Calibration of xx, yy and zz induction tool measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

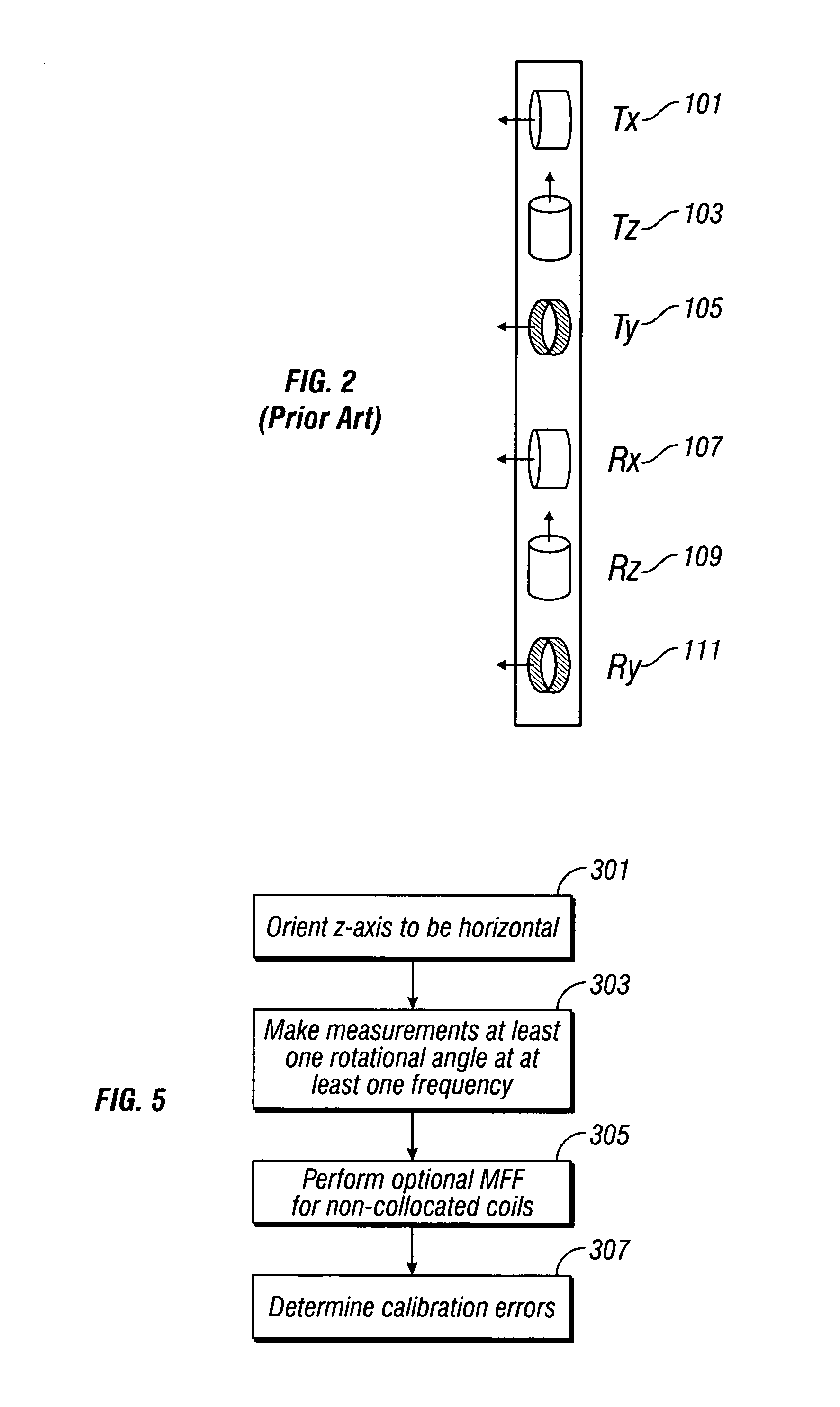

[0024] Referring now to FIG. 1, an electromagnetic induction well logging instrument 10 is shown disposed in a wellbore 2 drilled through earth formations. The earth formations are shown generally at 4. The instrument 10 can be lowered into and withdrawn from the wellbore 2 by means of an armored electrical cable 6 or similar conveyance known in the art. The instrument 10 can be assembled from three subsections: an auxiliary electronics unit 14 disposed at one end of the instrument 10; a coil mandrel unit 8 attached to the auxiliary electronics unit 14; and a receiver / signal processing / telemetry electronics unit 12 attached to the other end of the coil mandrel unit 8, this unit 12 typically being attached to the cable 6.

[0025] The coil mandrel unit 8 includes induction transmitter and receiver coils, as will be further explained, for inducing electromagnetic fields in the earth formations 4 and for receiving voltage signals induced by eddy currents flowing in the earth formations 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com