Combustor and cap assemblies for combustors in a gas turbine

a gas turbine and combustible technology, applied in the combustion process, hot gas positive displacement engine plant, lighting and heating apparatus, etc., can solve the problems of excess cap assembly hardware having the lower rated hours of operation, and thus constitute stranded assets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

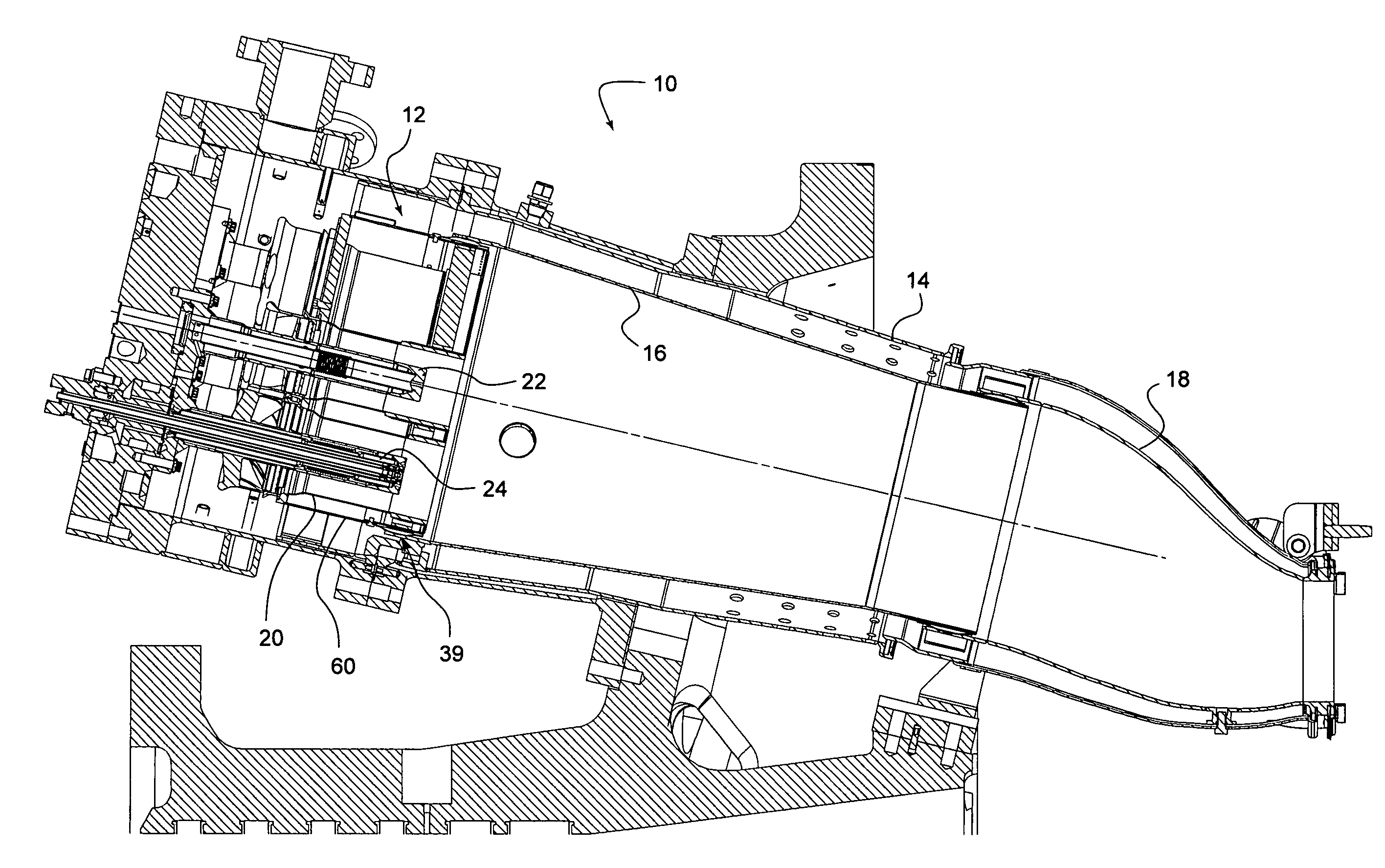

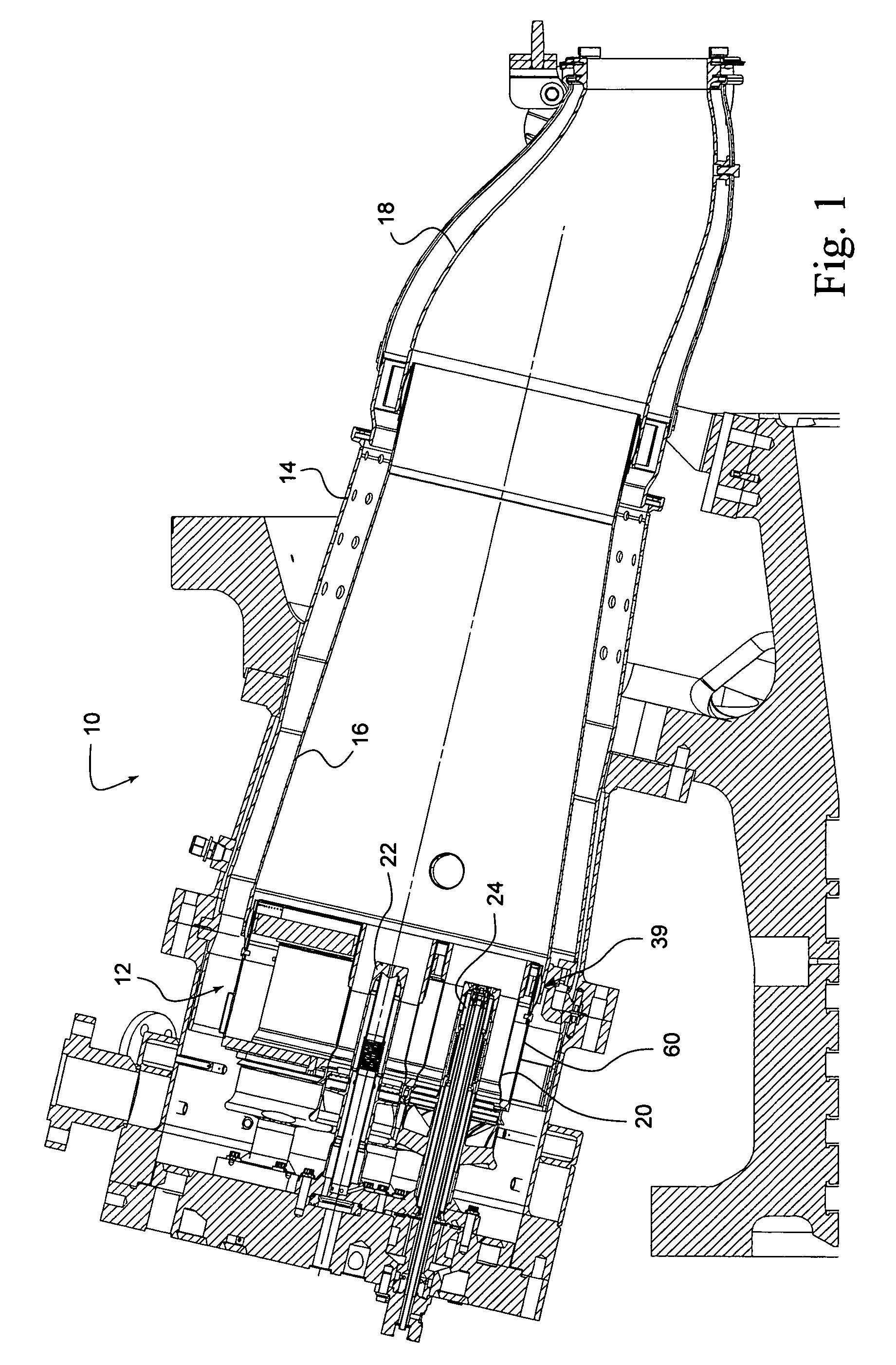

[0018] Referring now to the drawings, particularly to FIG. 1, there is illustrated a combustor generally designated 10 for a gas turbine. Combustor 10 includes a cap assembly generally designated 12 at a forward end of the combustor. As is conventional, combustor 10 includes a flow sleeve 14, a combustor liner 16 and a transition piece 18. Additionally, the cap assembly 12 includes a plurality of burner tubes 20 which form an annular array of tubes about the axis of the combustor and about a central fuel nozzle 22. Each burner tube 20 also houses a fuel nozzle 24 illustrated in FIG. 1. Typically, compressor discharge air is supplied to the burner tubes and fuel nozzle for mixing with fuel to enable combustion, the combustion gases flowing through the transition piece 18 into the turbine to extract work from the gases.

[0019] The burner tubes 20 typically have piston seals 28 for sealing about the burner tubes and to the fuel nozzle which is received within the burner tubes. Prior bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com