Fluid change system

a technology of fluid change system and fluid, which is applied in the direction of liquid handling, machines/engines, packaging goods types, etc., can solve the problems of contaminating the environment with used oil, and being susceptible to the same problems, so as to prevent the contamination of the environment and facilitate the connection/disconnect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

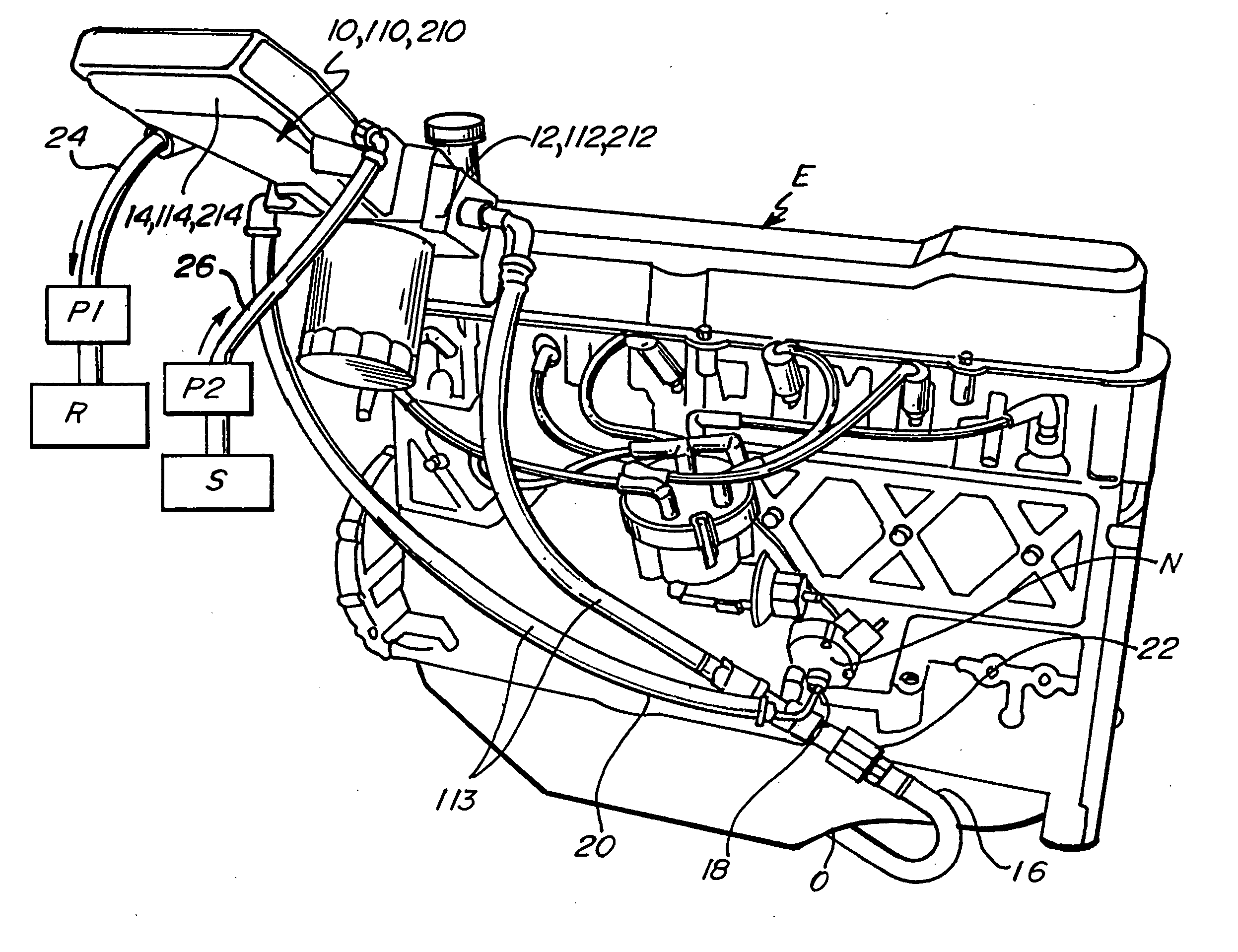

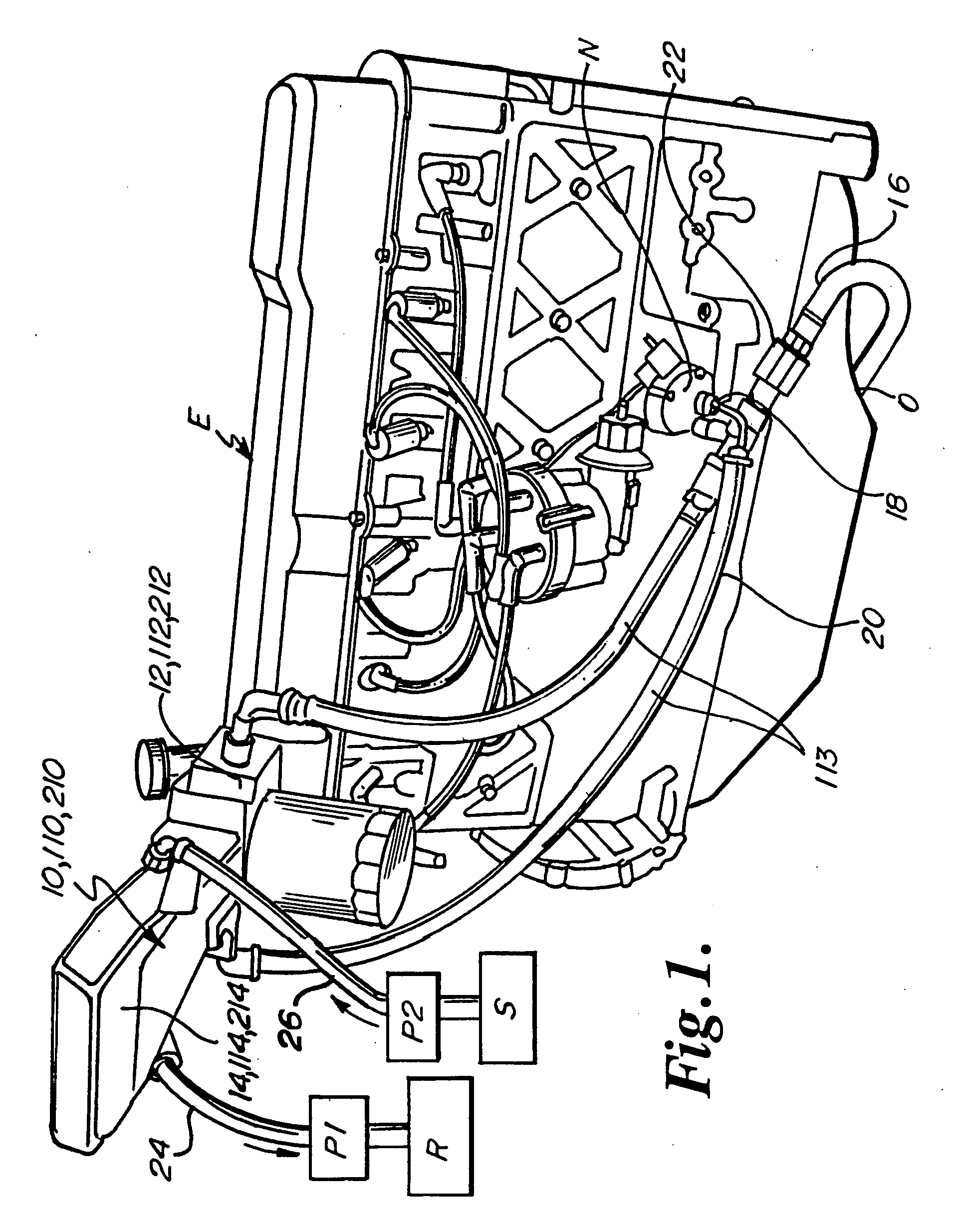

