Seamless steel tubes and pipes for use in oil well

a technology of seamless steel and oil well, applied in the field of seamless steel tubes and pipes, can solve the problems of difficult to obtain stable mechanical strength and inability to realize stable mechanical strength, and achieve excellent mechanical strength. the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

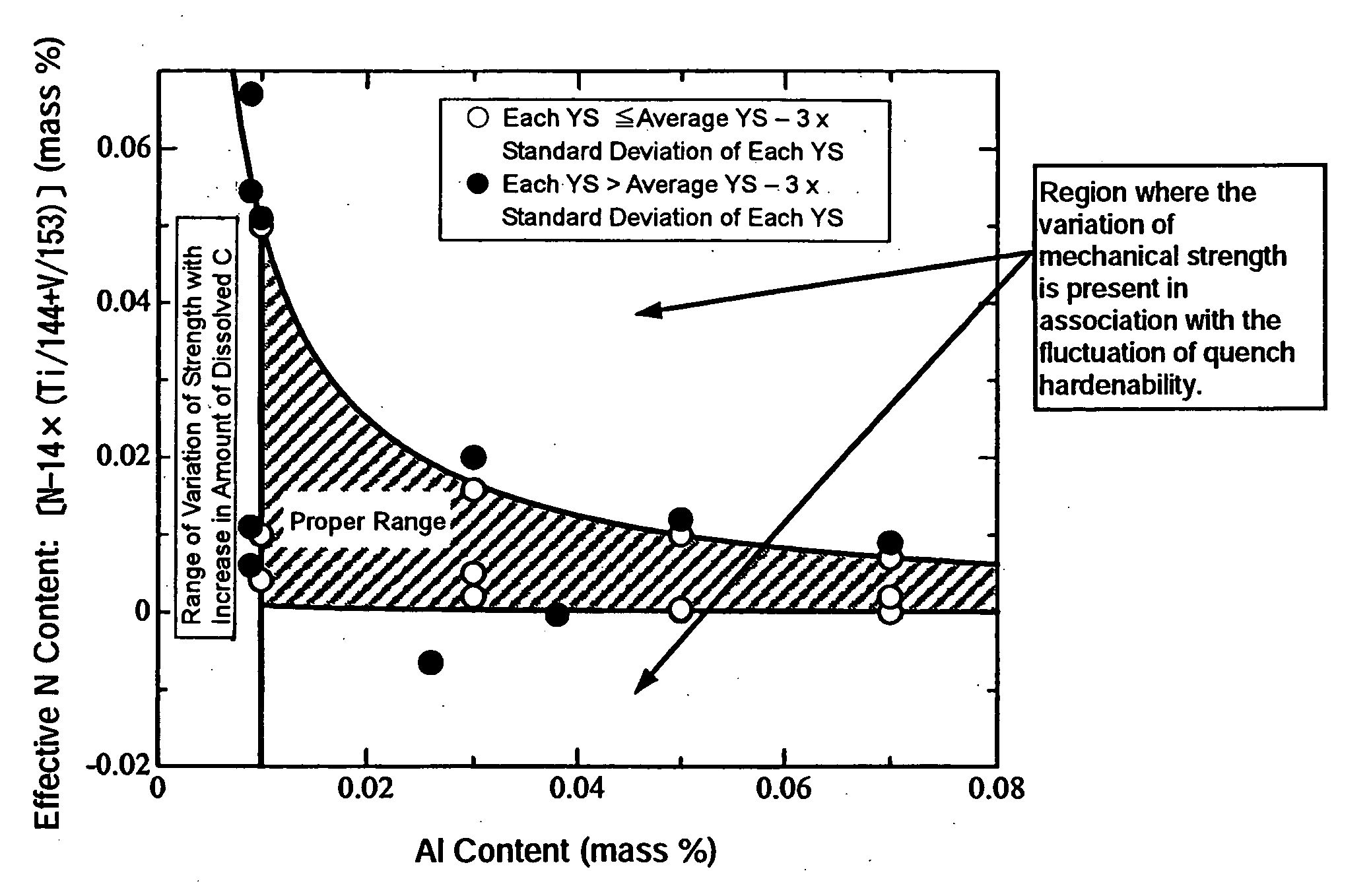

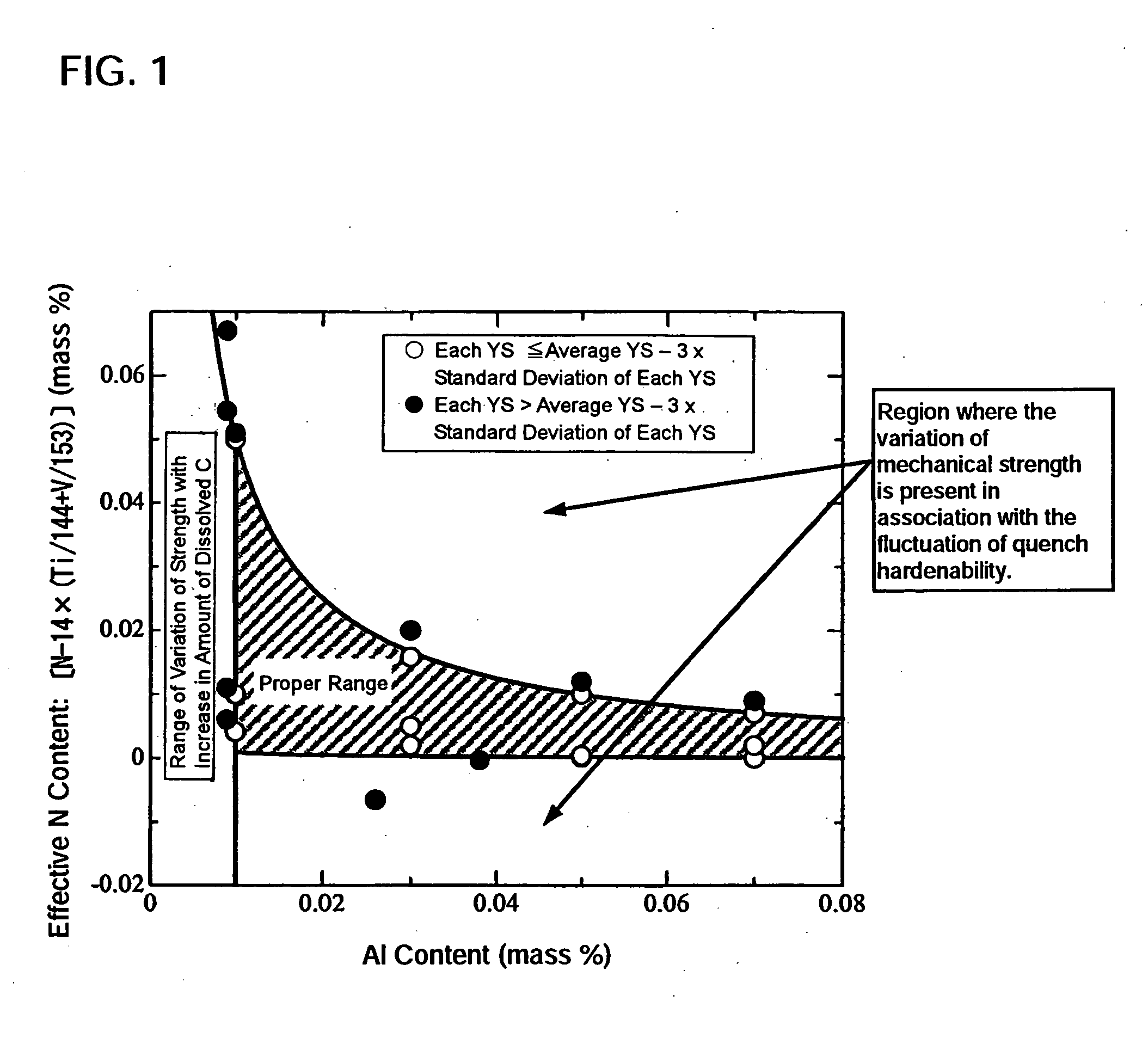

Image

Examples

examples

[0061] In order to confirm the effect of seamless steel tubes for use in oil well according to the present invention, following tests were carried out and the results were evaluated.

[0062] The billet of 225 mm in diameter was made for each of 22 grades of test steel whose chemical compositions are shown in Tables 1 and 2. Then, the billet was heated at 1250° C., and subjected to Mannesmann Mandrel Tube Making Process to obtain a seamless steel tube of 244.5 mm in outside diameter with 13.8 mm in thickness. Thereafter, the seamless steel tube was subjected to quenching and tempering treatment and the tensile test specimen was sampled therefrom.

TABLE 1Inventive orChemical Compositions (mass %, Residuals of Fe and Impurities)Test No.Steel No.ComparativeCSiMnPSCrMoAlN11Inventive Steel0.240.250.920.0120.0020.510.480.0100.005022Inventive Steel0.270.090.810.0230.0060.601.930.0100.010033Inventive Steel0.240.351.210.0180.0090.750.520.0100.050044Inventive Steel0.150.751.300.0180.0061.230.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com