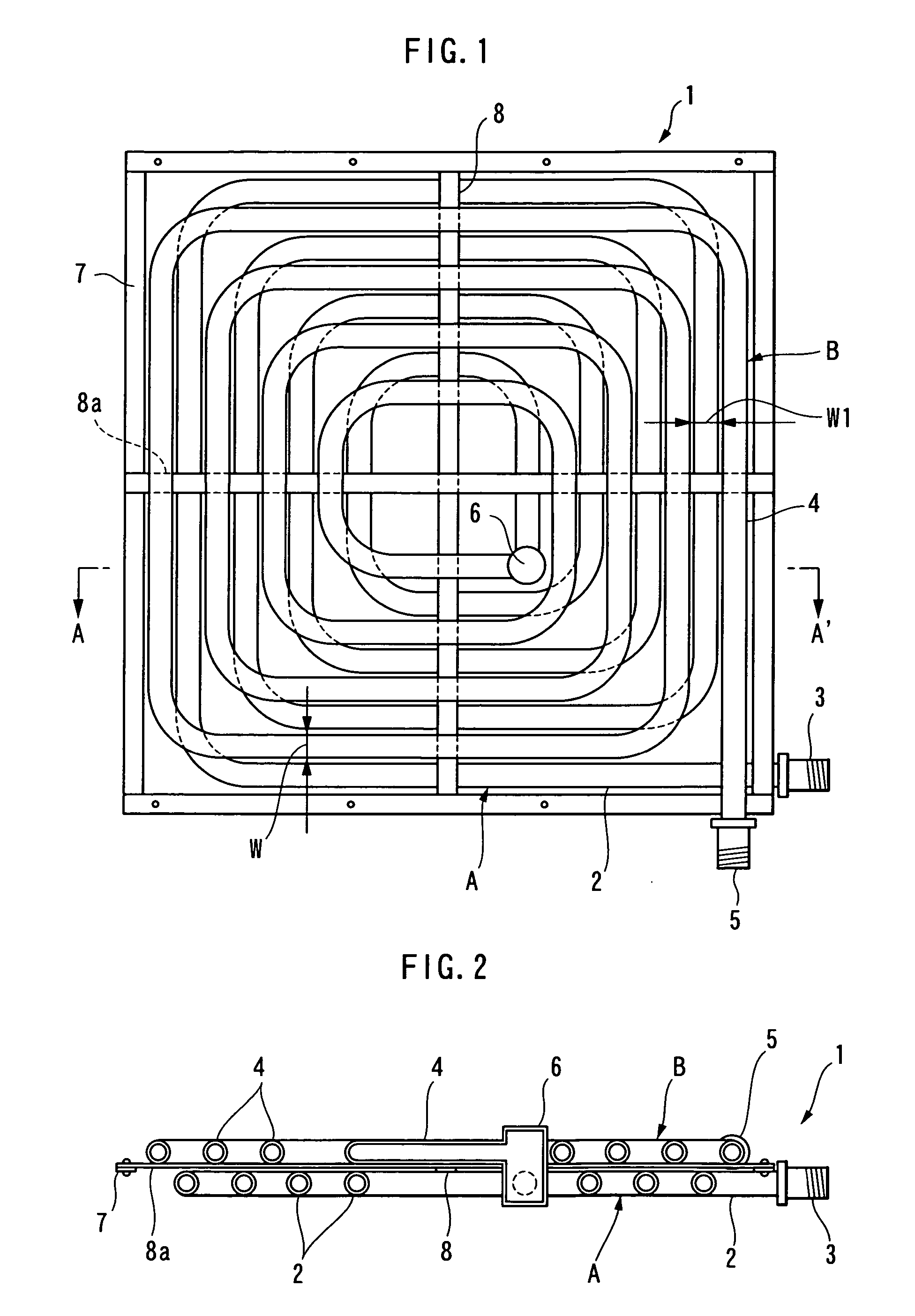

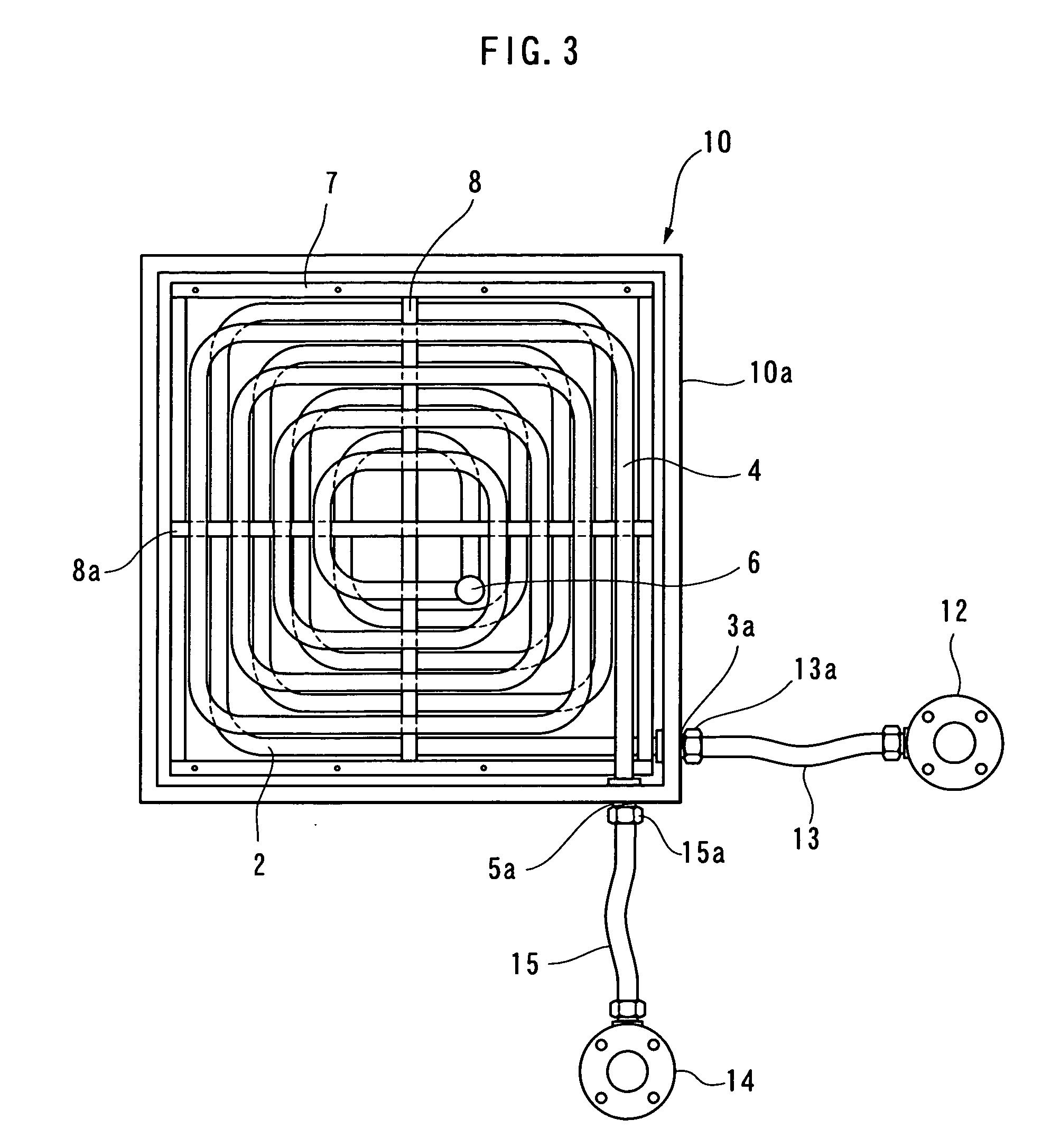

[0055]FIG. 1 is a front view showing a heat exchange unit 1 according to the invention of Claims 1 to 3. FIG. 2 is a sectional view of FIG. 1 taken along line A-A′. FIG. 3 is a front view of a heat exchanger. FIG. 4 is a diagram showing a structure in which the heat exchanger according to the present invention is attached to an exhaust duct to collect latent heat.

[0056] Reference numeral 1 denotes a heat exchange unit. The heat exchange unit 1 includes a unit element A composed of a heat exchanger tube 2 and a unit element B composed of a heat exchanger tube 4. The heat exchanger tube 2 has a fluid inlet 3 at an outer end thereof and is coiled toward the center with predetermined gaps W between successive windings. The heat exchanger tube 4 has a fluid outlet 5 at an outer end thereof and is coiled toward the center with predetermined gaps W1. The heat exchanger tubes 2 and 4 of the unit elements A and B, respectively, are connected to each other with a connection pipe 6 at the inn...

example 2

[0063] In Example 2, a heat exchanger tube 2 is coiled in a single plane. The coiled heat exchanger tube 2 may be used by itself. Alternatively, similar to Example 1, a heat exchange unit 1 may be obtained by combining unit elements A and B together. In FIG. 5, reference numeral 6 denotes a connection pipe which connects heat exchanger tubes 2 of the unit elements A and B to each other at a central position. FIG. 6 shows a heat exchanger 10 obtained by arranging a plurality of heat exchange units 1 having the above structure. In FIG. 6, reference numeral 18 denotes an inlet / outlet header in which a fluid inlet and a fluid outlet are combined. Similar to Example 1, fluid from the header 18 enters, for example, the element A at an outer end of the element A, flows into the element B through the connection pipe 6, and returns to the header 18 from the element B at the outer end of the element B.

