Air handling unit mixing method and system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

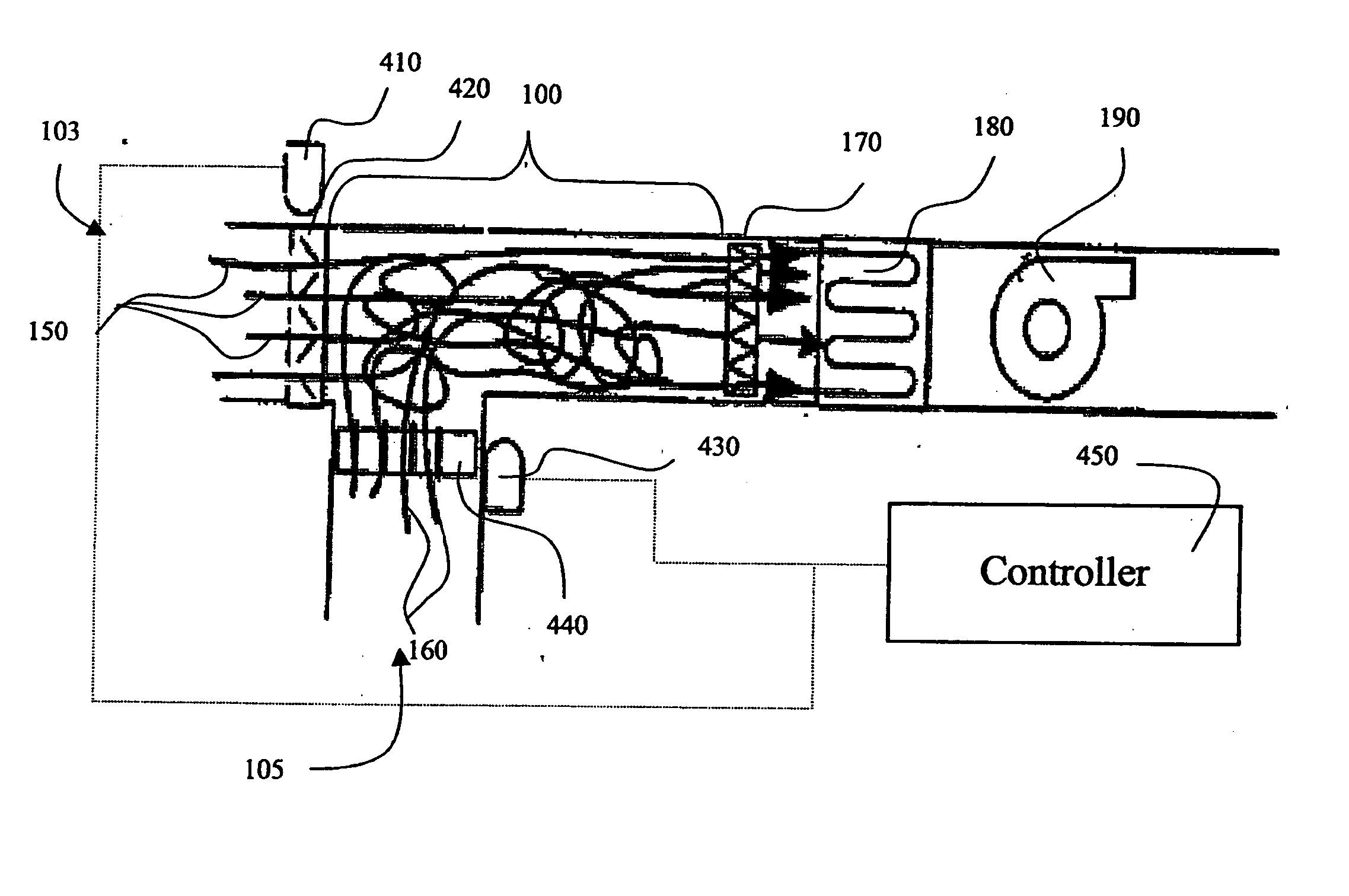

[0023]FIG. 1 schematically illustrates a known HVAC system air handling unit. The air handling unit includes a mixing space 100, which receives air from a first inlet 103 and a second inlet 105. First inlet 103 includes a first linked actuator 110, and a first parallel blade damper 120. Second inlet 105 includes a second linked actuator 130, and a second parallel blade damper 140. The first inlet air stream 150, which is preferably air brought from the outdoors, passes through first parallel blade damper 120 into the mixing space 100. The second inlet air stream 160, which is preferably return air brought from the indoor space, passes through second parallel blade damper 140 into mixing space 100. The first and second linked actuators 110 and 130 move the first and second parallel blade dampers 120 and 140 together from a single control signal. The linkage of the first and second linked actuators 110 and 130 may be a mechanical linkage or a single control signal provided to both fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com