Method and device for non-contact sampling and detection

a non-contact sampling and detection technology, applied in the direction of particle separator tube details, instruments, separation processes, etc., can solve the problems of limited screening to only a small portion of samples, high dependence on trained operators, and inability to carry out the technique for applications that require portability, so as to achieve the effect of maximum sample ion production and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

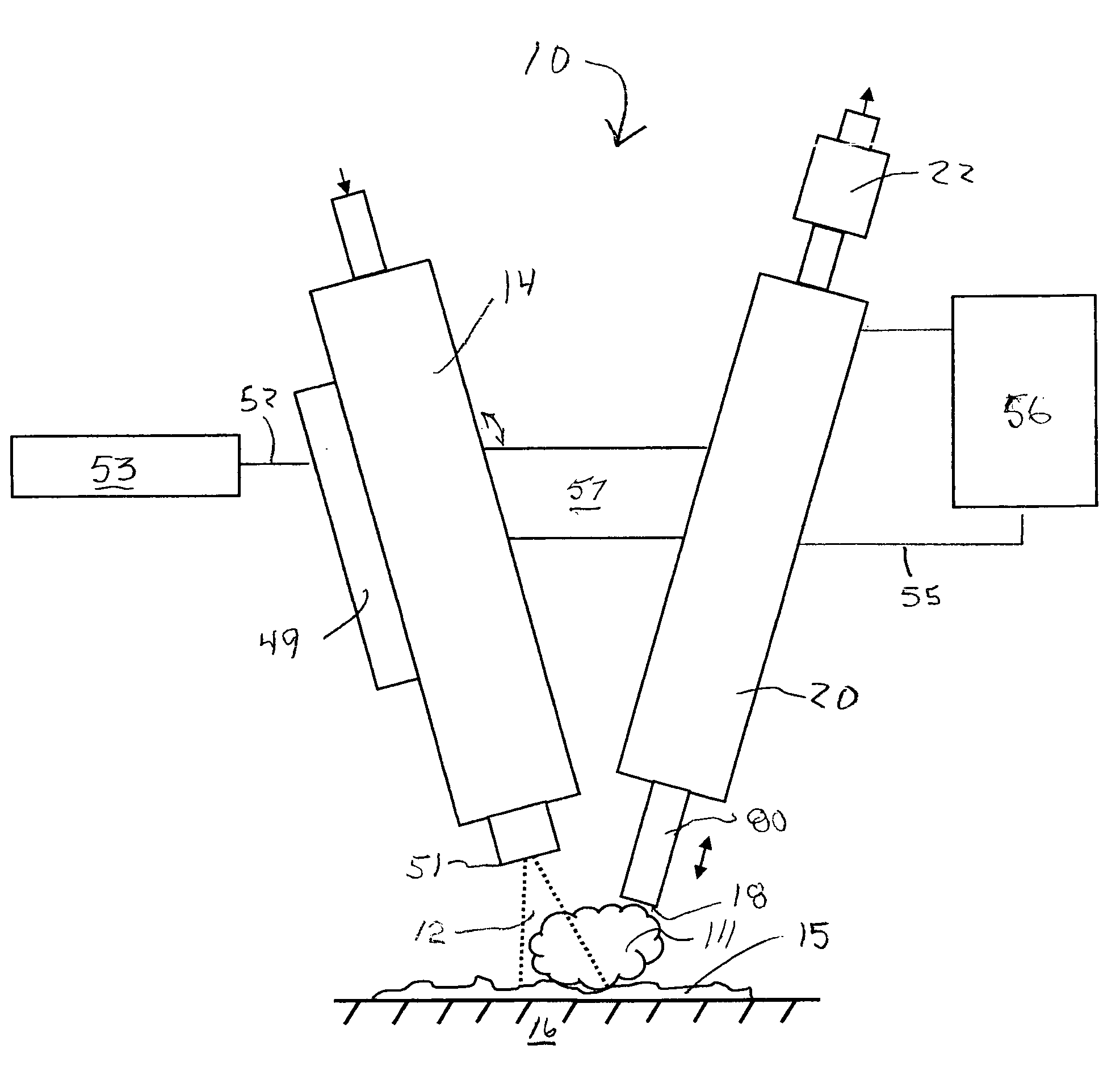