[0064] Also in Example 2, the heat exchanger 10 may be designed to have a desired number of...

example 3

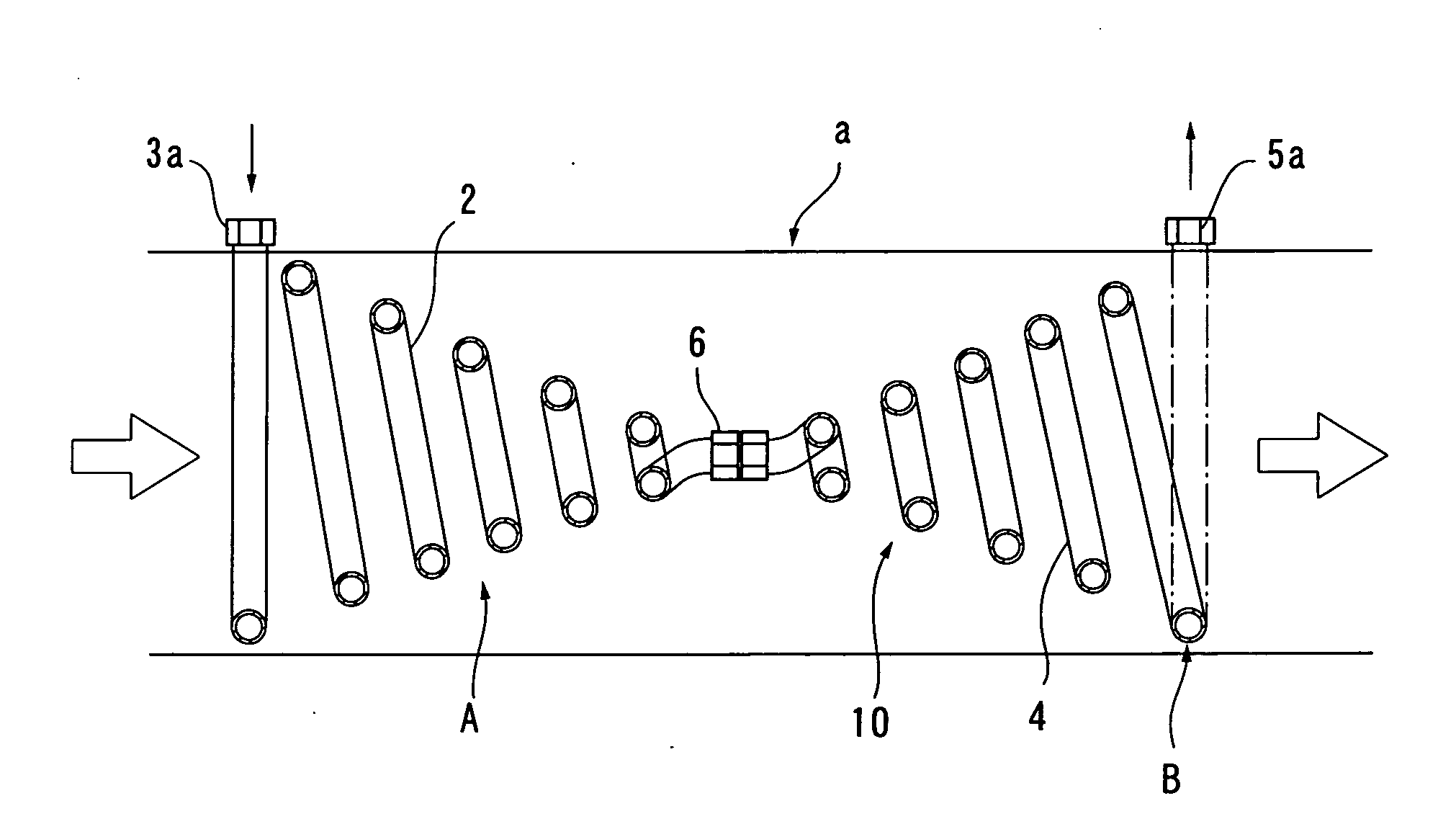

[0065] Example 3 corresponds to the invention of Claim 4. As shown in FIG. 7, Example 3 differs from Examples 1 and 2 in that heat exchanger tubes 2 and 4 are helically coiled into a conical shape and an inverted conical shape, respectively, instead of being coiled in a single plane. An element A and an element B having the conical and inverted conical shapes are connected to each other with a connection pipe 6 to form a heat exchange unit 1. The heat exchange unit 1 is installed in, for example, a flue a.

[0066] When a plurality of heat exchange units 1 having the above structure are combined, the heat exchange units 1 may be arranged along the longitudinal direction thereof Such a structure is advantageous in increasing a heat transfer area while keeping pressure loss in the flue a as low as possible when the diameter of the flue a is small. In addition, pressure loss of fluid which flows through the heat exchanger tubes 2 and 4 is also reduced and the performance is effectively i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com