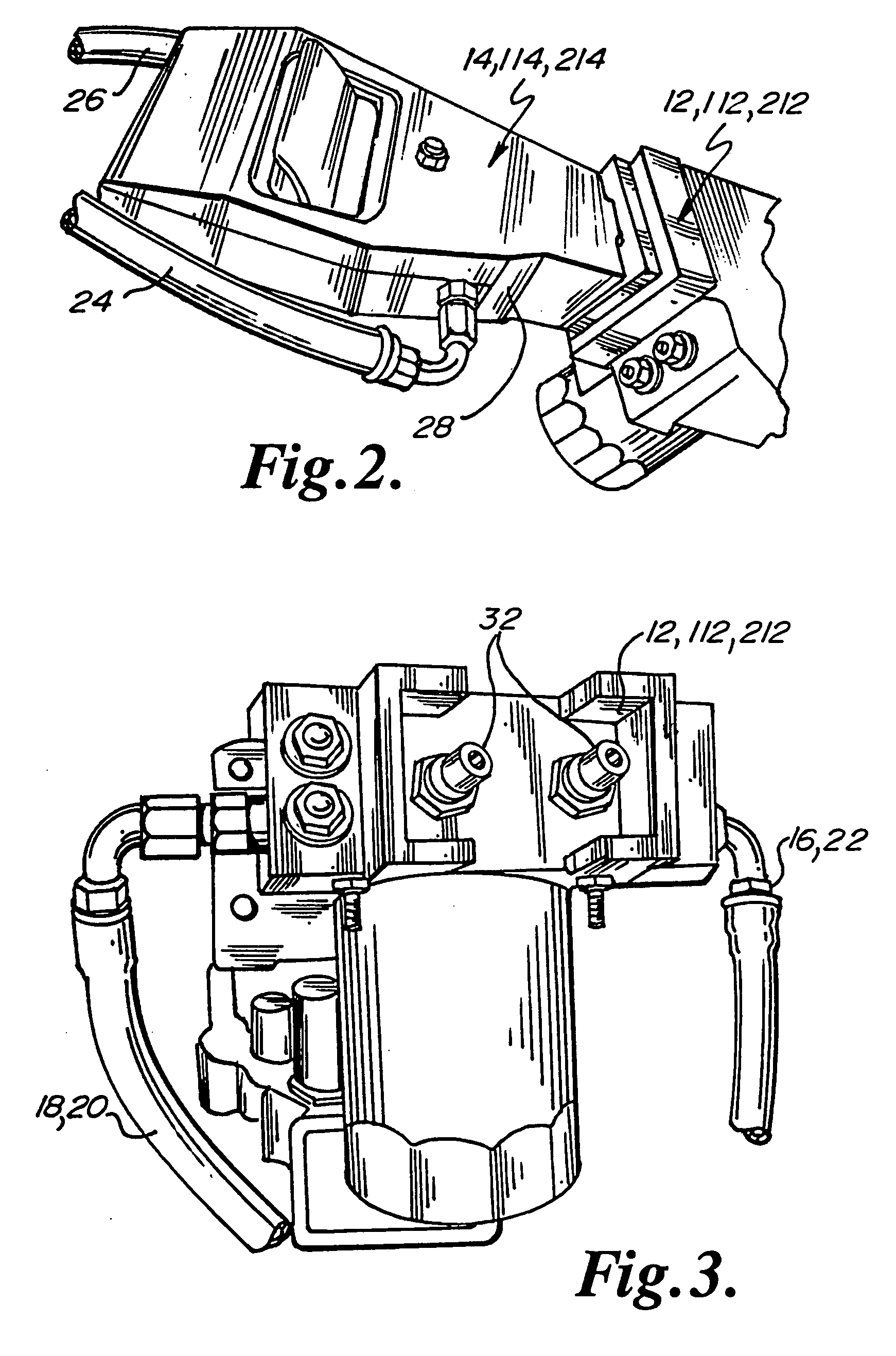

[0017] The fluid change apparatus of the present invention is generally shown in the Figures as reference numerals 10, 110, 210.

[0018] In one aspect (FIG. 1), the apparatus 10 comprises a first portion 12 adapted to be connected to an engine E and a second portion 14 mating with the first portion 12 and adapted to be connected to a source S of new fluid and to a receptacle R for old fluid.

[0019] Preferably, the first portion 12 is adapted to be connected to the engine by a first connection 16 to remove old fluid from the engine and by a second connection 18 to insert new fluid into the engine. Preferably, the first connection 16 and second connection 18 comprise hoses 20 and couplers 22.

[0020] Preferably, the second portion 14 is adapted to be connected to the receptacle R for old fluid by a third connection 24 to transfer old fluid to the receptacle R and is adapted to be connected to the source of new fluid S by a fourth connection 26 to transfer new fluid from the source S. Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com