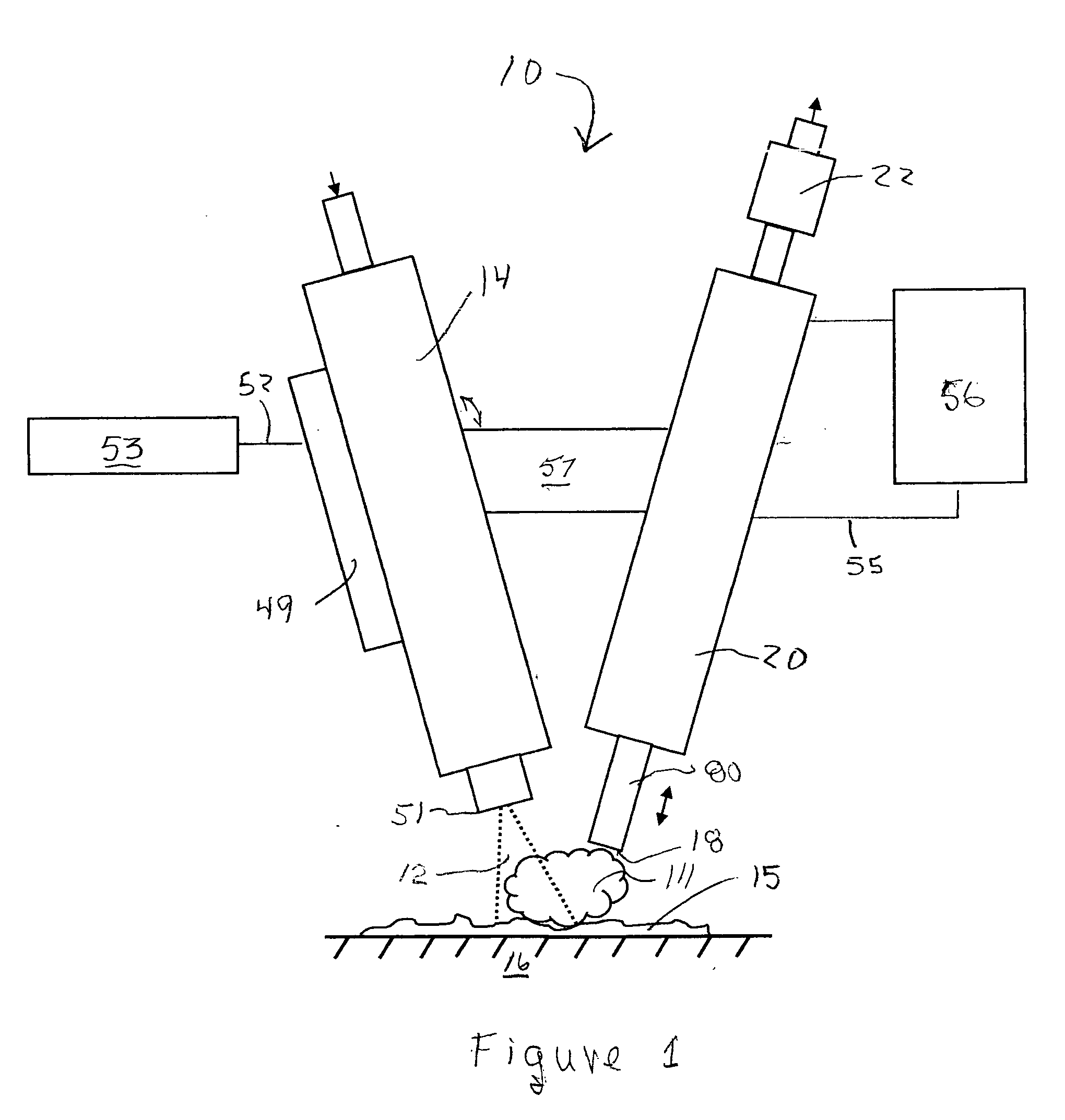

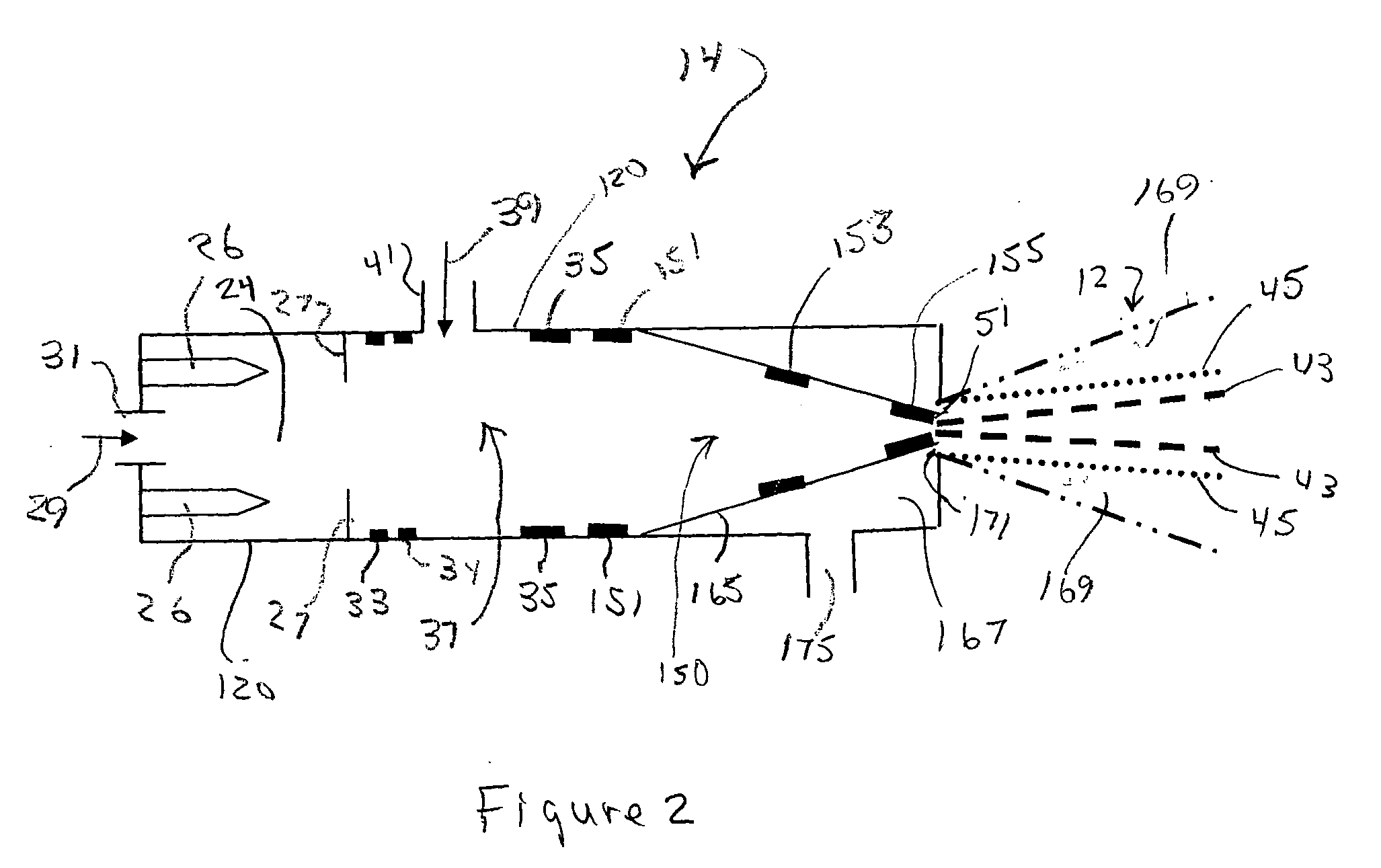

[0039] In a broad sense, this invention can be viewed as a method and means for conducting a three-step energy transfer process that may then be followed by an analytical procedure. Energy is applied to a first gas by means of a corona discharge, forming ions and other energetic species of that gas. The energetic species of the first gas then transfer energy to a second gas, which must have at least one component with an ionization potential, or ionization energy, less than that of the energetic species of the first gas so as to produce reactant ions of the second gas. Those reactant ions are caused to impact upon a surface, reacting with chemicals or other materials on the surface to produce analyte ions that are collected, detected and identified.

[0040] A significant advantage of this downhill energy flow is that it utilizes energy from an inexpensive, relatively uncontrolled high energy source (corona discharge) and converts it into energetic species that provide a “soft” ioniza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com